Quantum dot light emitting diode based on yttrium-doped zinc oxide electron transport layer and preparation method thereof

A technology of yttrium-doped zinc oxide and electron transport layer, which is applied in the field of quantum dot light-emitting diodes and its preparation, to achieve the effects of promoting research and development, improving luminous efficiency, and realizing simple and feasible processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

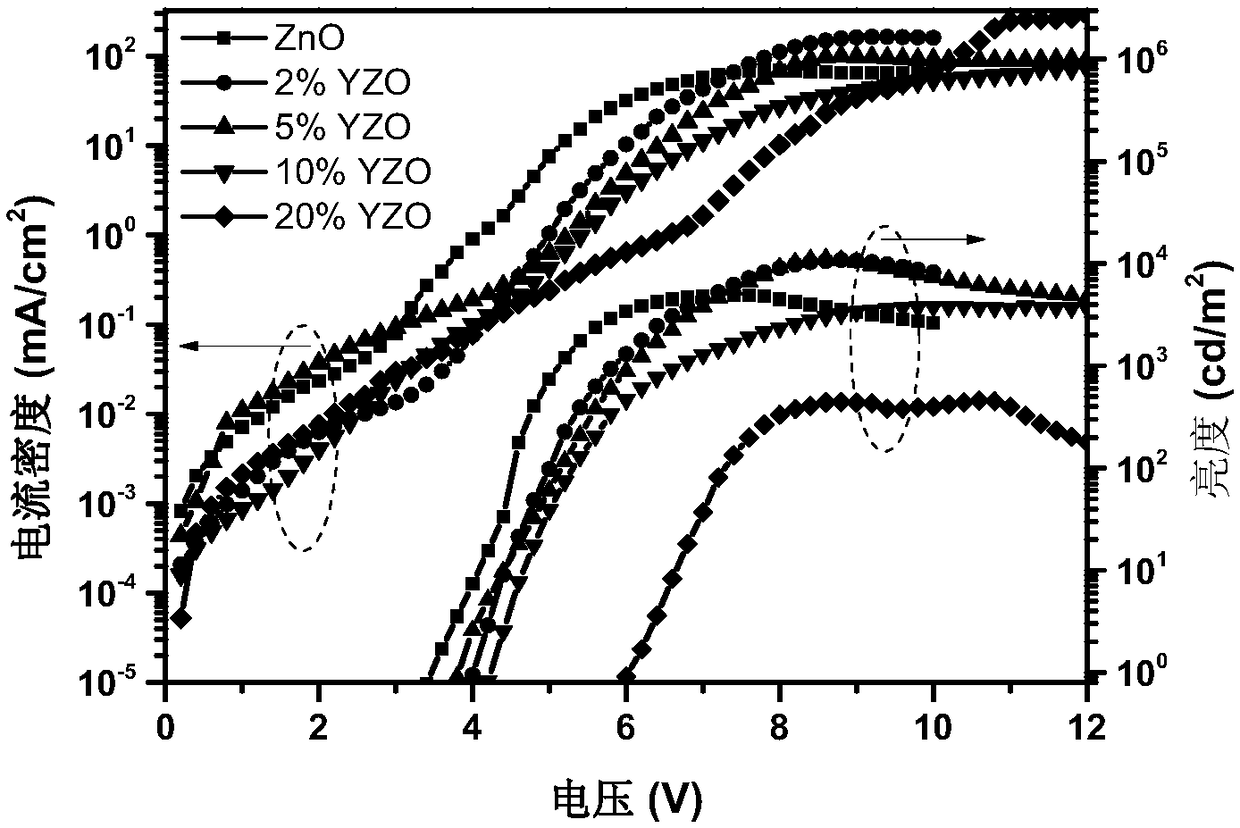

[0050] like figure 1 As shown, the quantum dot light-emitting diodes prepared in this implementation, the structure from bottom to top is the hole injection layer 12 deposited on the ITO glass, the hole transport layer 13, the quantum dot light-emitting layer 14, yttrium-doped zinc oxide nanoparticles Electron transport layer 15 and metal electrode layer 16. Its preparation includes the following steps:

[0051] (1) Cleaning treatment of ITO glass: use methanol, acetone, absolute ethanol and deionized water to carry out ultrasonic cleaning to ITO glass respectively for 30 minutes respectively, and the ITO glass sheet after cleaning is blown dry with the dry nitrogen gas through filtering, to drying The final ITO glass sheet is subjected to UV-ozone treatment, and the effect of UV-ozone treatment is to improve the surface wettability of the ITO glass sheet and increase the work function of the transparent conductive film;

[0052] (2) PEDOT / PSS aqueous solution is spin-coated...

Embodiment 2

[0064] The quantum dot light-emitting diode prepared in this implementation includes the following steps:

[0065] (1) Cleaning of FTO glass: Ultrasonic cleaning of FTO glass was carried out for 30 minutes with methanol, acetone, absolute ethanol and deionized water successively, and the FTO glass sheet after cleaning was blown dry with filtered dry nitrogen. The final FTO glass sheet is subjected to ultraviolet ozone treatment;

[0066] (2)MoO 3 Dissolved in absolute ethanol to form MoO 3 ethanol solution, MoO 3 Ethanol solution was spin-coated on the surface of FTO glass after ultraviolet ozone treatment to prepare hole injection layer, MoO 3 The mass concentration of ethanol solution is 10mg / mL, MoO 3 The spin-coating speed of ethanol solution spin-coating is 3500rpm, and the spin-coating time is 1 minute, and the spin-coated MoO 3 The conductive film is heat-treated at 50° C. for 30 minutes to obtain a hole injection layer, and the thickness of the hole injection laye...

Embodiment 3

[0079] The quantum dot light-emitting diode prepared in this implementation includes the following steps:

[0080] (1) Cleaning treatment of ATO glass: use methanol, acetone, absolute ethanol and deionized water to carry out ultrasonic cleaning respectively to ATO glass for 30 minutes respectively, and the ATO glass sheet after cleaning is blown dry with dry nitrogen through filtering, to drying The final ATO glass sheet is subjected to UV ozone treatment;

[0081] (2) WO 3 Dissolved in absolute ethanol to form WO 3 Ethanol solution was spin-coated on the surface of ATO glass after ultraviolet ozone treatment to prepare hole injection layer, WO 3 The mass concentration of ethanol solution is 10mg / mL, WO 3 The spin-coating speed of ethanol solution spin-coating is 4000rpm, and the spin-coating time is 2 minutes. 3 The conductive film is heat-treated at 50° C. for 30 minutes to obtain a hole injection layer, and the thickness of the hole injection layer is 30 nm;

[0082] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com