Method for manufacturing building sheet material by utilizing solid wastes

A technology for building boards and solid waste, applied in the field of building materials, can solve the problems of insufficient consumption capacity and secondary utilization, and achieve the effects of saving resources, good heat insulation effect, and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

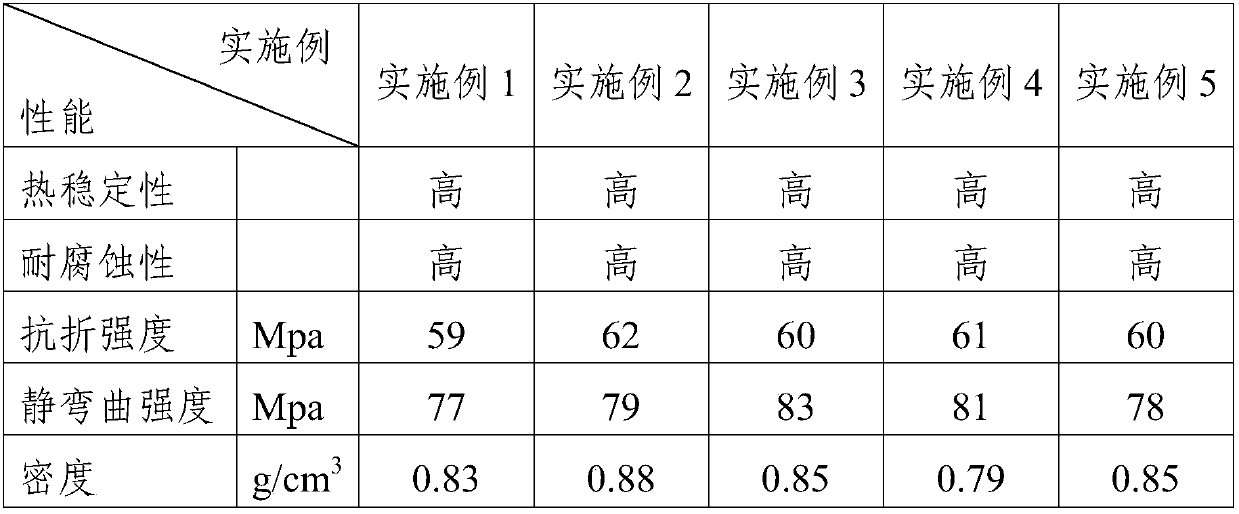

Examples

Embodiment 1

[0030] A method of making building boards from solid waste, the method comprising the steps of:

[0031] (1) Modification of red mud: mix red mud and phosphogypsum at a weight ratio of 2:1, add water and stir for 1 hour, filter to remove water, and dry the obtained mixture naturally, bake at 800°C for 2 hours, and cool to obtain Modified red mud. After the modified red mud is crushed, ground and screened at high speed, the modified red mud powder with a mesh number of 150-200 mesh can be obtained;

[0032] (2) Add crop straw, ammonium persulfate, and calcium hydroxide to boiling water and cook for 8 hours, remove and drain, dry naturally until the water content is ≤15%, and then finely grind with a fine mill to obtain plant fiber powder;

[0033] (3) Add modified red mud powder, plant fiber powder, Portland cement, fly ash, montmorillonite, zinc borate, and calcium lignosulfonate to the reaction kettle in sequence, control the stirring temperature to 70°C, and stir for 1 hour ...

Embodiment 2

[0037] A method of making building boards from solid waste, the method comprising the steps of:

[0038] (1) Modification of red mud: mix red mud and phosphogypsum at a weight ratio of 2:1, add water and stir for 1 hour, filter to remove water, dry the obtained mixture naturally, bake at 850°C for 2 hours, and cool to obtain Modified red mud. After the modified red mud is crushed, ground and screened at high speed, the modified red mud powder with a mesh number of 150-200 mesh can be obtained;

[0039] (2) Add crop straw, ammonium persulfate, and calcium hydroxide to boiling water and boil for 10 hours, remove and drain, dry naturally until the water content is ≤15%, and then finely grind with a fine mill to obtain plant fiber powder;

[0040] (3) Add modified red mud powder, plant fiber powder, Portland cement, fly ash, montmorillonite, zinc borate, and sodium lignosulfonate to the reaction kettle in sequence, control the stirring temperature to 70°C, and stir for 1 hour Fin...

Embodiment 3

[0044] A method of making building boards from solid waste, the method comprising the steps of:

[0045] (1) Modification of red mud: mix red mud and phosphogypsum at a weight ratio of 2:1, add water and stir for 1 hour, filter to remove water, and dry the obtained mixture naturally, bake at 750°C for 2 hours, and cool to obtain Modified red mud. After the modified red mud is crushed, ground and screened at high speed, the modified red mud powder with a mesh number of 150-200 mesh can be obtained;

[0046] (2) Add crop straw, ammonium persulfate and calcium hydroxide to boiling water and cook for 5 hours, remove and drain, dry naturally until the water content is ≤15%, and then finely grind with a fine mill to obtain plant fiber powder;

[0047] (3) Add modified red mud powder, plant fiber powder, Portland cement, fly ash, montmorillonite, zinc borate, and magnesium lignosulfonate to the reaction kettle in sequence, control the stirring temperature to 70°C, and stir for 1 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com