Solid solution-modified sodium bismuth titanate leadless piezoelectric ceramics and preparation method thereof

A bismuth sodium titanate-based, lead-free piezoelectric technology, applied in the field of functional ceramics, can solve the problems of high coercive field, difficult polarization, high production cost, etc., to improve piezoelectricity and electromechanical coupling coefficient, grain size Uniform distribution and improved electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

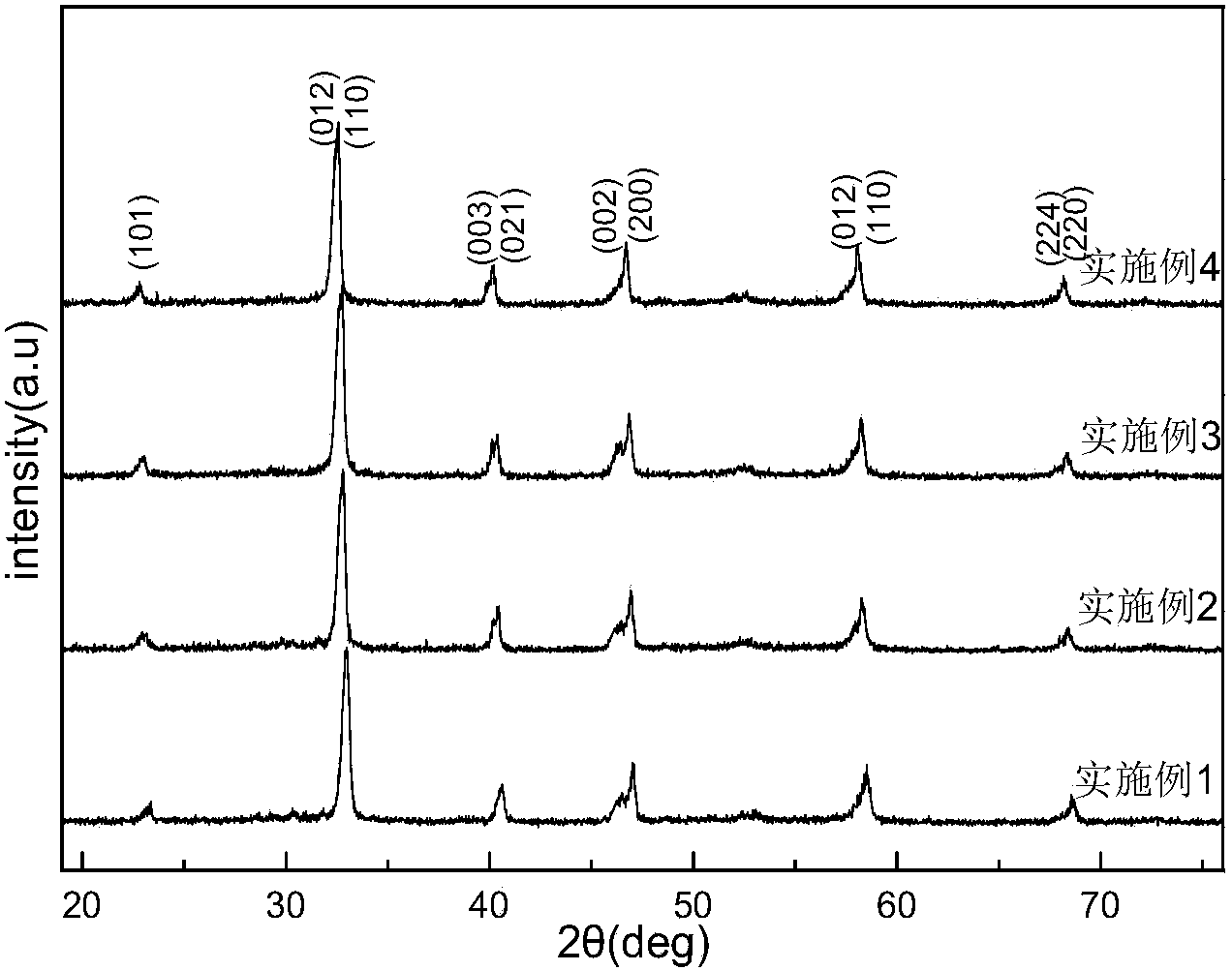

Embodiment 1

[0033] The general composition formula of the lead-free piezoelectric ceramics prepared in this embodiment is:

[0034] 0.96(0.74Na 0.5 Bi 0.5 TiO 3 -0.26SrTiO 3 )-0.04Ba(Zr 0.05 Ti 0.95 )O 3 .

[0035] Preparation method and performance test:

[0036] (1) Choose anhydrous NaCO 3 、 Bi 2 o 3 , SrCO 3 、BaCO 3 , ZrO 2 and TiO 2 As the raw material, it is weighed according to the general composition formula, and then mixed by planetary wet ball milling process to obtain powder A (absolute ethanol is used as the ball milling medium, and the ball milling time is 4h); the dried powder A is placed in the muffle In the furnace, the temperature was raised from room temperature to 850 °C at a rate of 3 °C / min, and the temperature was kept for 1 hour. After the temperature was kept, the porcelain powder was cooled to room temperature with the furnace; Deionized water is used as the ball milling medium, and the ball milling time is 4 hours);

[0037] (2) Add a binder to the...

Embodiment 2

[0042] The general composition formula of the lead-free piezoelectric ceramics prepared in this example is

[0043] 0.94 (0.74Na 0.5 Bi 0.5 TiO 3 -0.26SrTiO 3 )-0.06Ba(Zr 0.05 Ti 0.95 )O 3 .

[0044] Preparation method and performance test:

[0045] (1) Choose anhydrous NaCO 3 、 Bi 2 o 3 , SrCO 3 、BaCO 3 , ZrO 2 and TiO 2 As the raw material, weigh the material according to the general composition formula, and then use the planetary wet ball milling process to mix the materials to obtain powder A (absolute ethanol is used as the ball milling medium, and the ball milling is 4h); the dried powder A is placed in the muffle furnace Raise from room temperature to 800°C at a speed of 3°C / min, keep warm for 2 hours, and then cool down to room temperature with the furnace to obtain porcelain powder; finely grind the porcelain powder to obtain powder B (using wet ball milling process to deionize Water is the ball milling medium, ball milling 4h);

[0046] (2) Add a bind...

Embodiment 3

[0052] The general composition formula of the lead-free piezoelectric ceramics prepared in this example is

[0053] 0.93(0.9Na 0.5 Bi 0.5 TiO 3 -0.1CaTiO 3 )-0.07Ba(Zr 0.05 Ti 0.95 )O 3 .

[0054] Preparation method and performance test:

[0055] (1) Choose anhydrous NaCO 3 、 Bi 2 o 3 , CaCO 3 、BaCO 3 , ZrO 2 and TiO 2 As the raw material, it is weighed according to the general composition formula, and then mixed by planetary wet ball milling process to obtain powder A (absolute ethanol is used as the ball milling medium, and the ball milling time is 4h); the dried powder A is placed in the muffle In the furnace, the temperature was raised from room temperature to 800 °C at a rate of 5 °C / min, and the temperature was kept for 2 hours. After the heat preservation, the porcelain powder was cooled to room temperature with the furnace; Deionized water is used as the ball milling medium, and the ball milling time is 4 hours);

[0056] (2) Add a binder to the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com