Laser preparation method of titanium-nitride-coating-contained textured surface of titanium alloy

A titanium alloy and texturing technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the gap in wear resistance of composite coatings, limited wear resistance, and the degree of improvement in material surface hardness. Large and other problems, to achieve the effect of improving surface wear resistance, improving corrosion resistance, enhancing surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

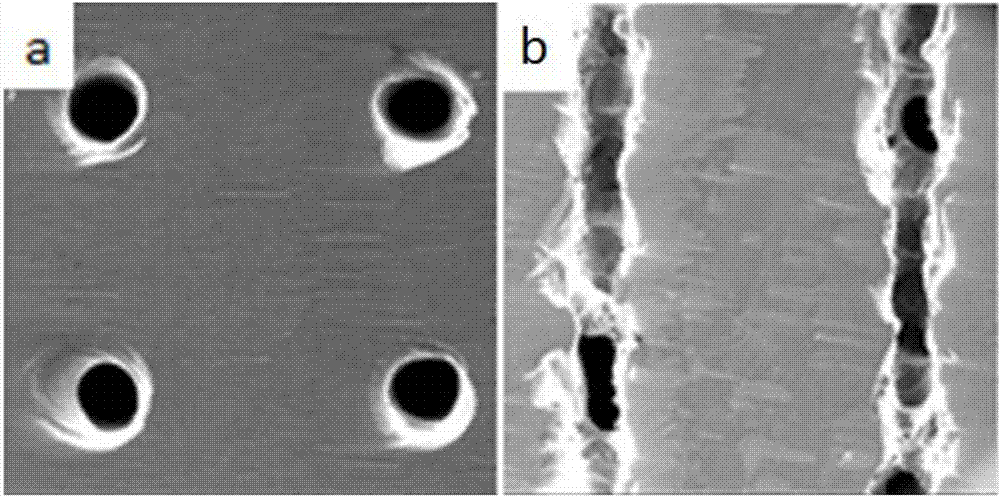

[0044] 1. The Ti-35Nb-7Zr-5Ta biomedical titanium alloy sample with a size of 15×15×2mm was laser-prepared with a biomedical titanium alloy containing titanium nitride coating textured surface. The specific steps are as follows:

[0045] (1) First, the surface of the biomedical titanium alloy substrate is polished with sandpaper from 240#, 400#, 800#, 1200#, 1500#, 2000# in sequence, and mechanically polished, and then ultrasonically cleaned in absolute ethanol for 10 Minutes (ultrasonic frequency 40KHz), dry with a hair dryer with cold air for later use.

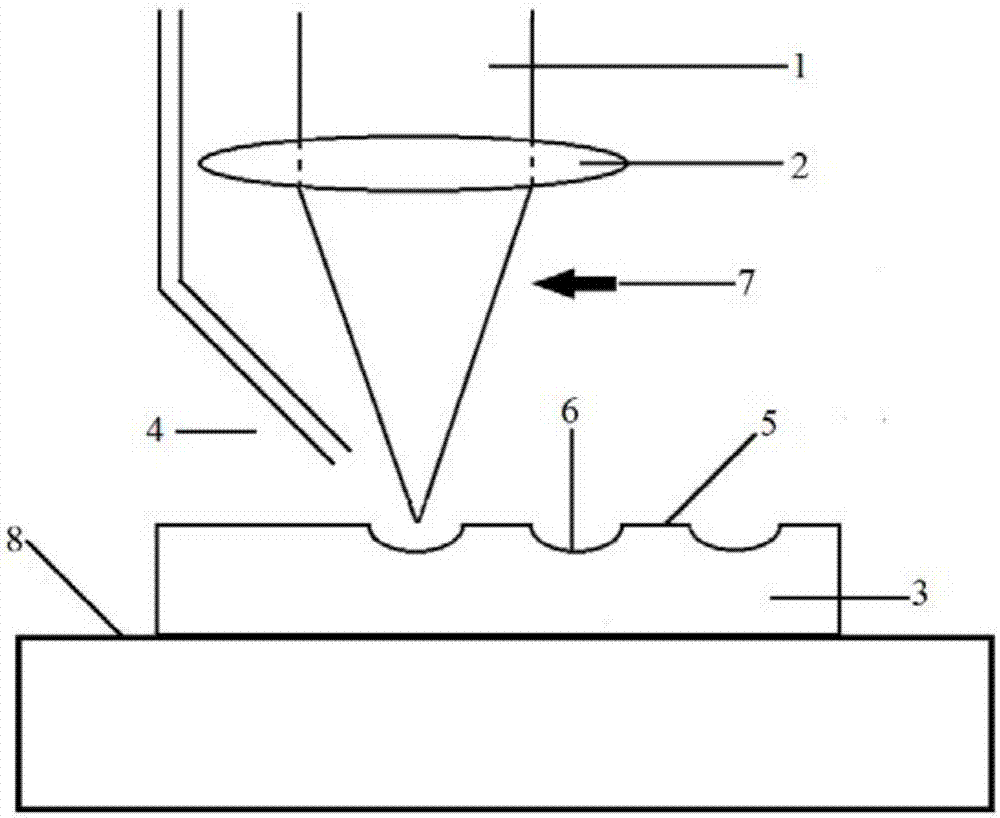

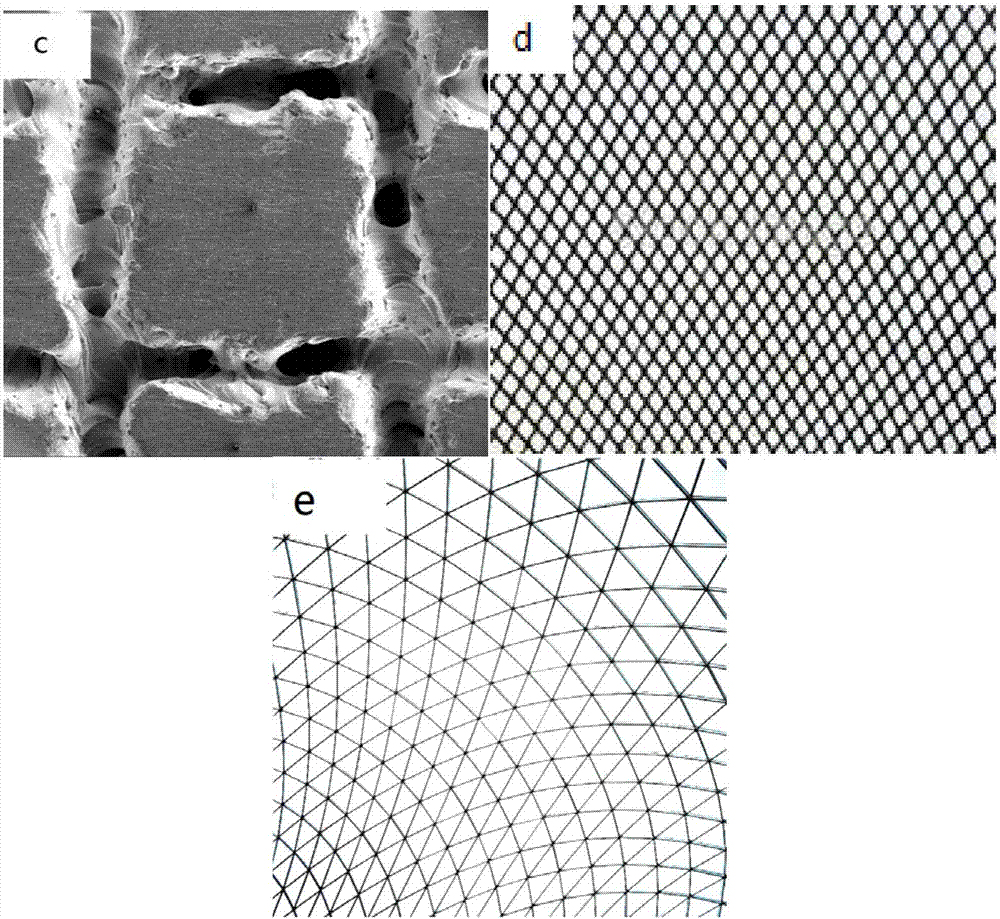

[0046] (2) Put the titanium alloy sample on the temperature-controllable heating furnace and place it on the laser processing workbench. First heat the sample to 300°C, then turn on the gas switch, and fill the surface of the sample with high-purity nitrogen gas with a flow rate of 15L / min, then turn on the pulse laser (Nd:YAG pulse laser), and perform laser scanning according to the preset laser parameters and numerical c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com