Waste acid recovery treatment method for sludge generated in steel wire rope plant

The technology of a steel wire rope factory and a treatment method is applied in the field of sludge waste acid recovery and treatment, which can solve the problems of difficult treatment, great harm, and large output, and achieve the effects of reducing the amount of lead and zinc precipitation and increasing the abundance of lead and zinc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The whole process is tested by treating 500kg wire rope sludge:

[0043] The composition of steel wire rope sludge is as follows: moisture content 61.9%, iron content 13.7%, lead content 0.4%, zinc content 2.6%; steel wire rope pickling waste acid composition is as follows, HCl content 9.5%, iron content 8.2%, lead content 3.7g / L , Zinc content 2.0g / L.

[0044] will be 2m 3 Add waste acid from steel wire rope pickling to the heavy metal sludge extraction reactor, add 500kg of steel wire rope sludge, and fully stir for 2 hours; the supernatant enters the reduction reactor, add 40kg of reduced iron powder, fully stir for 2 hours, and settle for 1 hour; The clear liquid enters the pH adjustment tank, and gradually adds about 200L of 20% sodium hydroxide solution dropwise to adjust the pH to 2.4; the adjusted pH solution enters the coagulation system, and gradually adds 120L of 20% sodium sulfide solution dropwise, Stir fully for 30 minutes; the supernatant is filtered to...

Embodiment 2

[0047] The whole process is tested by treating 500kg wire rope sludge:

[0048]The composition of steel wire rope sludge is as follows: moisture content 65.4%, iron content 12.3%, lead content 0.25%, zinc content 2.8%; steel wire rope pickling waste acid composition is as follows, HCl content 9.5%, iron content 8.2%, lead content 3.7g / L , Zinc content 2.0g / L.

[0049] will be 2m 3 Put the waste acid from steel wire rope pickling into the heavy metal sludge extraction reactor, add 500kg of steel wire rope sludge, and fully stir for 2 hours; the supernatant enters the reduction reactor, add 35kg of reduced iron powder, fully stir for 2 hours, and settle for 1 hour; The clear liquid enters the pH adjustment tank, and gradually adds 160L of 20% sodium hydroxide solution dropwise to adjust the pH to 2.0; the adjusted pH solution enters the coagulation system, and gradually adds 120L of 20% sodium sulfide solution dropwise to fully Stir for 30 minutes; the supernatant is filtered ...

Embodiment 3

[0052] To process 60g of steel wire rope sludge, a small laboratory experiment was carried out on the whole process:

[0053] The composition of steel wire rope sludge is as follows: moisture content 62.3%, iron content 13.5%, lead content 0.4%, zinc content 1.4%; steel wire rope pickling waste acid composition is as follows, HCl content 9.5%, iron content 8.2%, lead content 3.7g / L , Zinc content 2.0g / L.

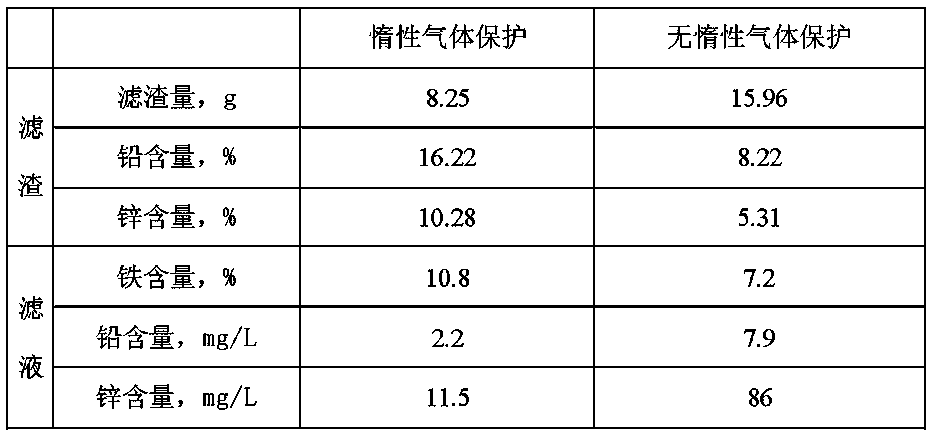

[0054] Add 300mL of steel wire rope pickling waste acid into the heavy metal sludge extraction reactor, add 60g of steel wire rope sludge, and stir for 2 hours; after filtering, the supernatant enters the reduction reactor, add 5g of reduced iron powder, and stir for 2 hours; filter Finally, in the coagulation and sedimentation device, gradually add about 15mL of 20% sodium hydroxide solution dropwise, adjust the pH to 2.4, then gradually add 15mL of 20% sodium sulfide solution dropwise, and fully stir for 30 minutes; after filtration The filter residue was washed and dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com