Bulk acoustic resonator based on mono-crystal piezoelectric film and preparation method thereof

A technology of bulk acoustic wave resonator and piezoelectric film, which is applied in the direction of electrical components, impedance networks, etc., can solve the problems of low surface uniformity of single crystal LiNbO3 film, impracticality, and poor surface uniformity of thin slices limited by thickness, and achieve Improve the electromechanical coupling coefficient and quality factor, high Q value, and improve the effect of electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

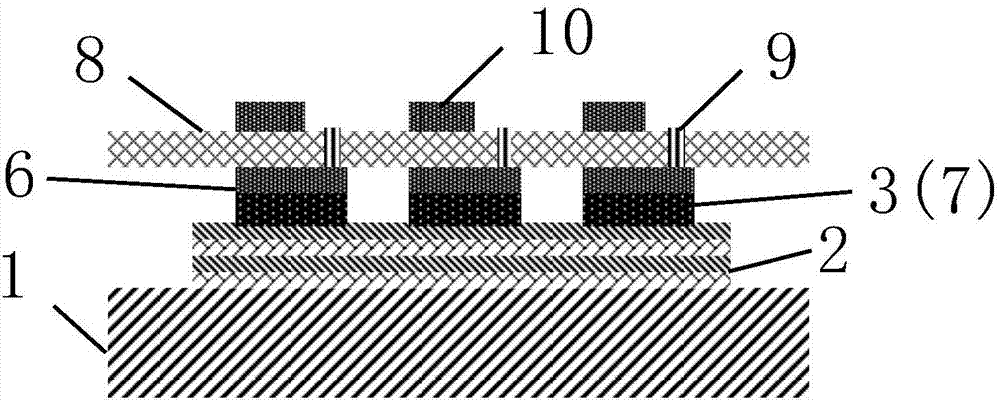

[0052] refer to figure 1 The bulk acoustic wave resonator based on the single crystal piezoelectric thin film of the present invention is described, figure 1 A cross-sectional view of a bulk acoustic wave resonator structure is shown.

[0053] Such as figure 1 As shown, the structure of the bulk acoustic wave resonator based on the single crystal piezoelectric thin film of the present invention is as follows:

[0054] A bulk acoustic wave resonator based on a single crystal piezoelectric thin film includes: a substrate 1, an acoustic reflection layer 2 formed on the substrate 1, and a piezoelectric sandwich structure covering the acoustic reflection layer. The piezoelectric sandwich structure includes sequentially stacked The lower electrode 6, the single crystal piezoelectric film 8, and the upper electrode 10; the single crystal piezoelectric film 8 is provided with a vertical through hole 9 electrically interconnected with the lower electrode 6; the vertical through hole ...

Embodiment 2

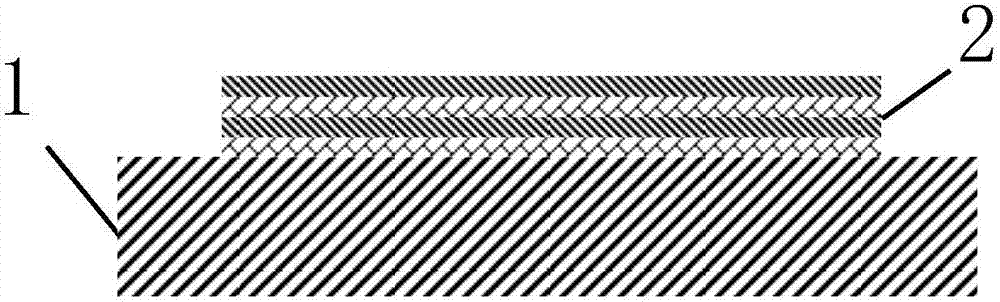

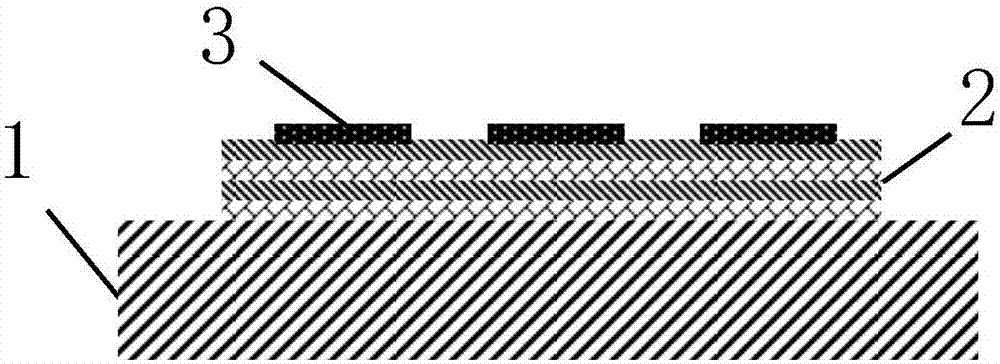

[0064] refer to Figure 2 to Figure 10 The preparation method of the bulk acoustic wave resonator based on the single crystal piezoelectric film of the present invention is described, Figure 2 to Figure 10 It shows the cross-sectional view of the structure obtained by sequential implementation of the method for preparing the bulk acoustic wave resonator.

[0065] The present invention is based on the bulk acoustic wave resonator of single crystal piezoelectric thin film, and its preparation method comprises the following steps:

[0066] S101, using magnetron sputtering and plasma chemical vapor deposition (PECVD) methods to alternately deposit 4 to 7 layers of high acoustic impedance material tungsten and low acoustic impedance material silicon dioxide on the surface of silicon substrate 1, each layer The thickness is 300nm, forming the Bragg acoustic reflection layer 2, such as figure 2 shown;

[0067] S102, on the surface of the Bragg reflection layer 2, deposit a 10nm ...

Embodiment 3

[0076] refer to Figure 11 The structure of the G-S-G coplanar line standard device of the bulk acoustic wave resonator of the present invention is described, and the bulk acoustic wave resonator is prepared by the method described in Example 2, Figure 11 It is a top view of the device G-S-G coplanar line standard device structure.

[0077] Such as Figure 11 As shown, the two common ground electrodes 11 and the vertical through hole 9 electrically interconnected with the lower electrode form a G-S-G coplanar line standard device structure, or the two common ground electrodes 11 and the upper electrode 10 form a G-S-G coplanar line standard device structure.

[0078] The upper electrode 10 adopts an irregular polygon to reduce the influence of parasitic capacitance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com