Method for extracting sodium dimethyl isophthalate-5-sulfonate, sodium sulfate and pure water from sodium dimethyl isophthalate-5-sulfonate process wastewater

A three-monomer, sodium sulfate technology, used in alkali metal sulfite/sulfate purification, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of low adsorption efficiency, insufficient utilization of other components, yield Low and other problems, to achieve the effect of zero emission and cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

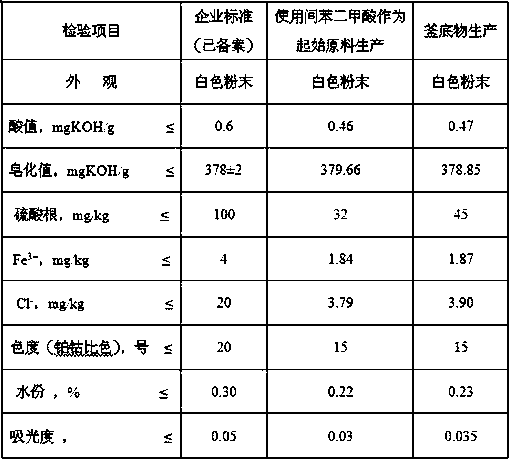

Examples

Embodiment 1

[0050] Embodiment 1 A kind of method for the comprehensive utilization of three-monomer production process wastewater

[0051] Include the following steps:

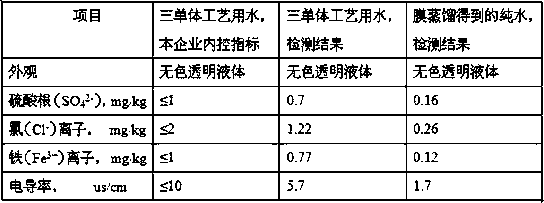

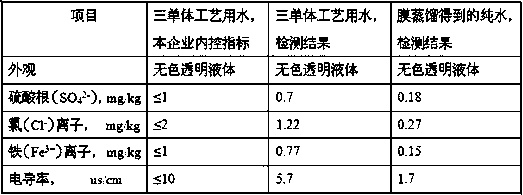

[0052] Step 1. Concentrate and prepare pure water

[0053] The wastewater after methanol removal is evaporated and concentrated by the MVR device to obtain pure water conforming to the production of three monomers and containing three monomers (dimethyl isophthalate-5-sodium sulfonate), monomethyl isophthalate- Concentrate of organic substances such as sodium 5-sulfonate and sodium 5-sulfonate isophthalate.

[0054] The specific operation is as follows:

[0055] (1) Feed

[0056] The wastewater after methanol removal is pumped to the raw material tank of the system, and the wastewater after methanol removal is pumped into the plate heat exchanger from the raw material tank by the feed pump, and the flow rate of the pump is controlled to be 2m 3 / h, outlet pressure 0.2MPa.

[0057] (2) Heat exchange

[0058] The wast...

Embodiment 2

[0102] Embodiment 2 A kind of method for the comprehensive utilization of three-monomer production process wastewater

[0103] Include the following steps:

[0104] Step 1. Concentrate and prepare pure water

[0105] The wastewater after methanol removal is evaporated and concentrated by the MVR device to obtain pure water conforming to the production of three monomers and containing three monomers (dimethyl isophthalate-5-sodium sulfonate), monomethyl isophthalate- Concentrate of organic substances such as sodium 5-sulfonate and sodium 5-sulfonate isophthalate.

[0106] The specific operation is as follows:

[0107] (1) Feed

[0108] The wastewater after methanol removal is pumped to the raw material tank of the system, and the wastewater after methanol removal is pumped into the plate heat exchanger from the raw material tank by the feed pump, and the flow rate of the pump is controlled to be 3m 3 / h, outlet pressure 0.25MPa.

[0109] (2) Heat exchange

[0110] The was...

Embodiment 3

[0150] Embodiment 3 A kind of method for the comprehensive utilization of three-monomer production process wastewater

[0151] Include the following steps:

[0152] Step 1. Concentrate and prepare pure water

[0153] The wastewater after methanol removal is evaporated and concentrated by the MVR device to obtain pure water conforming to the production of three monomers and containing three monomers (dimethyl isophthalate-5-sodium sulfonate), monomethyl isophthalate- Concentrate of organic substances such as sodium 5-sulfonate and sodium 5-sulfonate isophthalate.

[0154] The specific operation is as follows:

[0155] (1) Feed

[0156] The wastewater after methanol removal is pumped to the raw material tank of the system, and the wastewater after methanol removal is pumped into the plate heat exchanger from the raw material tank by the feed pump, and the flow rate of the pump is controlled to be 4m 3 / h, outlet pressure 0.3MPa.

[0157] (2) Heat exchange

[0158] The wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of recovery | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com