Method for comprehensive recovery of lead, mercury and selenium in copper smelting acid mud

A technology for copper smelting and acid sludge, which is applied in the field of comprehensive recovery of selenium, mercury, and lead in copper smelting acid sludge, can solve the problems of adverse effects of selenium recovery and purification, complex composition of copper smelting acid sludge, complicated technological process, etc. It is difficult to deal with mercury-containing flue gas, improving separation efficiency and treatment effect, and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

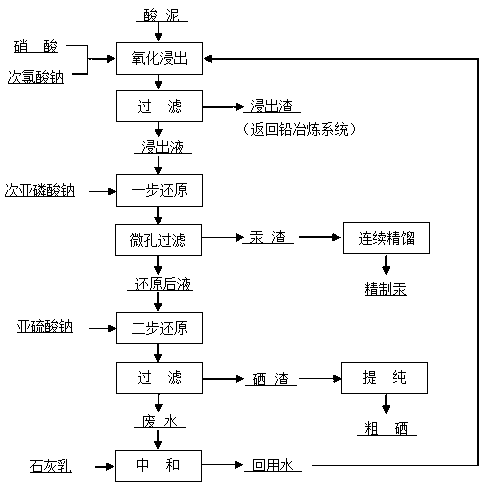

Image

Examples

Embodiment 1

[0028] The chemical composition of the copper smelting acid sludge treated in this embodiment includes: Pb 53.64-57.7%, Se 1.03-2.52%, Hg 0.70-1.31%, Cu 0.21%-0.28, As 0.13-0.34%.

[0029] A method for comprehensively recovering lead, mercury and selenium in copper smelting acid mud, specifically comprising the following steps:

[0030] 1) Mix 20g of copper smelting acid mud with 1.5mol / L nitric acid solution at a liquid-solid ratio of 5:1, gradually add 1.0mol / L sodium hypochlorite solution at 20vol% to carry out oxidation leaching reaction, stir and leaching for 60min at room temperature, and the stirring rate is 500r / min to obtain a mixed solution containing mercuric chloride and selenic acid. The chemical reaction of the leaching process is as follows:

[0031] HgSe+3NaClO+2HNO 3 →HgCl 2 +NaCl+H 2 SeO 3 +2NaNO 3,

[0032] 2) Separating the leachate obtained in step 1) into solid-liquid, the oxidizable selenium and mercury in the acid mud enter the leachate in a solu...

Embodiment 2

[0038] The chemical composition of the copper smelting acid sludge treated in this embodiment includes: Pb 53.64-57.7%, Se 1.03-2.52%, Hg 0.70-1.31%, Cu 0.21%-0.28, As 0.13-0.34%.

[0039] A method for comprehensively recovering lead, mercury and selenium in copper smelting acid mud, specifically comprising the following steps:

[0040] 1) Mix 20g of copper smelting acid mud with 1.2mol / L nitric acid solution at a liquid-solid ratio of 6:1, gradually add 1.0mol / L sodium hypochlorite solution at 15vol% to carry out oxidation leaching reaction, stir and leaching for 60min at room temperature, and the stirring rate is 500r / min to obtain a mixed solution containing mercuric chloride and selenic acid. The chemical reaction of the leaching process is as follows:

[0041] HgSe+3NaClO+2HNO 3 →HgCl 2 +NaCl+H 2 SeO 3 +2NaNO 3,

[0042] 2) Separating the leachate obtained in step 1) into solid-liquid, the oxidizable selenium and mercury in the acid mud enter the leachate in a solu...

Embodiment 3

[0048] The chemical composition of the copper smelting acid sludge treated in this embodiment includes: Pb 53.64-57.7%, Se 1.03-2.52%, Hg 0.70-1.31%, Cu 0.21%-0.28, As 0.13-0.34%.

[0049] A method for comprehensively recovering lead, mercury and selenium in copper smelting acid mud, specifically comprising the following steps:

[0050] 1) Mix 20g of copper smelting acid mud with 1.5mol / L nitric acid solution at a liquid-solid ratio of 6:1, gradually add 1.0mol / L sodium hypochlorite solution at 20vol% to carry out oxidation leaching reaction, stir and leaching for 45min at room temperature, and the stirring rate is 500r / min to obtain a mixed solution containing mercuric chloride and selenic acid. The chemical reaction of the leaching process is as follows:

[0051] HgSe+3NaClO+2HNO 3 →HgCl 2 +NaCl+H 2 SeO 3 +2NaNO 3,

[0052] 2) Separating the leachate obtained in step 1) into solid-liquid, the oxidizable selenium and mercury in the acid mud enter the leachate in a solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com