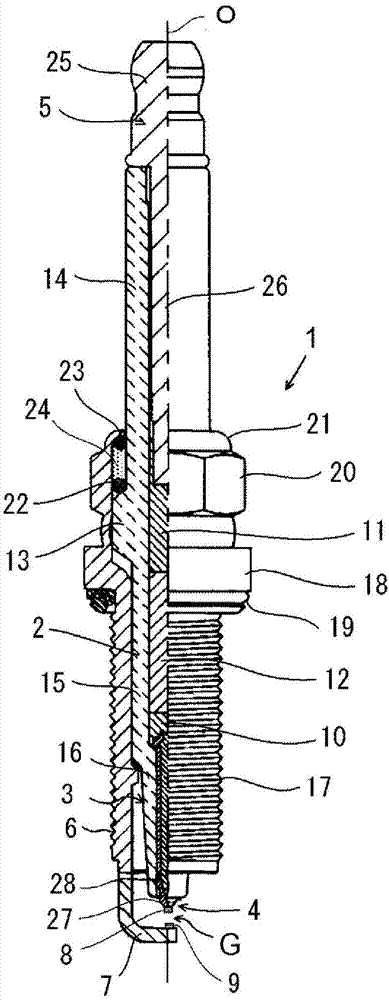

spark plug

A spark plug and tip technology, applied in the field of spark plugs, can solve problems such as spark consumption at the front end, achieve the effects of excellent durability, inhibit oxidation, and reduce the loss of oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] [Test No.1-27]

[0074]

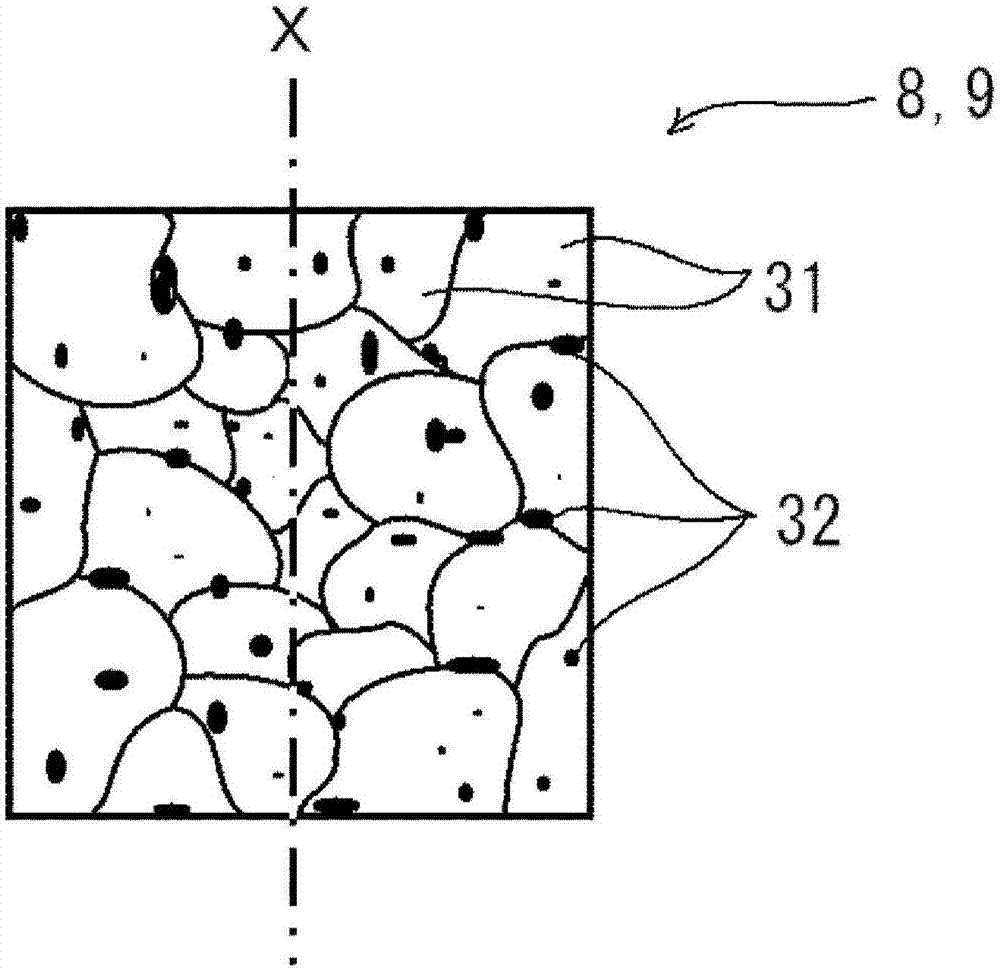

[0075] The tip is fabricated as follows. First, metal powder was mixed in the same mixing ratio as the metal base material shown in Table 1 and Table 2, and the green compact formed by mixing oxide powder in a predetermined ratio was degreased, and then vacuum Sintering is carried out in a neutral or non-oxidizing or reducing environment, thereby producing a cylindrical end with a relative density of more than 95%.

[0076] As described above, the center electrode and the ground electrode are prepared by preparing an alloy melt with a predetermined composition, performing wire drawing, etc., and making appropriate adjustments to form a predetermined shape and a predetermined size. A center electrode formed of a core made of a Cu alloy, and a ground electrode made of a Ni alloy.

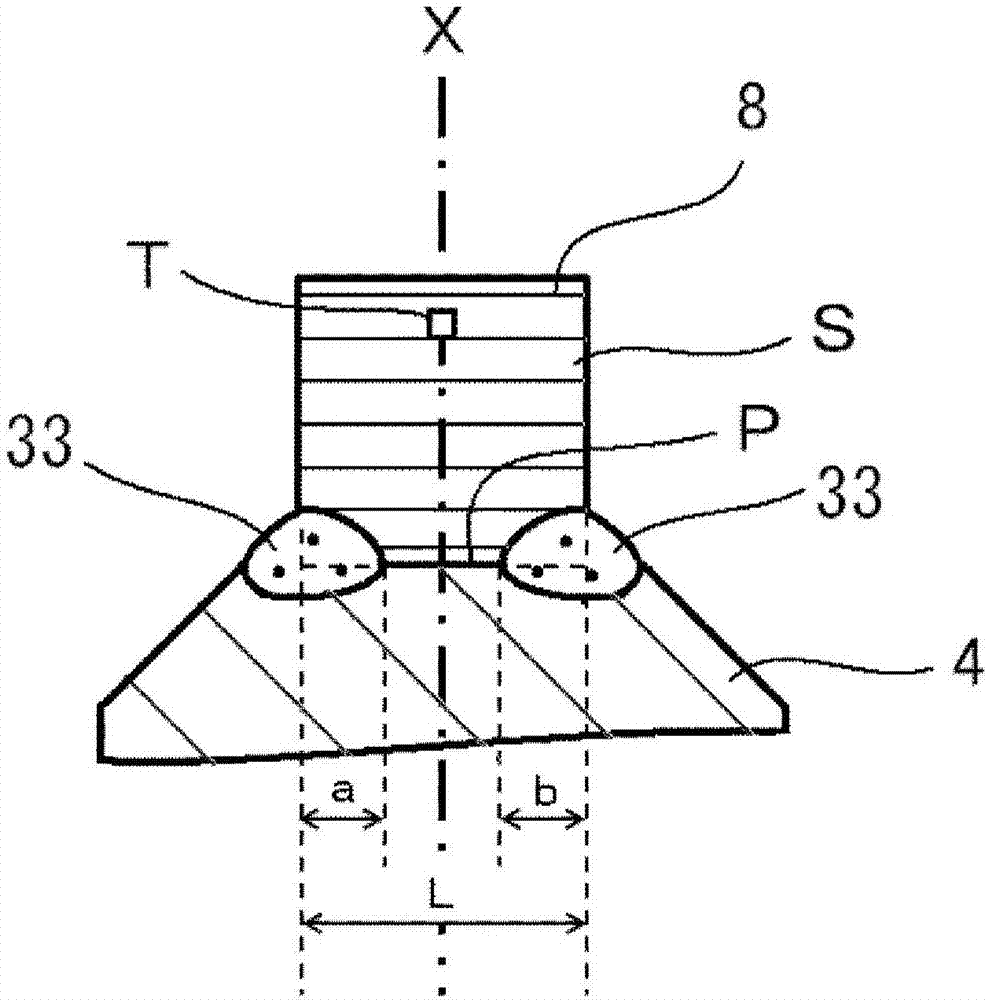

[0077] Next, the ground electrode is joined to one end surface of the metal shell, and the produced end is joined to the end of the ground electrode of the metal s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com