Photochromic micro-nano capsule with solid capsule core and preparation method of photochromic micro-nano capsule

A technology for capsule preparation and capsule core, which is applied in the field of photochromic micro-nano capsules and its preparation, can solve the problems of difficult durability of weather resistance and photo-changeability, limited application occasions, and no protection treatment, and achieves improved thermal stability. , The effect of improving the discoloration performance and prolonging the weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

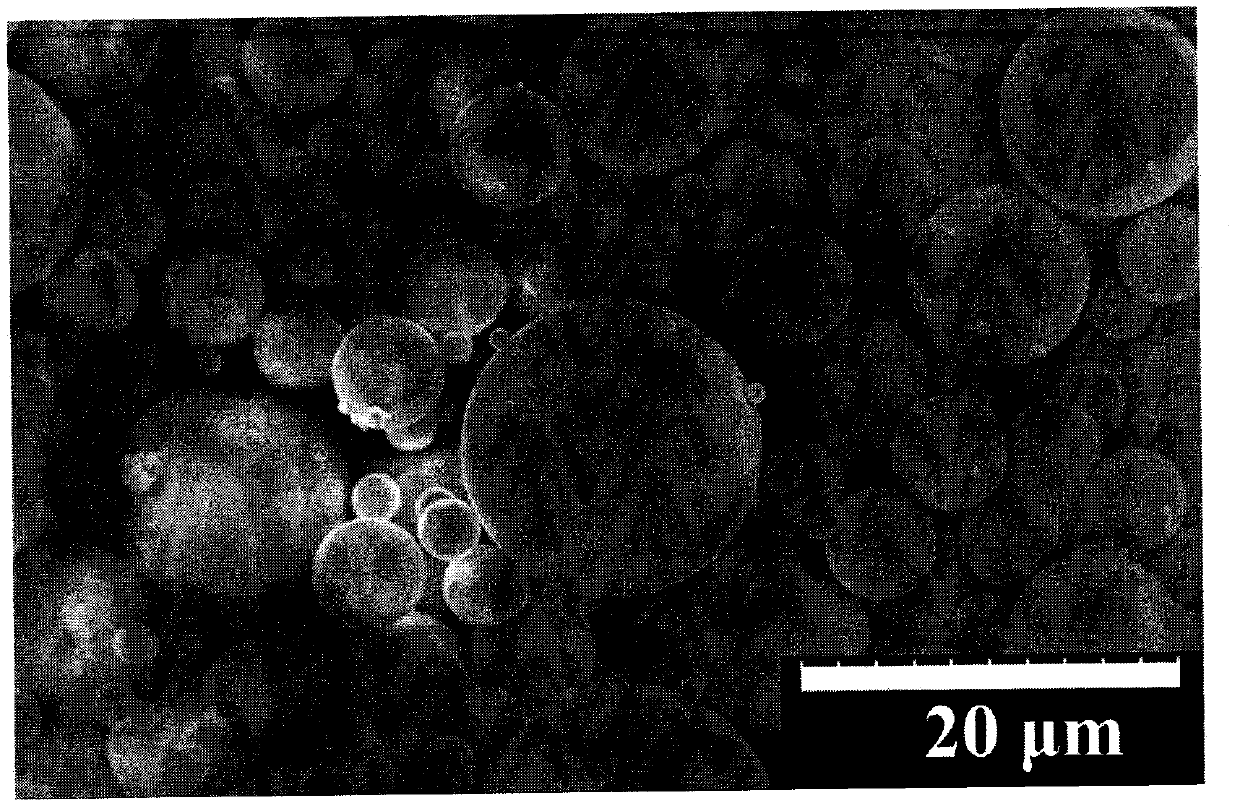

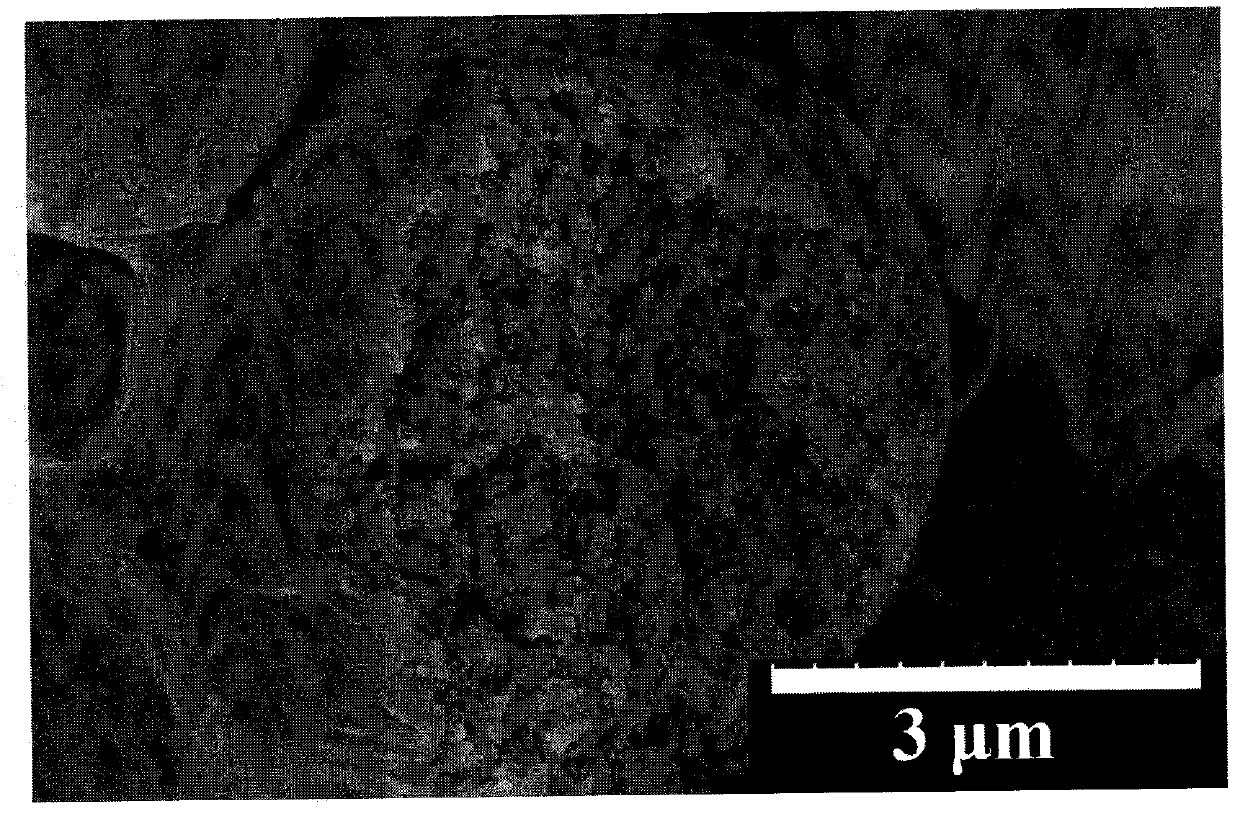

Embodiment 1

[0025]Dissolve 2g of polylactic acid, 1g of spirooxazine organic photochromic dye, 0.5g of dibutyl hydroxytoluene, 0.3g of 2-hydroxy-4-n-octyloxybenzophenone and 0.3g of phenyl 1-hydroxy-2-naphthoate in 20g of ethyl acetate, and then added to 200g of 2wt% sodium polyacrylate copolymer aqueous solution, while adding 2g of n-amyl alcohol, and emulsified at a high speed of 5000rpm for 10min to obtain a stable oil-in-water emulsion. The particle size was measured to be 1-5 microns by optical microscope observation. The above-mentioned oil-in-water emulsion was transferred to a three-necked flask, and the pH of the emulsion was adjusted to 4, and the temperature was set to 50°C. Weigh 10g of partially methylated melamine-formaldehyde prepolymer and dilute it with 5g of distilled water to form a homogeneous solution, and add it dropwise into the homogeneous emulsion with a peristaltic pump while stirring at a speed of 350rpm. Suspension of micro-nanocapsules in liquid capsule core. ...

Embodiment 2

[0028] With 1kg thermoplastic polyurethane, 1kg spiropyran organic photochromic dye, 60g tert-butyl hydroquinone, 50g resorcinol monobenzoate and 30g dibenzyl oxalate are dissolved in 20kg toluene, then join in In 100kg sodium lauryl sulfate solution, wherein containing sodium lauryl sulfate 1kg, n-octanol 1kg, Tween 60 consumption 2kg, high-speed emulsification 60min under 9000rpm rotating speed, after making stable oil-in-water emulsion, The particle size of the emulsion droplet was observed and measured by an optical microscope to be 2-15 microns. The above-mentioned oil-in-water emulsion was transferred to a three-necked flask, and the pH of the emulsion was adjusted to 4.9, and the temperature was set to 50°C. Weigh 5kg of butylated melamine formaldehyde prepolymer and dilute it with 5kg of distilled water to form a homogeneous solution, and add it dropwise into the homogeneous emulsion with a peristaltic pump while stirring at a speed of 1000rpm. Suspension of micro-nano...

Embodiment 3

[0030] 20g of polybutylene terephthalate, 10g of 2,2-di(4-formylphenyl)naphthopyran, 0.3g of dibutylhydroxytoluene, 0.5g of 2-hydroxy-4-n-octyloxydi Dissolve benzophenone and 0.1g of 1-hydroxy-2-phenyl naphthoate in 50g of chloroform, then add to 500g of 5wt% polyacrylamide aqueous solution, and emulsify at a high speed of 10000rpm for 15min to obtain a stable oil-in-water emulsion Finally, the emulsion droplet was measured to be 0.5-5 microns by optical microscope observation, and the above-mentioned oil-in-water emulsion was transferred to a three-necked flask, and the pH of the emulsion was adjusted to 6, and the temperature was set to 30°C. Weigh 100g of phenolic resin prepolymer solution and add it dropwise into the homogeneous emulsion while stirring at a speed of 1000rpm. After dropping, the temperature is raised to 60°C and kept for 120min to obtain a suspension of micro-nanocapsules with liquid capsule cores. The suspension was suction filtered and washed to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com