Novel multi-stage pore carbon material and preparation method thereof

A carbon material and multi-level porous technology, applied in the field of novel hierarchical porous carbon materials and their preparation, can solve problems such as long preparation route, and achieve the effects of low equipment requirements, simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

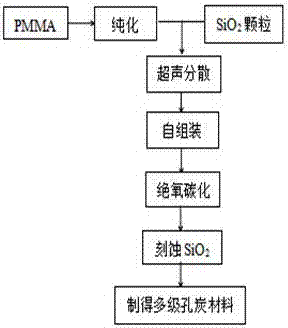

[0030] Specific embodiment 1 of the present invention: a kind of novel hierarchical porous carbon material, such as figure 1 As shown, it is prepared by the following method: polymethyl methacrylate (PMMA) is used as a macroporous template, and silicon dioxide is used as a mesoporous template; after self-assembly, carbonization, and removal of the template, it is obtained; the details include the following step:

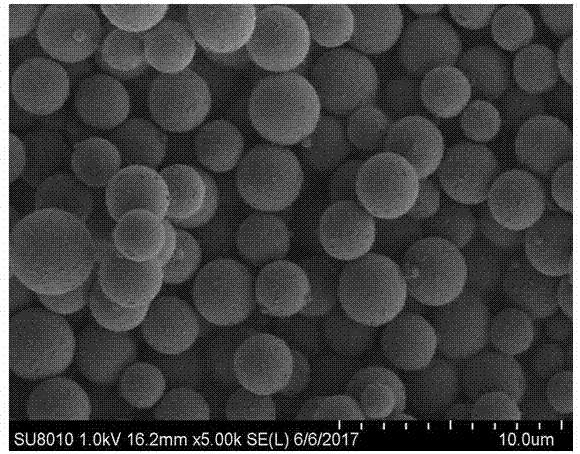

[0031] (1) Ultrasonicate PMMA in water for 10 minutes, pour it into a centrifuge tube, centrifuge at 1000 rpm for about 2 minutes, then dry it in an oven, and then grind it for use. The scanning electron microscope (SEM) picture is as follows figure 2 shown, from figure 2 It can be seen that after PMMA treatment, the particle size is uniform, the particle size is about 1-2 μm, and it is regular and orderly.

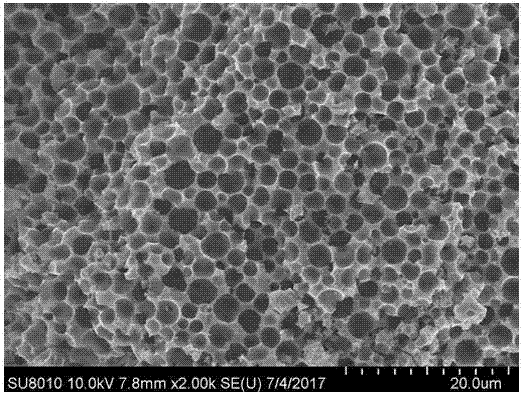

[0032] (2) Weigh 1gPMMA and 4mLSiO 2 Mix the dispersion, add 100mL of pure water, stir for about 1 hour, sonicate for about 4 hours, pour it into a petri d...

Embodiment 2

[0035] Example 2: A new type of hierarchical porous carbon material, using polymethyl methacrylate (PMMA) as a macroporous template, and silica as a mesoporous template; after self-assembly, carbonization, and removal of the template, it is obtained; Specifically include the following steps:

[0036] (1) Ultrasonicate PMMA particles in water for about 10 minutes, pour them into a centrifuge tube, centrifuge at 1000 rpm for about 2 minutes, then dry them in an oven, and then grind them for use.

[0037] (2) Weigh 0.5g PMMA particles and 2mL SiO 2 Mix the dispersion, add 100 mL of pure water, stir for about 1 h, sonicate for about 4 h, pour into a petri dish, and dry in an oven at 60°C to obtain an assembled solid block.

[0038] (3) in N 2 The carbonization was carried out in a muffle furnace under the atmosphere, the carbonization heating rate was 1 °C / min, the temperature was raised to 600 °C, the temperature was kept constant for 1 h, and cooled to room temperature under t...

Embodiment 3

[0040] Example 3: A new type of hierarchical porous carbon material, using polymethyl methacrylate (PMMA) as a macroporous template, and silica as a mesoporous template; after self-assembly, carbonization, and removal of the template, it is obtained; Specifically include the following steps:

[0041] (1) Ultrasonicate PMMA particles in water for about 10 minutes, pour them into a centrifuge tube, centrifuge at 1000 rpm for about 2 minutes, then dry them in an oven, and then grind them for use.

[0042] (2) Weigh 0.5g PMMA particles and 2mL SiO 2 Mix the dispersion, add 100 mL of pure water, stir for about 1 h, sonicate for about 4 h, pour into a petri dish, and dry in an oven at 60°C to obtain an assembled solid block.

[0043] (3) in N 2 The carbonization was carried out in a muffle furnace under the atmosphere, the carbonization heating rate was 1°C / min, the temperature was raised to 500°C, kept at a constant temperature for 2h, and cooled to room temperature under the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com