Ordered mesoporous carbon co-loaded cerium dioxide and binuclear cobalt phthalocyanine material and preparation method thereof

A technology of ceria and nuclear cobalt phthalocyanine, applied in the field of mesoporous materials, can solve the problems of cumbersome operation process, human injury, loss, etc., and achieve the effects of high electrocatalytic activity, loss avoidance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

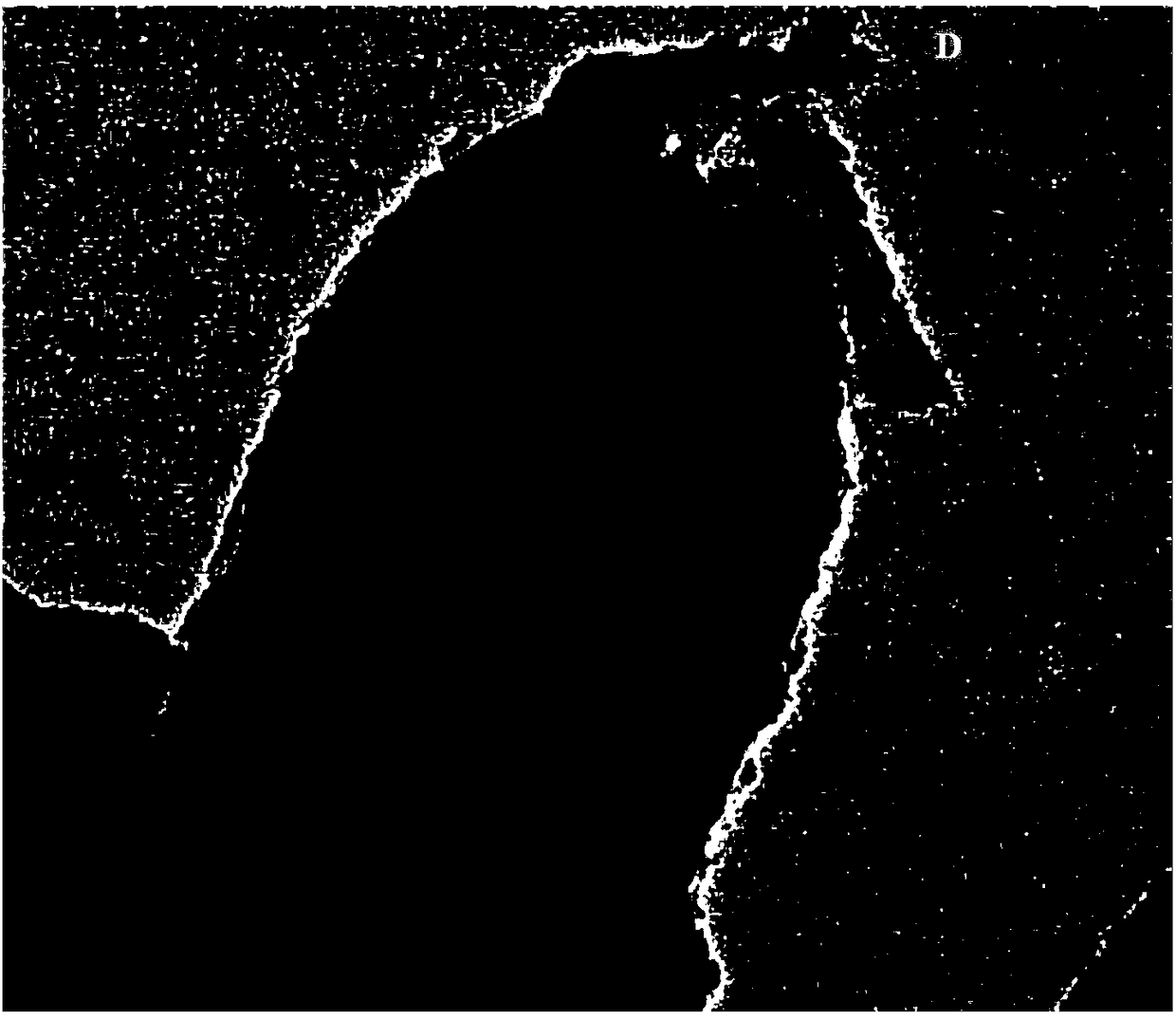

Image

Examples

Embodiment 1

[0044] The preparation of the ordered mesoporous carbon material OMC specifically includes the following steps:

[0045] OMC was prepared by using polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer (referred to as P123) as a template and tetraethyl orthosilicate (TEOS) as a silicon source.

[0046] Weigh 4g of P123, 30g of deionized water and 120g of hydrochloric acid (2mol / L) in a beaker and mix them in a beaker, stir for 4 hours under heating in an oil bath at 40°C to make them fully mixed, then add 8.5g of orthosilicic acid dropwise to the mixed solution Ethyl ester, keep the temperature constant and continue to stir for 20 hours; pour the resulting white emulsion into a polypropylene bottle, put it in an oven at 80°C for crystallization for 48 hours; filter the precipitate, wash it with deionized water, and place the solid in Dry in an oven at 60°C for 10 hours; finally put the dried solid into a box-type resistance furnace to raise the temperature...

Embodiment 2

[0050] CeO2-doped ordered mesoporous carbon material 3%CeO 2 The preparation of / OMC (3% is the massfraction that cerium element occupies OMC), specifically comprises the steps:

[0051] OMC was prepared by using polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer (referred to as P123) as a template and tetraethyl orthosilicate (TEOS) as a silicon source.

[0052] Mix 4g of P123, 30g of deionized water and 120g of hydrochloric acid (2mol / L) in a beaker, stir for 5 hours under heating in an oil bath at 50°C to make it fully mixed, and then add 8.5g of ethyl orthosilicate dropwise to the mixed solution ester, keep the temperature constant and continue to stir for 18 hours; pour the obtained white emulsion into a polypropylene bottle, put it in an oven at 90°C for crystallization for 50 hours; filter the precipitate, wash it with deionized water, and place the obtained solid in an oven Dry at 70°C for 11 hours; finally put the dried solid into a box-type...

Embodiment 3

[0057] CeO2-doped ordered mesoporous carbon material 6%CeO 2 The preparation of / OMC (6% is the massfraction that cerium element occupies OMC), specifically comprises the steps:

[0058] OMC was prepared by using polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer (referred to as P123) as a template and tetraethyl orthosilicate (TEOS) as a silicon source.

[0059] Mix 4g of P123, 30g of deionized water and 120g of hydrochloric acid (1mol / L) in a beaker, stir for 5 hours under heating in an oil bath at 60°C to make it fully mixed, and then add 8.5g of ethyl orthosilicate dropwise to the mixed solution ester, keep the temperature constant and continue to stir for 22 hours; pour the obtained white emulsion into a polypropylene bottle, put it in an oven at 100°C for crystallization for 54 hours; filter the precipitate, wash it with deionized water, and place the obtained solid in an oven Dry at 80°C for 12 hours; finally put the dried solid into a box-typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com