A stripping solution for preparing two-dimensional nanomaterials and its application

A two-dimensional nanomaterial and solution technology, applied in the fields of nanocarbon, nanotechnology, phosphorus preparation, etc., can solve the damage of graphene electronic structure and crystal integrity, limit application and industrialization development, process condition control conditions, etc. problem, to achieve the effect of easy industrial application, avoid secondary aggregation, avoid strong acid and strong corrosive chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, add 10ml of ethanol, 10ml of isobutanol, 15ml of tert-butanol, and 100ml of glycerol into 1L of deionized water; Methylpyrrolidone, 0.05g of 9-anthracene carboxylic acid, and 0.01g of pyrene-1-sulfonic acid sodium salt were added to the above aqueous solution, and after uniform stirring, the stripping solution was obtained.

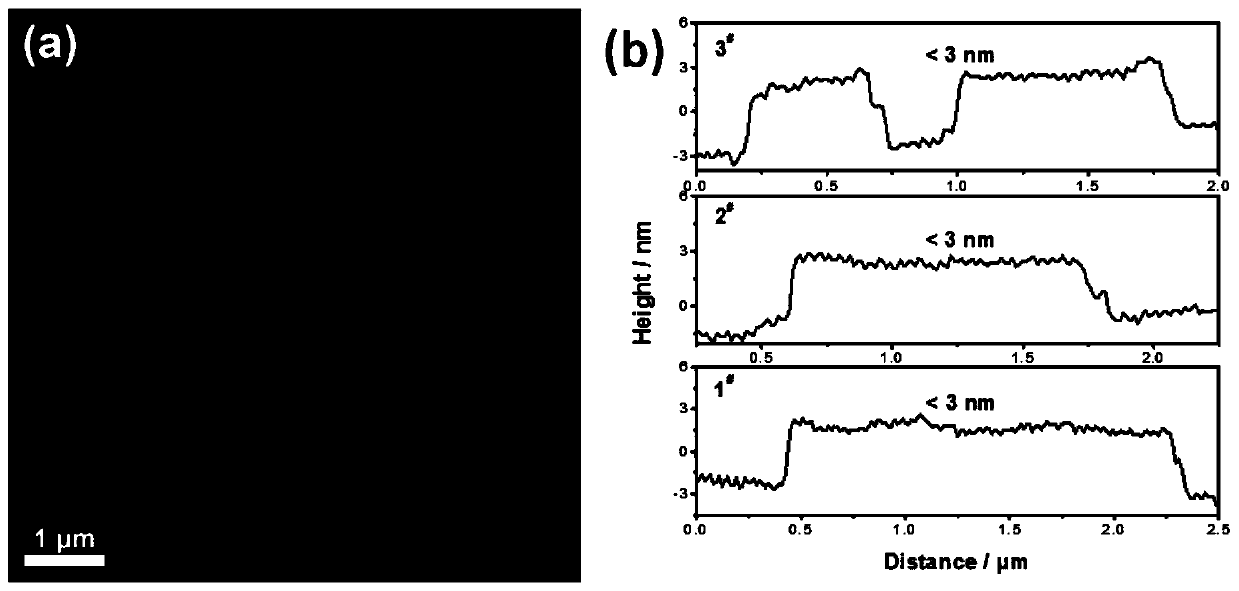

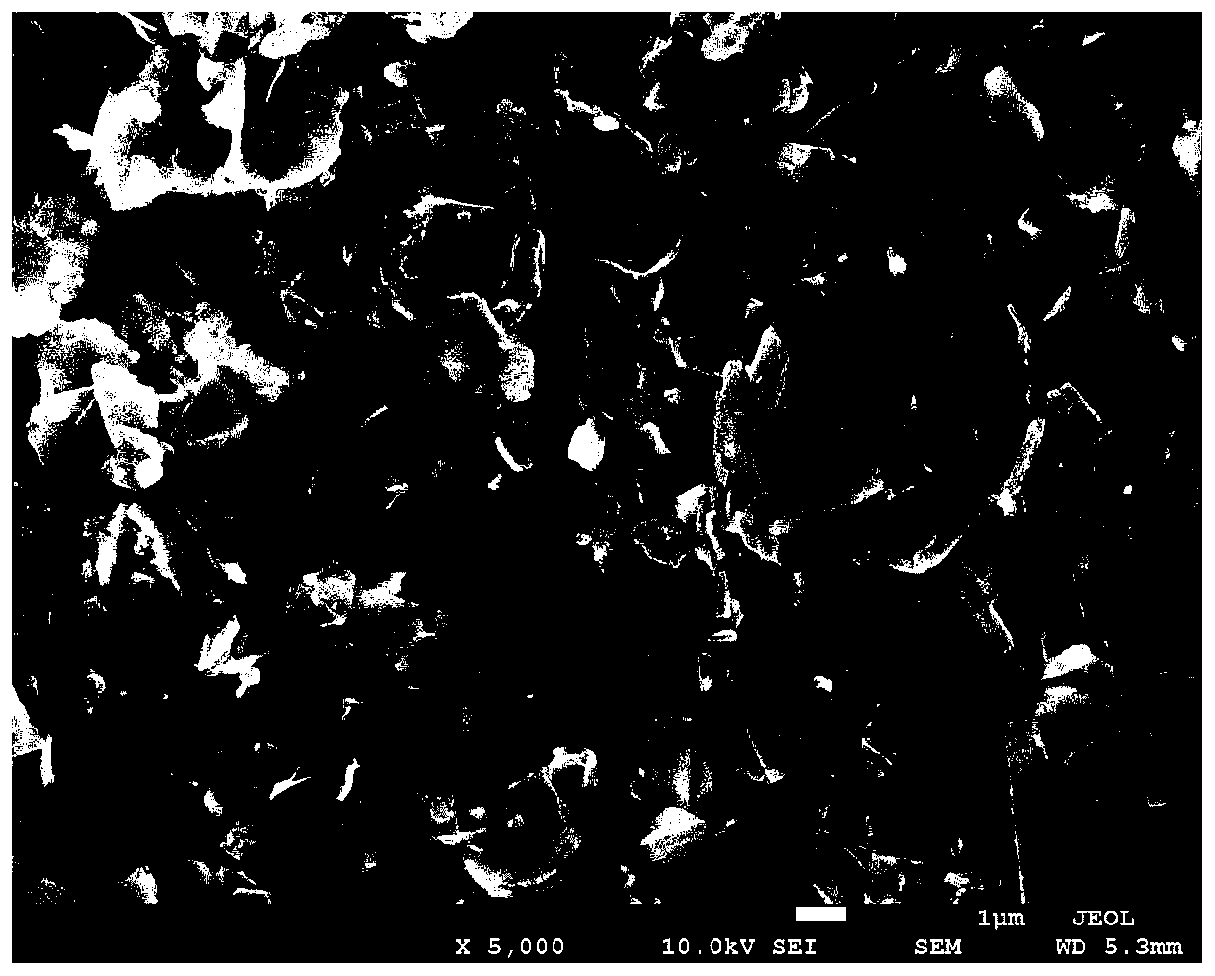

[0037] Stir and disperse 100g of flake graphite in the above solution. After mechanical shearing and ultrasonic stripping, graphene with a thickness of about 3nm and complete crystal structure can be obtained. The atomic force microscope and scanning electron microscope microscopic pictures are as follows: figure 1 , figure 2 shown.

[0038] Mechanical shearing and ultrasonic stripping are performed as follows:

[0039] (1) Submerge the cutter head of the emulsification cutting machine under the liquid surface, and cut the mixed solution for 2 hours under the condition of 40°C water bath, keeping the cutter head rotation speed at 8000rpm....

Embodiment 2

[0056] First, add 10ml of ethanol, 100ml of isopropanol, 10ml of n-butanol, 50ml of tert-butanol, and 20ml of glycerol into 1L of deionized water; Add sulfoxide, 0.3ml nitrogen-methylpyrrolidone, 0.02g 9-anthracene carboxylic acid, and 0.05g pyrene-1-sulfonic acid sodium salt into the above-mentioned aqueous solution, and stir to obtain a peeling solution. 100g molybdenum disulfide The powder is stirred and dispersed in the above solution, and after mechanical shearing and ultrasonic stripping, molybdenum disulfide nanosheets with a thickness of 1-10 nm and good crystallinity can be obtained. Compared with pure aqueous solution, molybdenum disulfide prepared by this solution The yield of nanosheets was increased by about 2 times.

Embodiment 3

[0058] First, add 10ml of ethanol, 10ml of n-propanol, 20ml of isopropanol, 15ml of tert-butanol, and 100ml of sec-butanol into 1L of deionized water; Dimethyl formamide, 1ml dimethyl sulfoxide, 0.1g 9-anthracene carboxylic acid, 0.06g pyrene-1-sulfonic acid sodium salt were added to the above aqueous solution, and after stirring evenly, the peeling solution was obtained. 30g black phosphorus powder Stirring and dispersing in the above solution, after mechanical shearing and ultrasonic stripping, black phosphorus nanosheets with a thickness of 1-10 nm can be obtained. Compared with pure aqueous solution, the yield of black phosphorus nanosheets prepared by this solution is increased by about 3 times.

[0059] In the peeling solution developed by the present invention, and under the composite action of mechanical shear and ultrasound, the layered solid powder can be efficiently and cleanly peeled into two-dimensional nano-sheets, such as graphene, molybdenum disulfide, black ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com