Dual-immobilized rapid-starting functional carbon source filler and preparation method thereof

A fast-starting and functional technology, applied in the field of repairing fillers, can solve the problems of not giving full play to the advantages of agricultural waste, inability to adjust flexibly, and slow start-up of the repairing process, so as to achieve good cation exchange and adsorption capacity, and avoid ammonia nitrogen concentration and chroma Elevated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

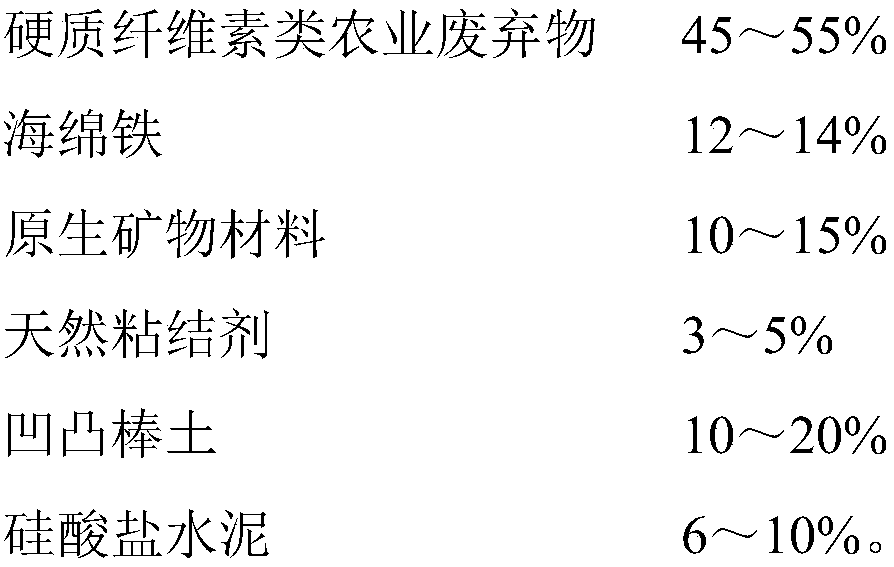

[0036]In this example, the fast-start double-immobilized quick-start functional packing used for adsorption and immobilization of groundwater pollution remediation and enhanced by indigenous efficient denitrification microorganisms is as follows:

[0037] (1) Rinse the peanut shells and walnut shells twice with clean water, ventilate and dry for 3-4 days, and set aside;

[0038] (2) pulverizing the natural cellulose raw material obtained in step (1) to 20 orders for subsequent use;

[0039] (3) Sponge iron is crushed to 80 orders for subsequent use;

[0040] (4) Mix the mixture of peanut shells and walnut shells, zeolite, safflower powder, sponge iron, attapulgite, and ordinary Portland cement in proportion and mix well, add an appropriate amount of water until the raw materials are viscous, and start extrusion Compression molding machine, the raw materials are gradually put into the feeding port, wherein the composition and mass percentage of the filler are as follows: 55% m...

Embodiment 2

[0047] In this example, the preparation process of the fast-start dual-immobilization functional filler for adsorption and immobilization of groundwater pollution remediation and enhancement of indigenous high-efficiency denitrification microorganisms is as follows:

[0048] (1) Rinse the mixture of peanut shells and walnut shells with clean water twice, ventilate and dry for 3-4 days, and set aside;

[0049] (2) pulverizing the natural cellulose raw material obtained in step (1) to 16 orders for subsequent use;

[0050] (3) Sponge iron is crushed to 70 orders for subsequent use;

[0051] (4) According to the proportion of fillers, mix peanut shell and walnut shell powder, zeolite, safflower powder, sponge iron, attapulgite, and ordinary Portland cement in proportion and mix them well, and add appropriate amount of water until the raw materials are Viscous, start the extrusion molding machine, and gradually put the raw materials into the feeding port. Among them, the composit...

Embodiment 3

[0059] In this example, the preparation process of the fast-start dual-immobilization functional filler for adsorption and immobilization of groundwater pollution remediation and enhancement of indigenous high-efficiency denitrification microorganisms is as follows:

[0060] (1) Rinse the mixture of peanut shells and walnut shells with clean water twice, ventilate and dry for 3-4 days, and set aside;

[0061] (2) pulverizing the natural cellulose raw material obtained in step (1) to 16 orders for subsequent use;

[0062] (3) Sponge iron is crushed to 90 orders for subsequent use;

[0063] (4) According to the proportion of fillers, mix peanut shell and walnut shell powder, zeolite, safflower powder, sponge iron, attapulgite, and ordinary Portland cement in proportion and mix them well, and add appropriate amount of water until the raw materials are Viscous, start the extrusion molding machine, and gradually put the raw materials into the feeding port. Among them, the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com