Ferric oxyhydroxide material modified by metal-doped cyclodextrin and one-step synthesis method of ferric oxyhydroxide material

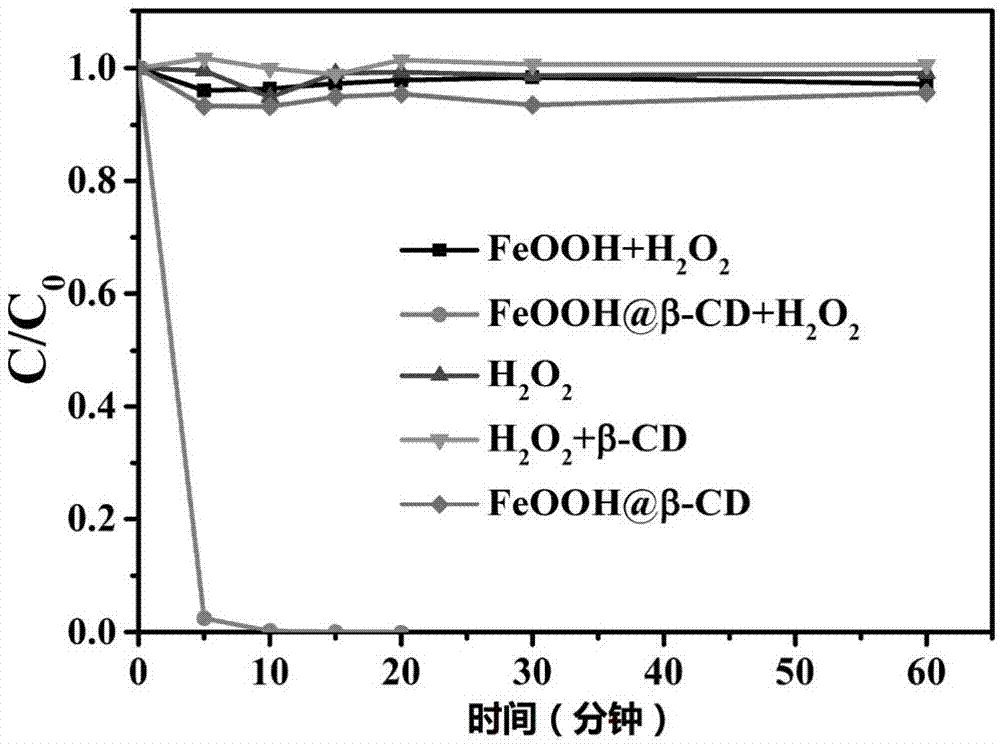

An iron oxyhydroxide, metal doping technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problem of long reaction time, poor regeneration and high energy consumption and other problems, to achieve the effect of improving catalytic degradation performance, improving material stability, and improving catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A one-step synthesis method of metal-doped cyclodextrin-modified iron oxyhydroxide materials, the steps are as follows:

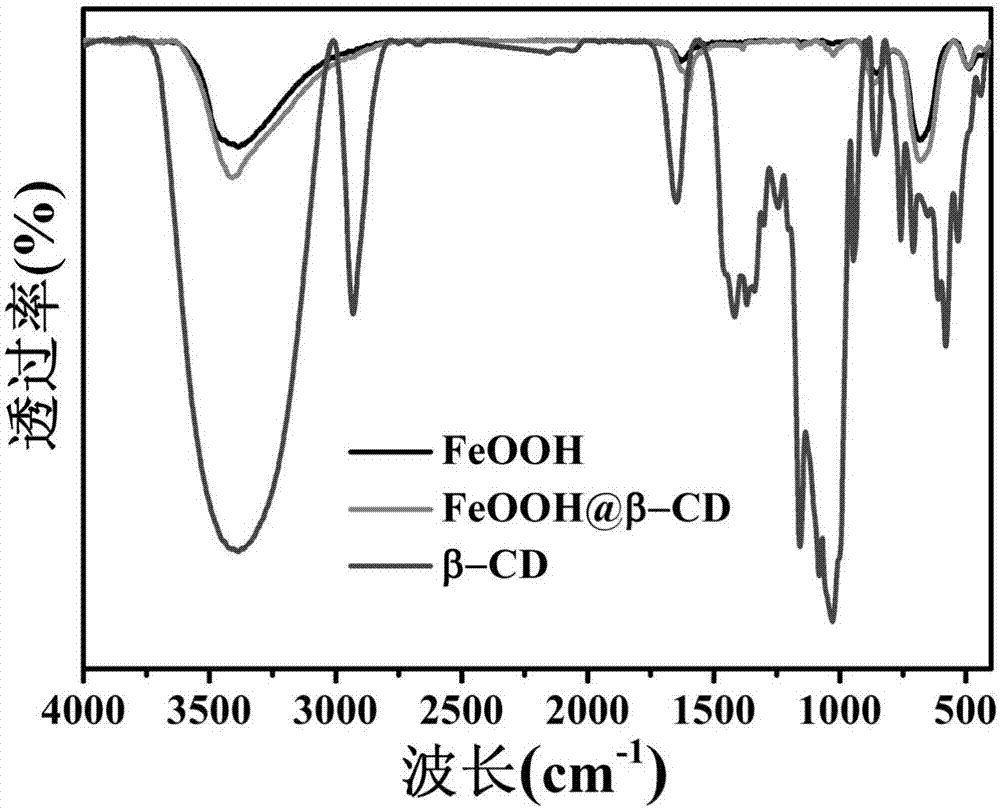

[0041] Weigh 10 to 100 grams of ferrous chloride, 5 to 20 grams of β-cyclodextrin, and copper nitrate in a conical flask, pour 250 mL of water into it, dissolve with ultrasonic waves, stir in a water bath at 25°C, and react for 30 hours. The obtained solid is washed with absolute ethanol and deionized water respectively, and dried to obtain a metal-doped cyclodextrin-modified iron oxyhydroxide material, which is a composite material of cyclodextrin-coated iron oxyhydroxide and copper ions.

Embodiment 2

[0043] With the one-step synthetic method described in embodiment 1, difference is: replace ferrous chloride with ferric chloride.

Embodiment 3

[0045]It is the same as the one-step synthesis method described in Example 1, except that cobalt nitrate is used instead of copper nitrate to obtain a composite material of iron oxyhydroxide and cobalt ions coated with cyclodextrin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com