A method for treating waste mud and cuttings of deep well sulfonated drilling fluid

A technology for drilling waste mud and polysulfonic acid, which is applied in separation methods, wellbore/well components, pyrolysis treatment of sludge, etc., can solve the problems of high treatment efficiency and small footprint, and achieves enhanced heat transfer efficiency and reduced Thermal pollution, the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

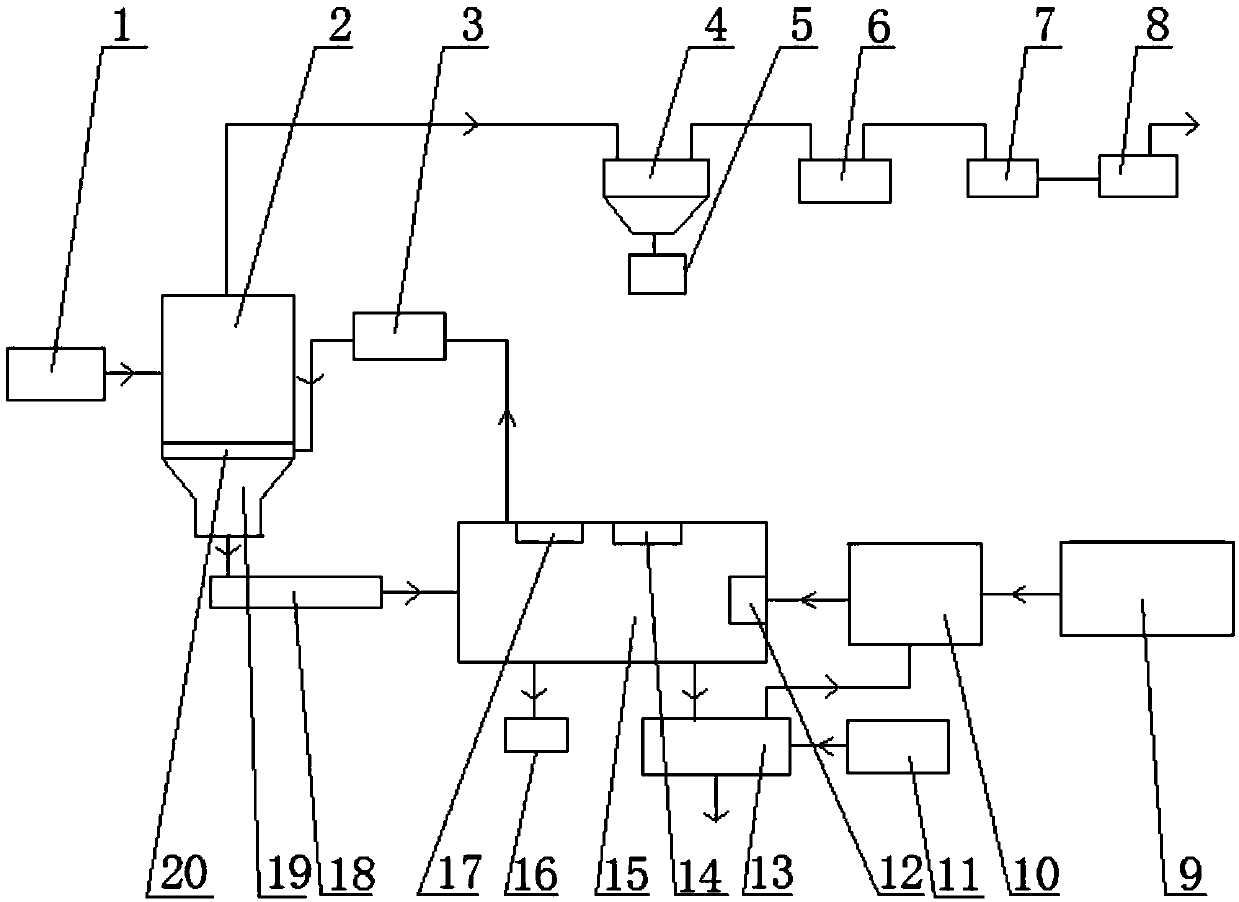

[0026] like figure 1As shown, the deep well polysulfide drilling fluid waste mud and drill cuttings containing sulfonated phenolic resin, asphalt powder, barite and water content of more than 85% are conveyed from the upper part of the cooling heat exchange drying furnace 2 by the feeder 1 into the cooling heat exchange drying furnace 2, and start the stirring device in the cooling heat exchange drying furnace 2. The high-heat gas with a temperature of 850-1100°C comes from the high-temperature pyrolysis furnace 15 and is burned by the secondary burner 3. After being evenly distributed by the gas distributor 20 at the lower part of the cooling heat-exchanging drying furnace 2, it enters the cooling heat-exchanging drying furnace 2 within. The waste mud and drill cuttings entering the cooling heat exchange drying furnace 2 fully contact with the high-heat gas entering the cooling heat exchange drying furnace 2 in reverse, and the waste mud and drill cuttings are preheated to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com