Slide plate brick for slag stopping of converter, and production method thereof

A converter slag blocking and sliding brick technology, applied in the field of iron and steel smelting, can solve problems such as poor thermal shock performance, comprehensive performance needs to be improved, and low cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

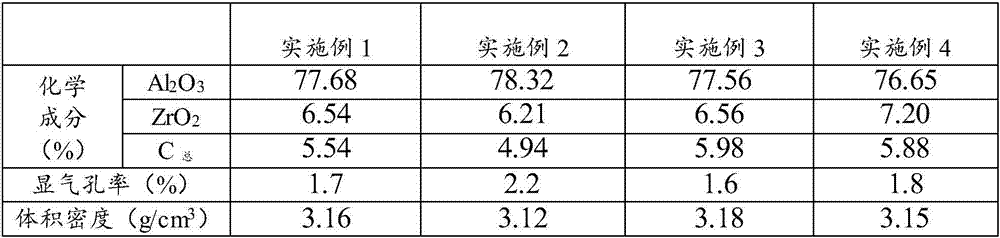

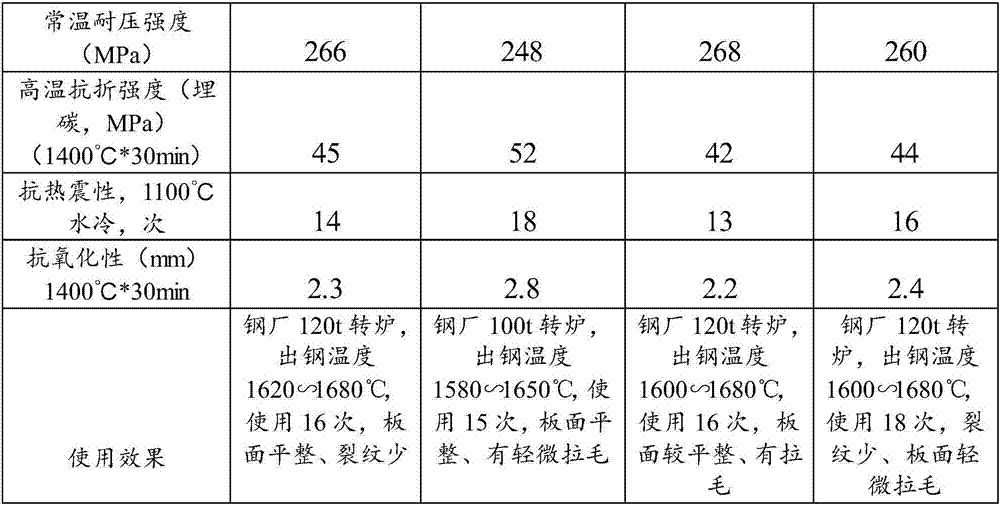

Examples

preparation example Construction

[0051]The raw material for the preparation of the sliding brick for converter slag blocking provided by the present invention includes 45%-60% of tabular alumina, preferably 48%-57%, more preferably 45%-54%. In the present invention, the tabular alumina includes tabular alumina particles and tabular alumina fine powder. Wherein, the platy corundum particles are selected from 2-1 mm platy corundum, 1-0.5 mm platy corundum and 0.5-0 mm platy corundum, and the platy corundum fine powder is selected from 325 mesh platy corundum fine powder.

[0052] The raw material for the preparation of the sliding brick for converter slag blocking provided by the present invention also includes 10% to 30% zircon mullite, preferably 15% to 25%, more preferably 18% to 22%. Preferably, the zircon-mullite is selected from 2-1 mm zircon-mullite and 1-0 mm zircon-mullite.

[0053] In the present invention, the platy corundum and zirconium-mullite aggregates are the basic guarantees for high-quality ...

Embodiment 1

[0095] 13 parts of 325 mesh tabular corundum fine powder, 10 parts of 2.5 μm bimodal α-alumina micro powder, 2 parts of 200 mesh industrial aluminum flakes, 5 parts of 325 mesh industrial aluminum powder, 2 parts of 325 mesh clay, 2 parts of micron carbon black Put it into the premixing equipment together with 1 part of 325 mesh boron carbide, and premix for 20 minutes to prepare premixed powder. 15 parts of 2~1mm tabular alumina, 11 parts of 1~0.5mm tabular alumina, 13 parts of 0.5~0mm tabular alumina, 10 parts of 2~1mm zircon mullite, 10 parts of 1~0mm zircon mullite, 5 Put 1-0mm silicon carbide into the kneader and dry mix for 3 minutes, add 1.6 parts of MS-1 silicone resin and 2.24 parts of PF5321 phenolic resin and mix for 12 minutes, then add premixed powder and mix for 5 minutes, then add 0.4 parts of MS-1 silicone resin and 0.56 parts of PF5321 phenolic resin were mixed and milled for 3 minutes, and finally 1 part of aluminum fiber was evenly sprinkled in, and the mate...

Embodiment 2

[0097] 12 parts of 325 mesh tabular corundum fine powder, 10 parts of 2.5μm bimodal α-alumina micropowder, 2.5 parts of 200 mesh industrial aluminum flakes, 5.5 parts of 325 mesh industrial aluminum powder, 1.5 parts of 325 mesh clay, 1.5 parts of micron carbon black Add 0.5 parts of 325-mesh boron carbide into the pre-mixing equipment, and pre-mix for 15 minutes to prepare pre-mixed powder. 16 parts of 2-1mm tabular alumina, 10 parts of 1-0.5mm tabular alumina, 14 parts of 0.5-0mm tabular alumina, 9 parts of 2-1mm zircon mullite, 10 parts of 1-0mm zircon mullite, 6 Put 1~0mm silicon carbide into the kneader and dry mix for 2 minutes, add 1.65 parts of MS-1 silicone resin and 1.8 parts of PF5321 phenolic resin and mix for 10 minutes, then add premixed powder and mix for 4 minutes, then add Mix and grind 0.55 parts of MS-1 silicone resin and 0.6 parts of PF5321 phenolic resin for 2 minutes, and finally sprinkle 1.5 parts of aluminum fiber evenly, and discharge after 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com