Wear-resistant high-chromium cast iron centrifugal composite roll and production process for narrow strip steel two-high mill

A high-chromium cast iron, two-roll mill technology, applied in the direction of rolls, manufacturing tools, metal rolling, etc., to achieve the effects of excellent use, reduced production costs, and significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The specification of the composite roll in this embodiment is Φ580*480, the roll number is 16L1665, and the structure is a three-layer centrifugal composite structure. The chemical composition and mass percentage of the material are shown in Table 1, Table 2 and Table 3.

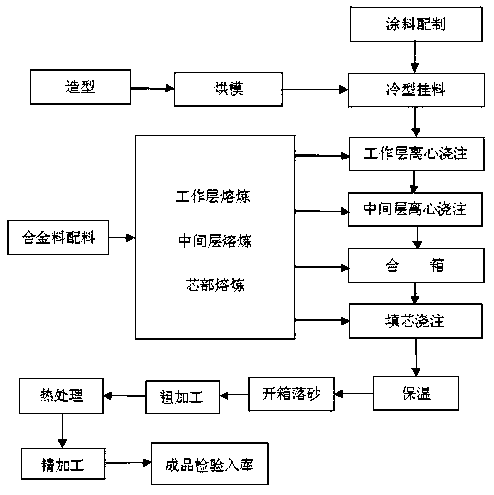

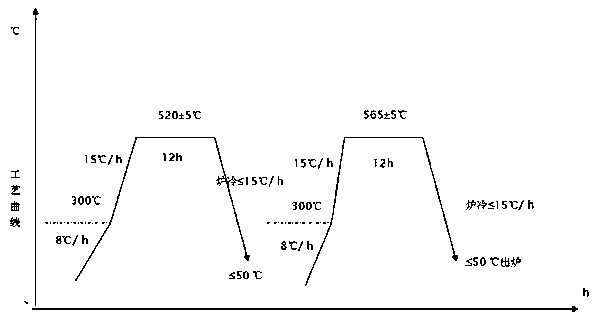

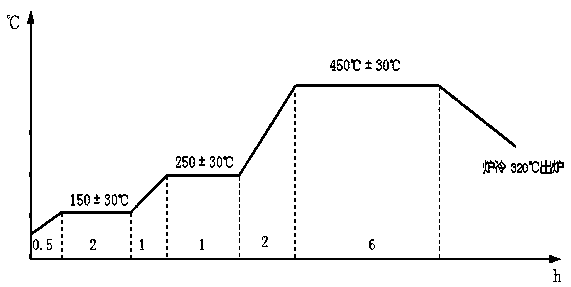

[0047] The production process of the composite roll of the present embodiment includes the processes of molten iron metamorphism, centrifugal casting, and heat treatment, and the specific process steps are as follows:

[0048] (1) Hot metal deterioration treatment process: 1.5t, 1t, 3t intermediate frequency induction furnaces are used to smelt the molten iron in the working layer, the middle layer and the core; after the molten iron in the working layer is cleared, 10kg / t of broken glass is added to the liquid surface to protect the molten iron from oxidation 15min before tapping, add ferrovanadium with 0.5% molten iron content in the furnace with a particle size of 10mm, add 0.2% ferromanganese part...

Embodiment 2

[0053] The specification of the composite roll in this embodiment is Φ580*480, the roll number is 16L1703, and the structure is a three-layer centrifugal composite structure. The chemical composition and mass percentage of the material are shown in Table 1, Table 2 and Table 3.

[0054] The production process of the composite roll of the present embodiment includes the processes of molten iron metamorphism, centrifugal casting, and heat treatment, and the specific process steps are as follows:

[0055] (1) Hot metal deterioration treatment process: 1.5t, 1t, 3t intermediate frequency induction furnaces are used to smelt the molten iron in the working layer, the middle layer and the core; after the molten iron in the working layer is cleared, 10kg / t of broken glass is added to the liquid surface to protect the molten iron from oxidation 15min before tapping, add 0.5% molten iron vanadium with a particle size of 20mm in the furnace, add 0.2% ferromanganese particles with a parti...

Embodiment 3

[0060] The specification of the composite roll in this embodiment is Φ580*480, the roll number is 16L1732, and the structure is a three-layer centrifugal composite structure. The chemical composition and mass percentage of the material are shown in Table 1, Table 2 and Table 3.

[0061] The production process of the composite roll of the present embodiment includes the processes of molten iron metamorphism, centrifugal casting, and heat treatment, and the specific process steps are as follows:

[0062] (1) Hot metal deterioration treatment process: 1.5t, 1t, 3t intermediate frequency induction furnaces are used to smelt the molten iron in the working layer, the middle layer and the core; after the molten iron in the working layer is cleared, 10kg / t of broken glass is added to the liquid surface to protect the molten iron from oxidation 15min before tapping, add 0.5% molten iron vanadium with a particle size of 12mm, add 0.2% ferromanganese particles with a particle size of 7mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com