Hard alloy product, preparation method thereof and device for preparing hard alloy product

A cemented carbide and product technology, applied in the field of powder metallurgy, can solve the problems of high cost, high difficulty and low quality, and achieve the effects of low production cost, fast forming speed and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

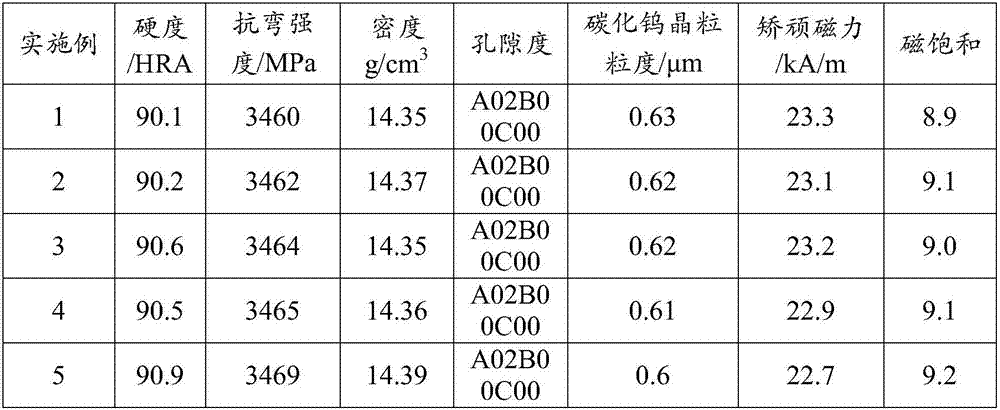

Embodiment 1

[0049] The preparation method of the cemented carbide product of the present embodiment may further comprise the steps:

[0050] (1) Carbide powder and binding agent are carried out kneading, make feed, wherein, cemented carbide powder accounts for 93wt% of feed, and cemented carbide powder comprises: tungsten carbide powder of 88wt% and 12wt% The cobalt powder, the binder accounts for 7wt% of the feed, and the binder includes: 69wt% of paraffin, 25wt% of ethylene-vinyl acetate copolymer, 5wt% of high-density polyethylene and 1wt% of surface active hard Fatty acid; the average particle size of the tungsten carbide powder is 0.6 μm, and the average particle size of the cobalt powder is 0.7 μm.

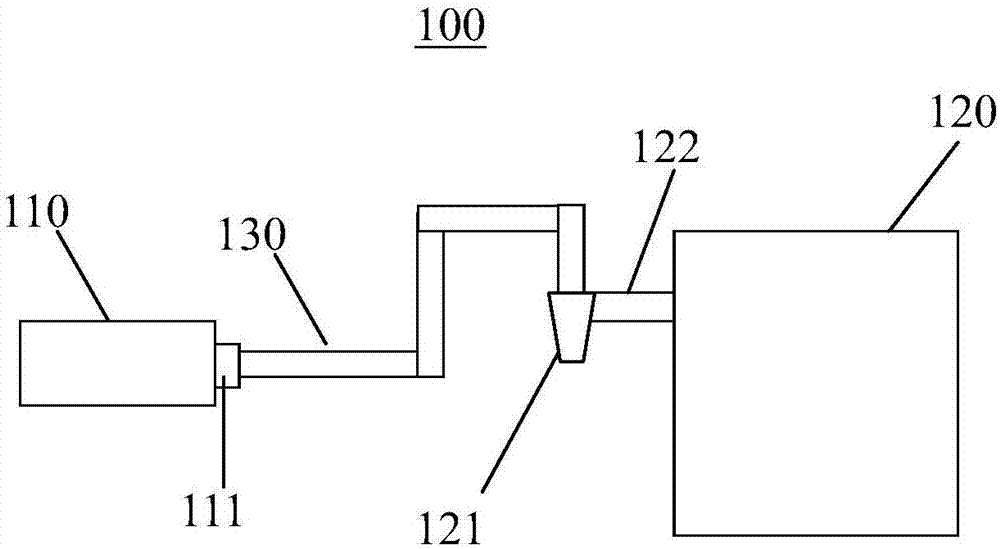

[0051] (2) The feed is placed in the extruder so that the feed is extruded through the nozzle of the numerically controlled machine tool connected to the extruder, and the extruded feed is controlled by the numerically controlled machine tool to accumulate in layers to obtain cemented c...

Embodiment 2

[0055] The preparation method of the cemented carbide product of the present embodiment may further comprise the steps:

[0056] (1) Mixing cemented carbide powder and binder to prepare feed, wherein cemented carbide powder accounts for 94wt% of the feed, and cemented carbide powder includes: 94wt% tungsten carbide powder and 6wt% The cobalt powder, the binder accounts for 6wt% of the feed, and the binder includes: 79wt% of paraffin wax, 15wt% of ethylene-vinyl acetate copolymer, 5wt% of high-density polyethylene and 1wt% of surface active hard Fatty acid; the average particle size of the tungsten carbide powder is 1.0 μm, and the average particle size of the cobalt powder is 1.2 μm.

[0057] (2) The feed is placed in the extruder so that the feed is extruded through the nozzle of the numerically controlled machine tool connected to the extruder, and the extruded feed is controlled by the numerically controlled machine tool to accumulate in layers to obtain cemented carbide pr...

Embodiment 3

[0061] The preparation method of the cemented carbide product of the present embodiment may further comprise the steps:

[0062] (1) Mixing cemented carbide powder and binder to prepare feed, wherein cemented carbide powder accounts for 95wt% of the feed, and cemented carbide powder includes: 90wt% tungsten carbide powder and 10wt% The cobalt powder, the binder accounts for 5wt% of the feed, and the binder includes: 72wt% of paraffin, 25wt% of ethylene-vinyl acetate copolymer, 2wt% of high-density polyethylene and 1wt% of surface active hard Fatty acid; the average particle size of the tungsten carbide powder is 0.8 μm, and the average particle size of the cobalt powder is 1.0 μm.

[0063] (2) The feed is placed in the extruder so that the feed is extruded through the nozzle of the numerically controlled machine tool connected to the extruder, and the extruded feed is controlled by the numerically controlled machine tool to accumulate in layers to obtain cemented carbide produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com