Chlorine dioxide preoxidation method of sulfur-contained gold ores

A chlorine dioxide and pre-oxidation technology, applied in the direction of improving process efficiency, can solve problems such as no literature reports, and achieve the effect of good ore adaptability, excellent environmental protection performance, and industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the method of the present invention is used to oxidize single minerals such as stibnite, pyrite or arsenopyrite. Finely grind the above three kinds of single minerals to -0.074mm, adjust the slurry according to the liquid-solid mass ratio of 200:1, do not add acidity regulator, and pre-oxidize at 50°C for 1 hour. The chlorine dioxide generator uses sodium chlorite, and the activator uses tartaric acid, and the mass ratio of the two is 5:2. Under the optimal conditions of the mass ratios of sodium chlorite to stibnite, pyrite and arsenopyrite being 7:1, 15:4 and 7:2, respectively, the sulfur removal rates of the three sulfide ores were all the same. Reach more than 95%.

Embodiment 2

[0034] In this embodiment, the ore sample used is a Carlin-type gold mine in Gansu. In this type of gold ore, metal sulfides mainly composed of pyrite, stibnite, and arsenopyrite are scattered in the ore, and gold is usually wrapped in sulfide minerals in the form of fine particles or submicroscopic particles, which is difficult to obtain. Process ore. The results of its chemical composition analysis are shown in Table 1.

[0035] Table 1 raw ore multi-element analysis results (%, * gram / ton)

[0036] Au *

Ag *

Cu

Pb

Zn

Fe

C

S

Sb

As

SiO 2

Al 2 o 3

CaO

MgO

TiO 2

4.09

1.1

0.005

0.004

0.014

3.30

2.07

0.85

0.46

0.39

56.11

14.33

5.51

2.83

0.55

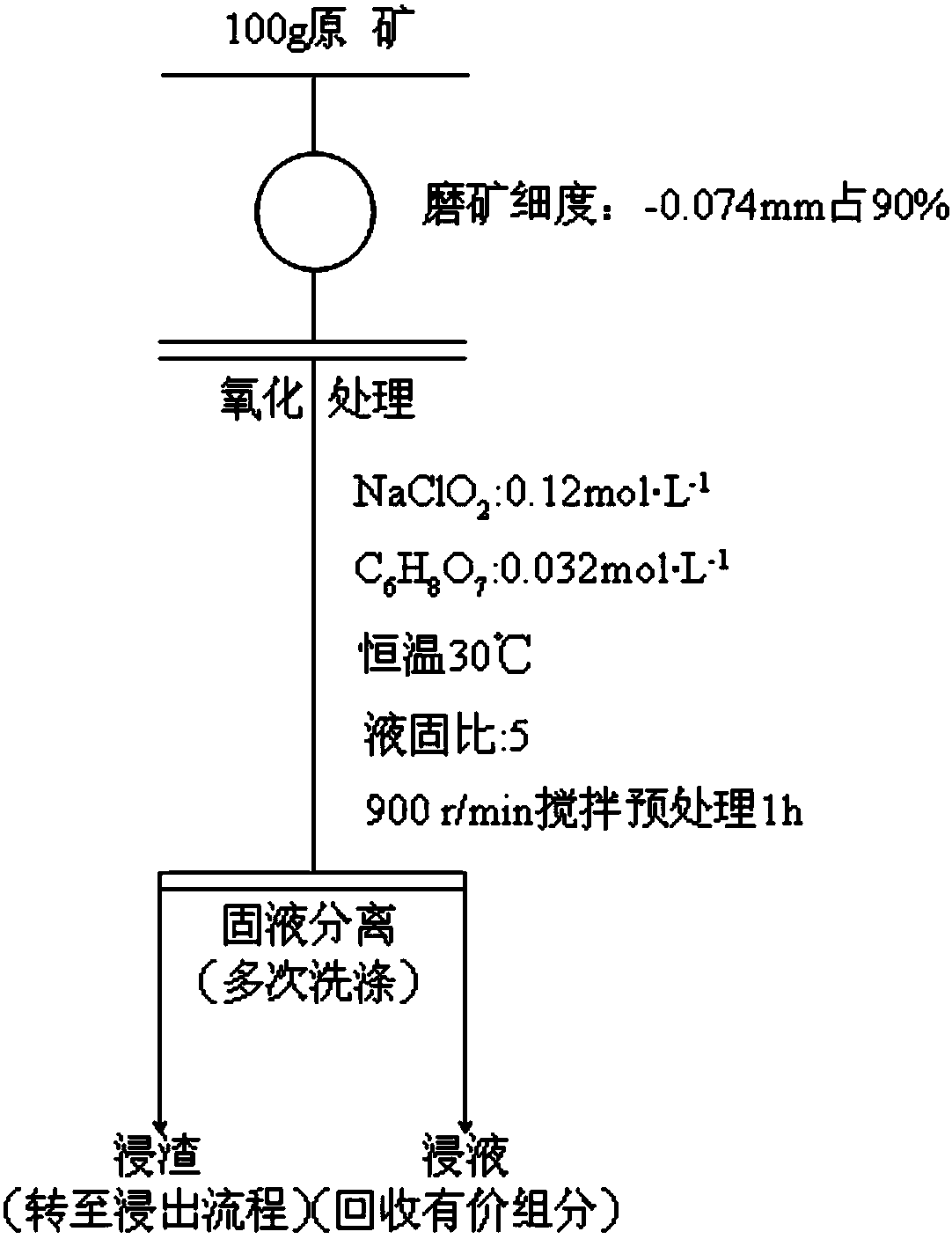

[0037] Such as figure 1 As shown, chlorine dioxide generator (sodium chlorite NaClO 2 , concentration 0.12mol L -1 ) and activator (citric acid C 6 h 8 o 7 , concentration 0.032mol L -1), the mass ratio of...

Embodiment 3

[0040] The difference from Example 2 is that the ore sample used in this example is the flotation closed-circuit gold ore of the gold ore used in Example 2. After flotation, the content of gold, silver, arsenic, iron, antimony, sulfur and other elements in the minerals increased, and the content of gangue minerals decreased accordingly. The chemical composition analysis results are shown in Table 2.

[0041] Table 2 flotation concentrate multi-element analysis results (%, * gram / ton)

[0042] Au *

Ag *

As

Sb

Fe

C

S

SiO 2

Al 2 o 3

CaO

MgO

TiO 2

56.8

8.1

5.69

3.29

15.07

1.35

17.3

34.37

14.87

3.63

2.26

0.44

[0043] Slurry the flotation concentrate according to the liquid-solid mass ratio of 50:1, adjust the acidity to pH=4 with sulfuric acid, and pre-oxidize at 50°C for 1 hour. The chlorine dioxide generator uses sodium chlorite, and the activator uses citric acid, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com