Titanium alloy surface high-temperature-resisting coating and preparation method thereof

A titanium alloy, high temperature resistant technology, applied in metal material coating process, coating and other directions, can solve the problem of low coating hardness and wear resistance, coating thickness, hardness, wear resistance, high temperature oxidation resistance difficult Balanced improvement, limitations and other issues, to achieve the effect of increased coating thickness, excellent high temperature oxidation resistance, and uniform mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

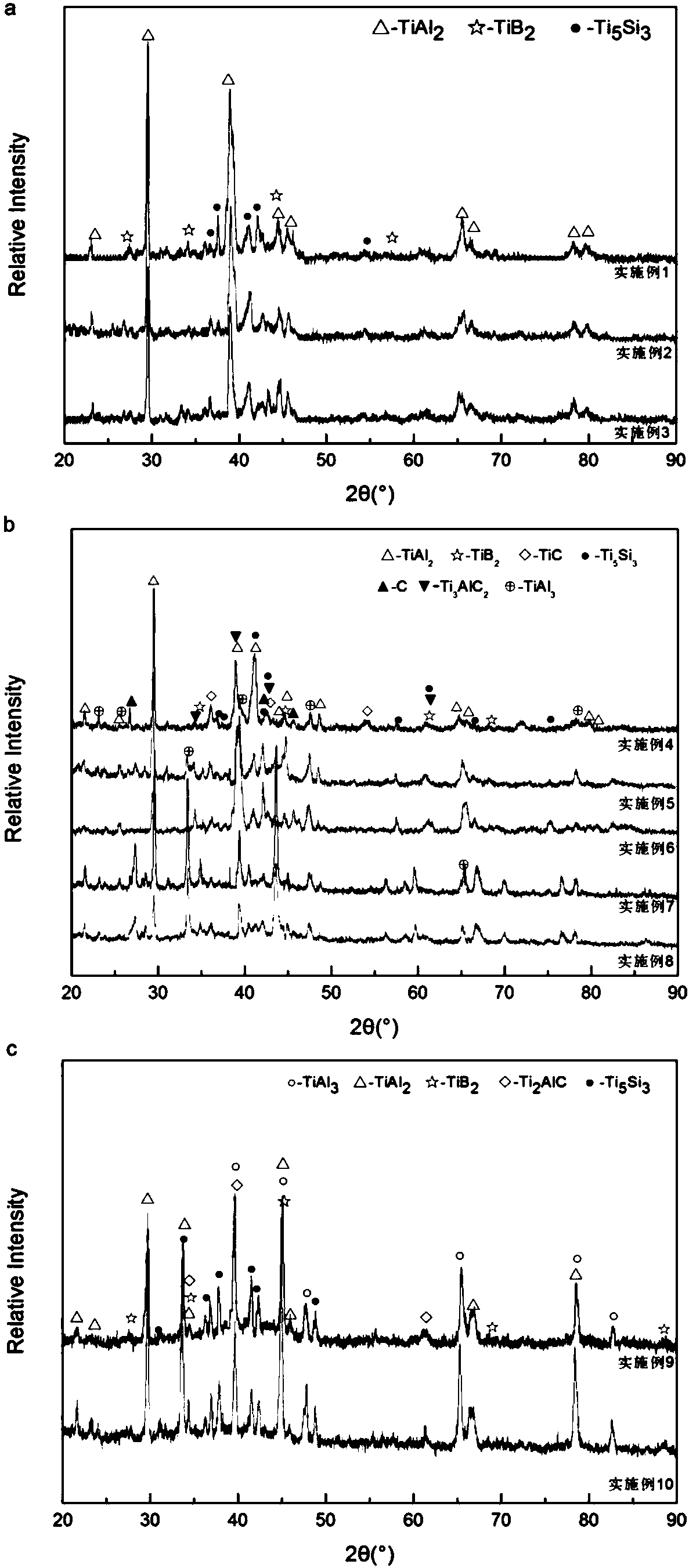

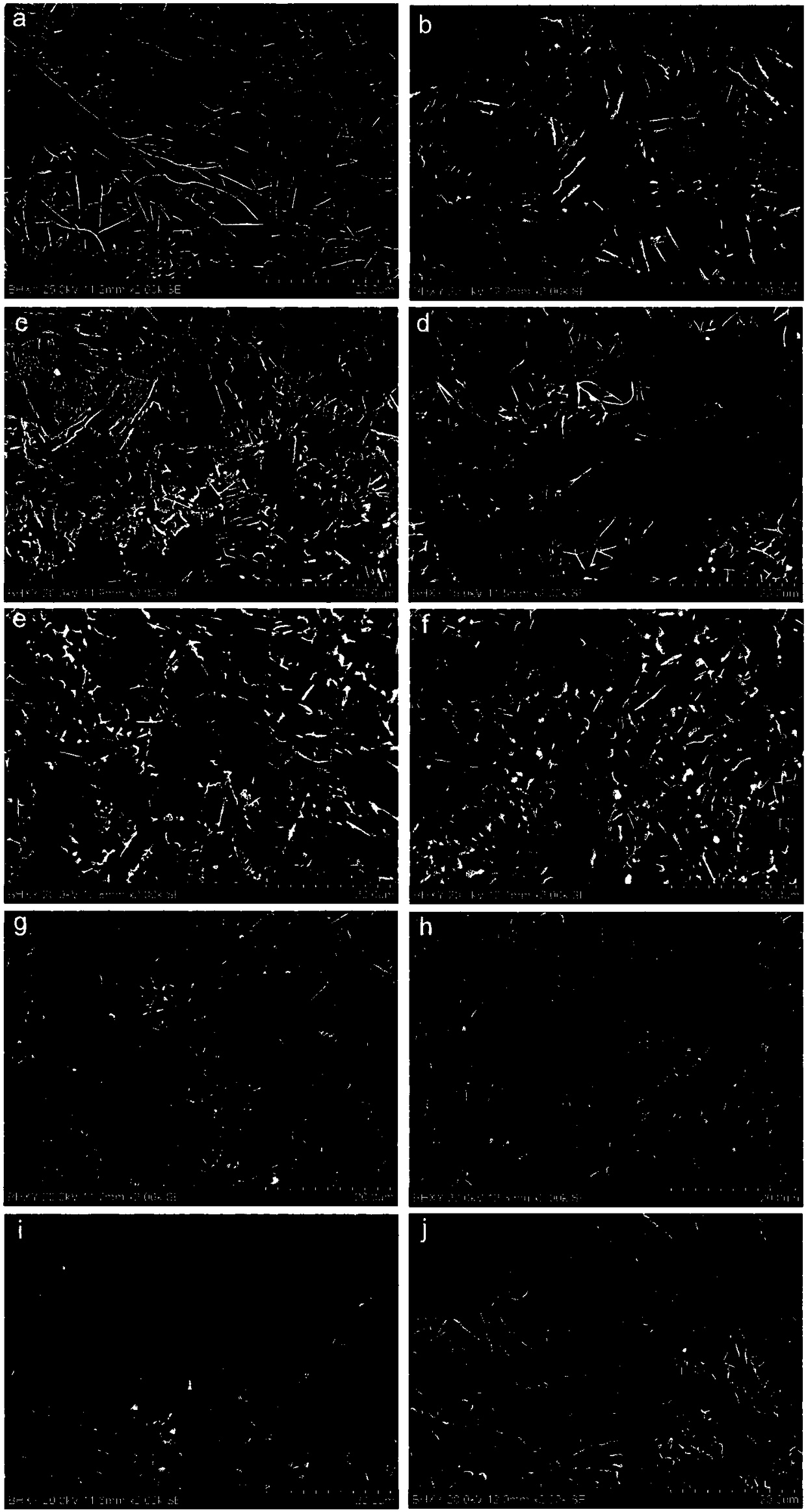

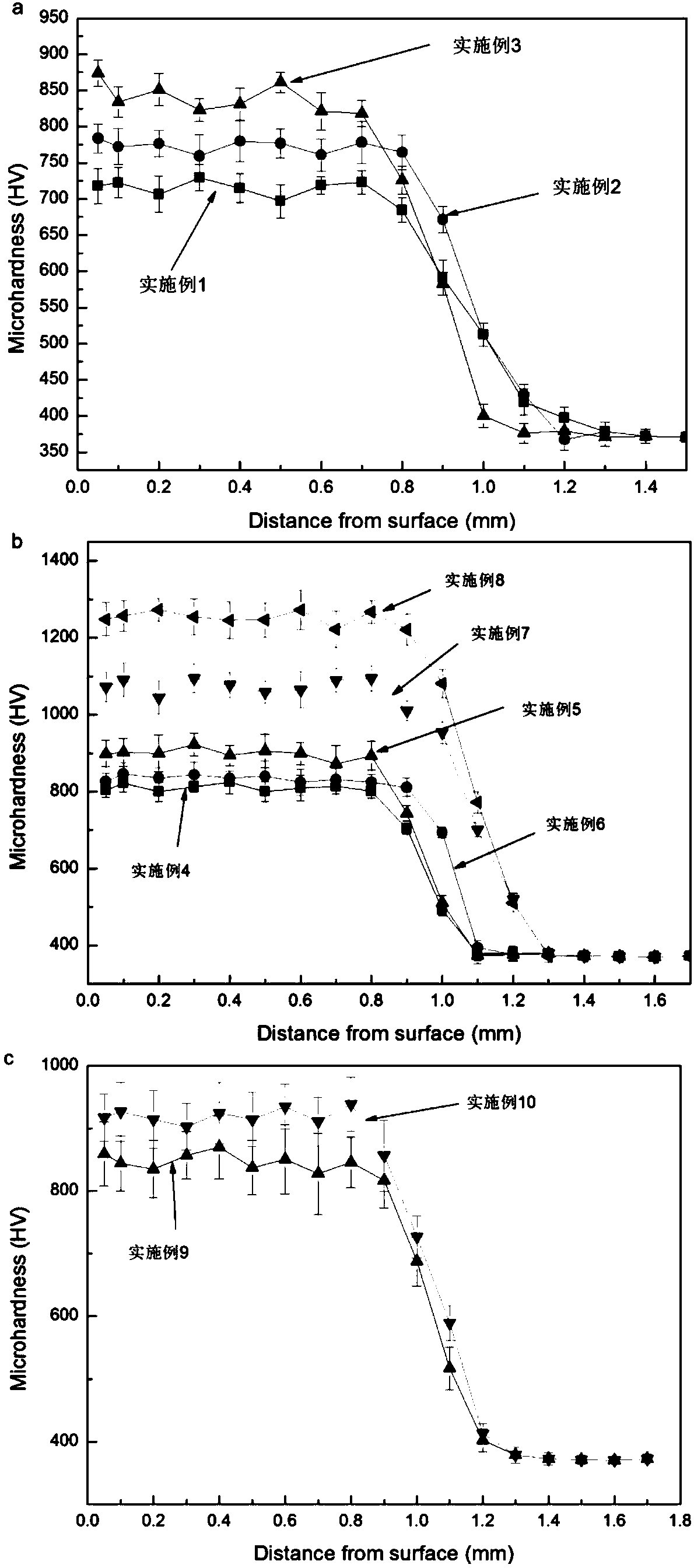

Embodiment 1

[0046] A method for preparing a high temperature resistant coating on a titanium alloy surface, comprising the following steps:

[0047] (1) The raw material and proportion of the coating are: 65% Al-20% Nb-10% Si-5% B, and the powder is mixed evenly with a ball mill for use.

[0048] (2) Preparation of titanium alloy matrix material: the Ti-6Al-4V titanium alloy was polished with sandpaper to expose the metallic luster, the grease on the surface was removed with acetone, ultrasonically cleaned in alcohol, and dried for later use.

[0049] (3) Pass high-purity argon gas into the bottom of the semi-closed container, so that the entire container is an argon atmosphere.

[0050] (4) Presetting the powder in step (1) on the surface of the alloy in step (2), with a preset thickness of 0.8-1.0mm. Place the pre-powdered sample on a fixed step in the container.

[0051] (5) Preheating with laser beam scanning, using CO 2 The gas laser performs a laser alloying test on the sample pr...

Embodiment 2

[0053] Same as Example 1, the difference lies in: the coating raw material and the proportion are: 60%Al-20%Nb-10%Si-10%B.

Embodiment 3

[0055] Same as Example 1, the difference lies in: the original coating material and the proportion are: 55%Al-20%Nb-10%Si-15%B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com