Pressure regulator and fuel supply device

A pressure regulator and fuel technology, which is applied to fuel injection devices, low-pressure fuel injection, liquid fuel feeders, etc., can solve the problems of difficulty in changing fuel pressure as soon as possible, hindering responsiveness and pressure regulation accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

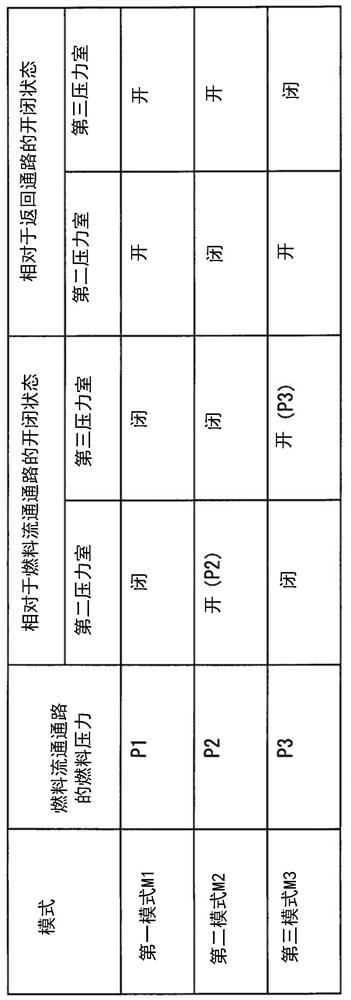

no. 1 approach

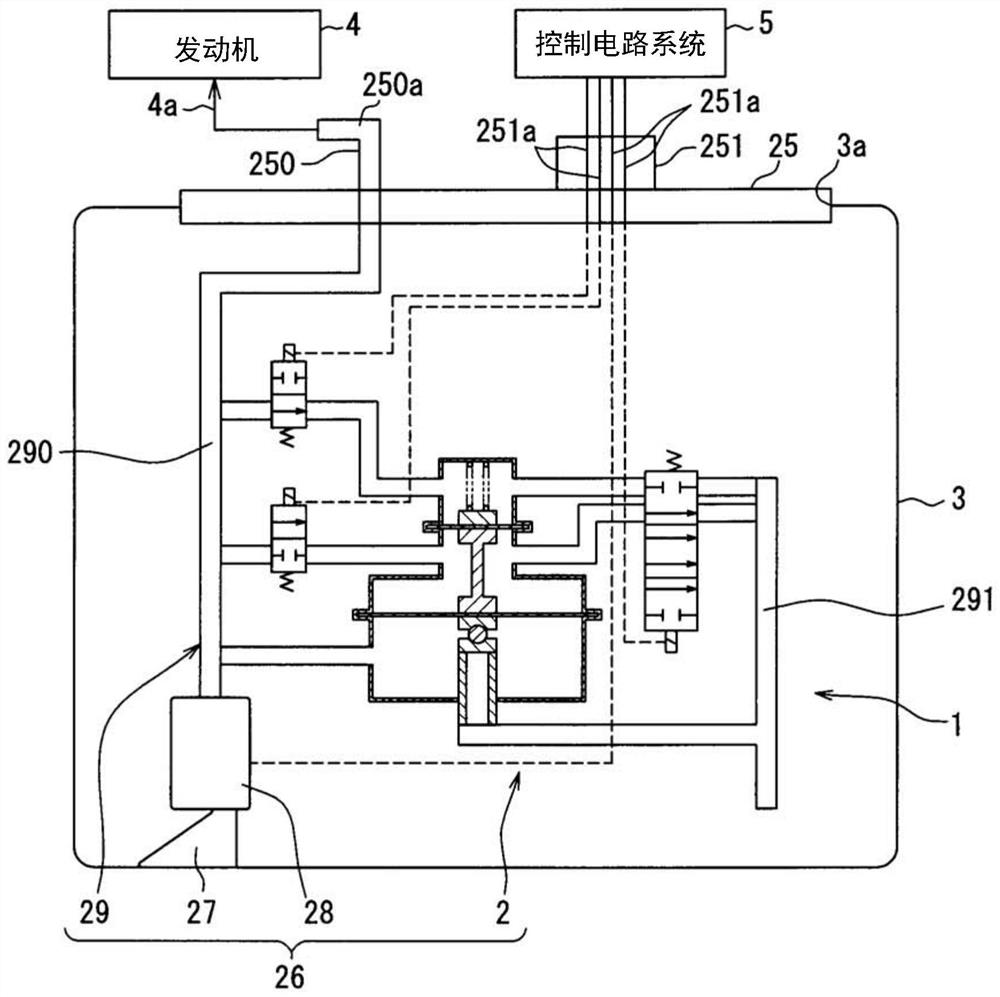

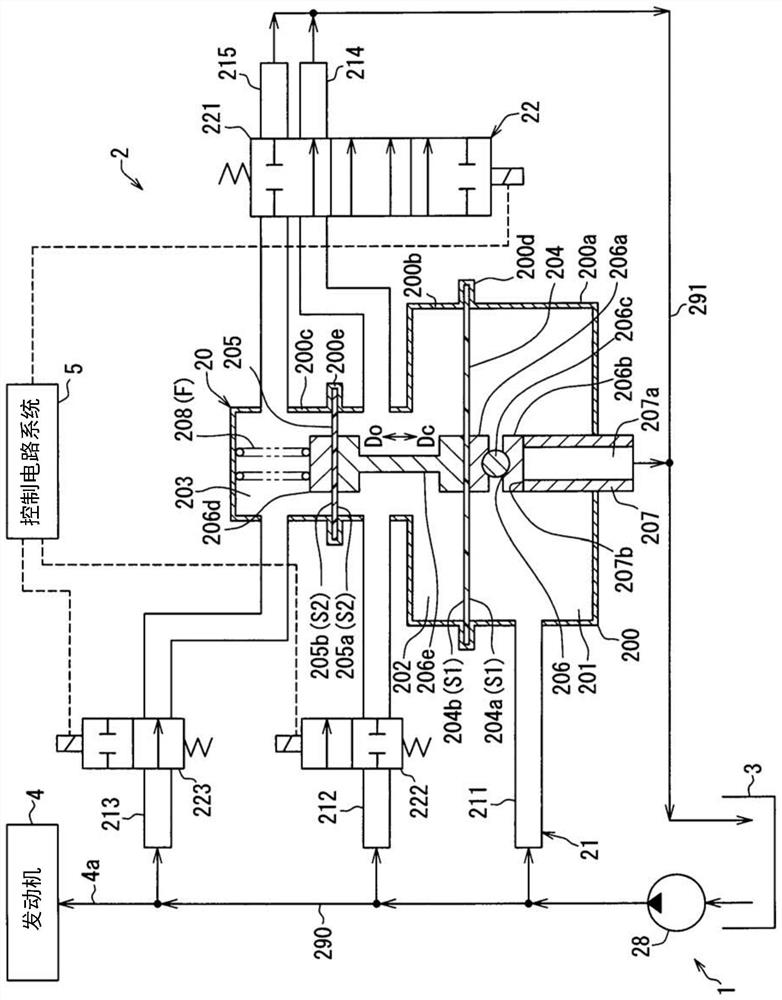

[0043] Such as figure 1 As shown, the fuel supply device 1 having the pressure regulator 2 according to the first embodiment of the present invention is applied to an internal combustion engine 4 of a vehicle by being mounted on a fuel tank 3 . The fuel supply device 1 supplies fuel stored in a fuel tank 3 in a vehicle to an internal combustion engine 4 outside the fuel tank 3 . Here, the insertion hole 3 a penetrates the upper wall of the fuel tank 3 . The fuel supply device 1 is inserted into the fuel tank 3 through the insertion hole 3a. In such an inserted state, the internal combustion engine 4 to be supplied with fuel from the fuel supply device 1 may be a gasoline engine or a diesel engine.

[0044] The fuel supply device 1 has a cover body 25 and a pump unit 26 . The lid body 25 is attached to the upper wall of the fuel tank 3 . By attaching in this way, the cover body 25 closes the insertion hole 3a. The cover body 25 has an integral fuel supply pipe 250 and an e...

no. 2 approach

[0104] Such as Figure 7 As shown, the second embodiment of the present invention is a modified example of the first embodiment.

[0105] The passage unit 2021 of the voltage regulator 2002 of the second embodiment does not form the second branch passage 212 . And correspondingly, the third release passage 2215 of the passage unit 2021 shares a common portion 2216 on the third pressure chamber 203 side with respect to the switching unit 2022 which will be described in detail later with the third branch passage 2213 . In addition, about the passage unit 2021, other parts are the same as those described in the first embodiment.

[0106] The switching unit 2022 of the voltage regulator 2002 of the second embodiment is composed only of the third solenoid valve 2223 , and the third solenoid valve 2223 is electrically connected to the control circuit system 5 through the terminal 251 a of the electrical connector 251 . The third solenoid valve 2223 is a three-port directional swit...

no. 3 approach

[0120] Such as Figure 11 As shown, the third embodiment of the present invention is a modified example of the first embodiment.

[0121] The passage unit 3021 of the voltage regulator 3002 of the third embodiment does not form the third branch passage 213 . And correspondingly, the second release passage 3214 of the passage unit 3021 shares a common portion 3216 on the second pressure chamber 202 side with respect to the switching unit 3022 which will be described in detail later with the second branch passage 3212 . In addition, about the passage unit 3021, other parts are the same as those described in the first embodiment.

[0122] The switching unit 3022 of the voltage regulator 3002 of the third embodiment is composed only of the second solenoid valve 3222 , and the second solenoid valve 3222 is electrically connected to the control circuit system 5 through the terminal 251 a of the electrical connector 251 . The second solenoid valve 3222 is a three-port directional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com