Method for preparing waterproof cement mortar

A technology for waterproof mortar and cement, applied in the field of preparation of cement waterproof mortar, can solve the problems of rarely using polymer emulsion, poor weather resistance and corrosion resistance of mortar, etc., to enhance hydrophobicity, reduce negative charge, and increase organic components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

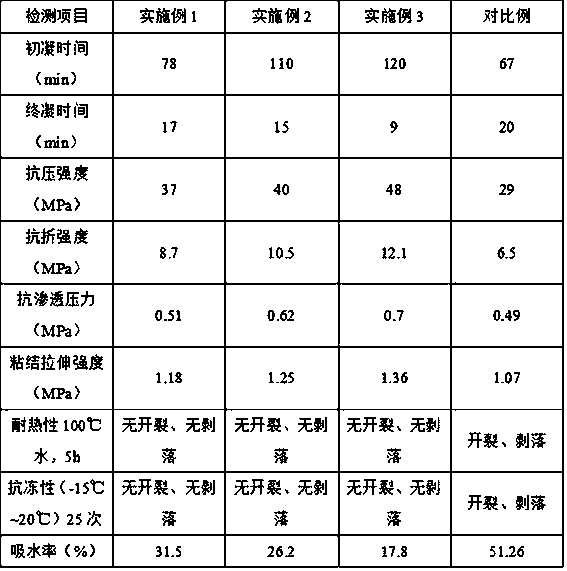

Examples

preparation example Construction

[0023] A preparation method of cement waterproof mortar, the preparation method comprises the steps of:

[0024] (1) Grind and sieve the montmorillonite to obtain the sieved product. According to parts by weight, take 30~40 parts of water, 10~15 parts of sieved product, 0.2~0.4 part of sodium carbonate, 0.03~0.08 part of Dispersant, mix water, sieve, sodium carbonate, and dispersant, stir in a constant temperature water bath at 50~60°C at 200~300r / min for 1~2h, filter to obtain filter residue, and filter residue at a temperature of 70~80 Dry at a constant temperature at ℃, grind through a 100-120 mesh sieve to obtain ground material, and set aside;

[0025] (2) In parts by weight, take 30~40 parts of ethanol, 10~15 parts of deionized water, 3~4 parts of polydimethylsiloxane, 3~4 parts of ammonia water, 1~2 parts of nano silicon dioxide , put ethanol, deionized water, polydimethylsiloxane, and nano-silicon dioxide into a container, stir for 30-40min at a temperature of 50-65°C...

Embodiment 1

[0029] The dispersant is sodium hexametaphosphate.

[0030] The emulsifier is obtained by mixing oleic acid and sorbitan trioleate evenly at a mass ratio of 1:0.8.

[0031] The initiator is potassium persulfate.

[0032] A preparation method of cement waterproof mortar, the preparation method comprises the steps of:

[0033] (1) Grind and sieve the montmorillonite to obtain the sieved product. In parts by weight, take 30 parts of water, 10 parts of the sieved product, 0.2 part of sodium carbonate, and 0.03 part of dispersant, and sieve the water, Mix the mixture, sodium carbonate, and dispersant, stir in a constant temperature water bath at 50°C at 200r / min for 1 hour, filter to obtain a filter residue, dry the filter residue at a constant temperature at a temperature of 70°C, and grind through a 100-mesh sieve to obtain a grind, which is set aside ;

[0034] (2) In parts by weight, take 30 parts of ethanol, 10 parts of deionized water, 3 parts of polydimethylsiloxane, 3 part...

Embodiment 2

[0038] The dispersant is sodium hexametaphosphate.

[0039] The emulsifier is obtained by mixing oleic acid and sorbitan trioleate evenly at a mass ratio of 1:0.8.

[0040] The initiator is ammonium persulfate.

[0041] A preparation method of cement waterproof mortar, the preparation method comprises the steps of:

[0042] (1) Grind and sieve the montmorillonite to obtain the sieved product. In parts by weight, take 35 parts of water, 12 parts of the sieved product, 0.3 part of sodium carbonate, and 0.05 part of dispersant, and sieve the water, Mix the powder, sodium carbonate, and dispersant, stir in a constant temperature water bath at 55°C at 250r / min for 1h, filter to obtain a filter residue, dry the filter residue at a constant temperature at a temperature of 75°C, and grind through a 110-mesh sieve to obtain a grind, which is set aside ;

[0043] (2) In parts by weight, take 35 parts of ethanol, 12 parts of deionized water, 3 parts of polydimethylsiloxane, 3 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com