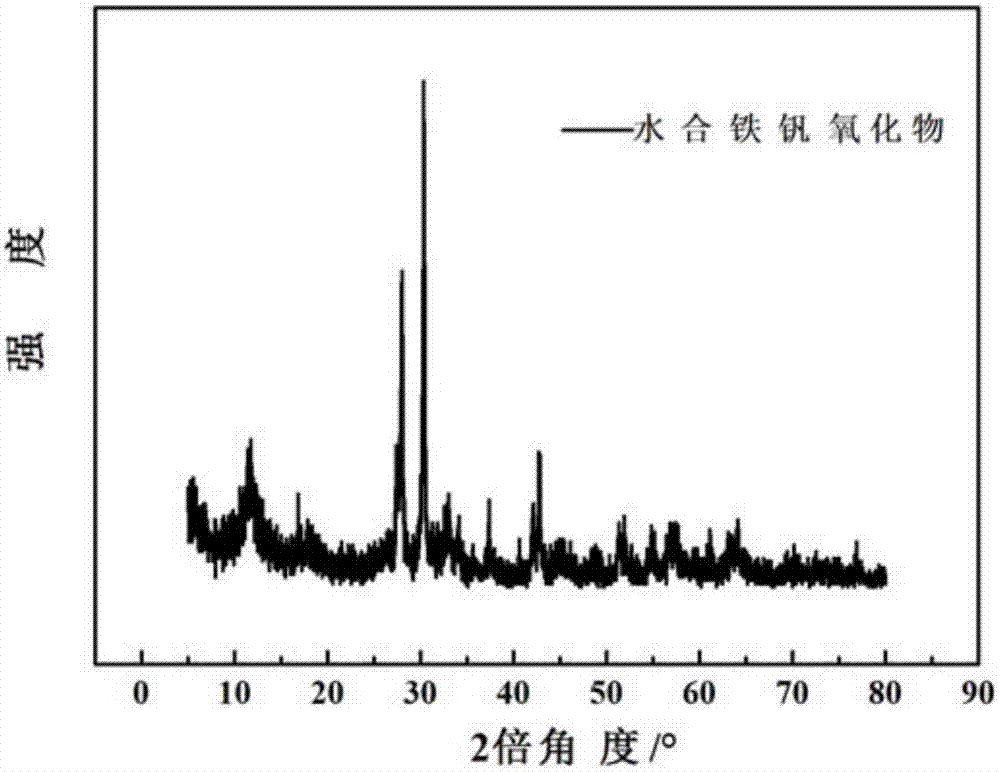

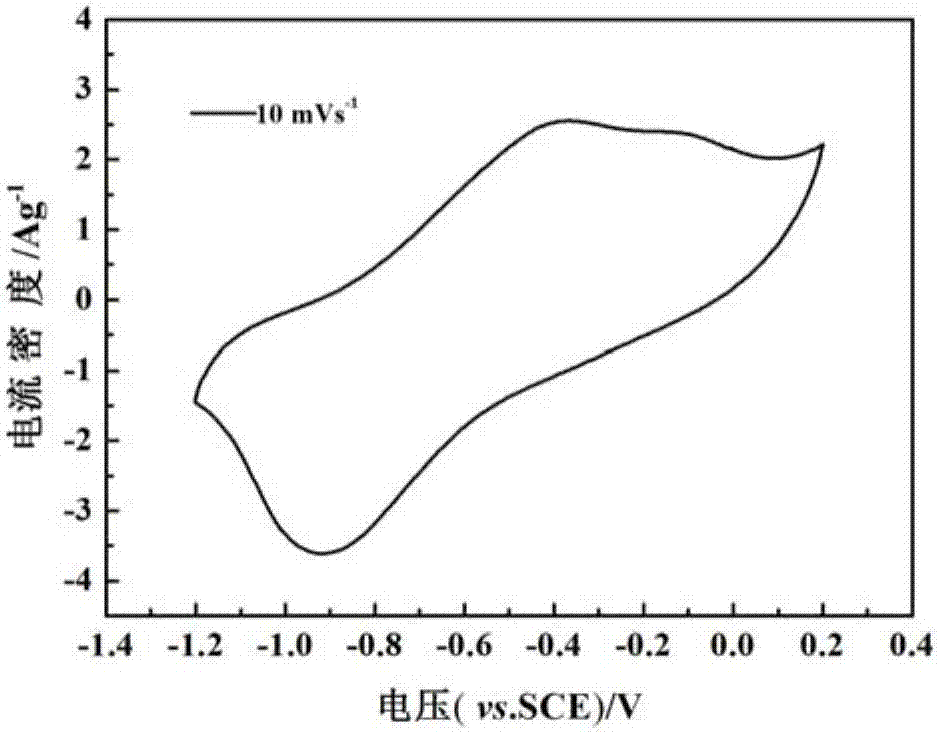

Preparation and application methods of hydrous ferrovanadium oxide as aqueous magnesium ion battery cathode material

A magnesium-ion battery and negative electrode material technology, applied in battery electrodes, chemical instruments and methods, secondary batteries, etc., can solve the problems of limited research on negative electrode materials, difficulty in large-scale production, poor battery cycle performance, etc., and achieve low cost , Good for large-scale production and application, low intercalation potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dissolve 1 mmol of ferric nitrate in 15 mL of water, and stir at room temperature for 20 min;

[0031] (2) Dissolve 1 mmol of ammonium metavanadate in 15 mL of water, and stir for 30 min at 70° C.;

[0032] (3) Add the ammonium metavanadate solution dropwise to the iron salt solution, and stir the resulting mixture at room temperature for 2 h;

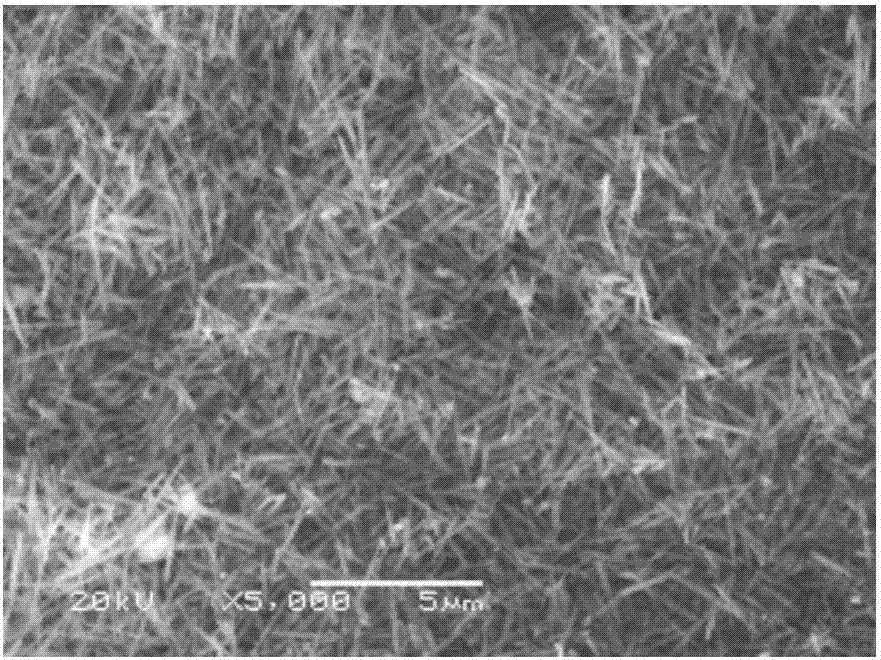

[0033] (4) Transfer the above mixed solution to a reaction kettle for hydrothermal reaction at 150° C. for 6 hours, and filter, wash and dry the precipitate to obtain linear hydrated iron vanadium oxide.

[0034] It can be seen from the topography diagram that the particle size of linear hydrated iron vanadium oxide is small and evenly distributed, and Example 1 is the optimal synthesis condition.

Embodiment 2

[0036] Ferric nitrate in the embodiment 1 step (1) is changed into ferric chloride, ferric sulfate, ferric acetate. The rest of the synthesis conditions remain unchanged.

Embodiment 3

[0038] Change the hydrothermal temperature in step (2) of Example 1 to 60°C, 80°C, and 90°C. The rest of the synthesis conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com