Double column production method of gamma-aminobutyric acid by immobilized cell and D101 resin

A D101, aminobutyric acid technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of high cost of biosynthesis of GABA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

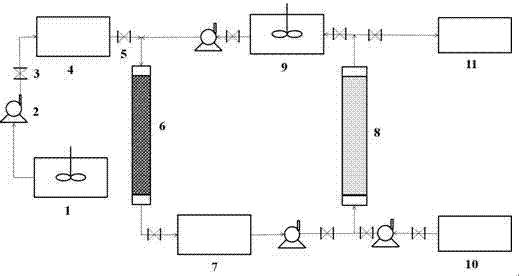

Image

Examples

Embodiment 1

[0045] A kind of method of producing gamma-aminobutyric acid with immobilized cell and D101 resin double-column type of the present invention mainly comprises the following steps:

[0046] ①Refer to the cell immobilization method of Jiao Yang, Wang Jianmin and Yang Shengyuan in the abstract (Journal of Nuclear Agriculture, 2009, 23 (6): 1026-1031), and prepare immobilized Enterococcus faecium GDMCC 60203 by calcium alginate cell embedding method Cells, and then the immobilized Enterococcus faecium GDMCC 60203 cells were loaded into a column with a 0.2 mol / L acetic acid-sodium acetate buffer solution of pH 4.2 according to a conventional method to prepare an immobilized cell reaction column;

[0047] ② Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then prepare the auxiliary reaction column with 0.2 mol / L acetic acid-sodium acetate buffer solution of pH 4.2 according to the conventional method; ...

Embodiment 2

[0057] A kind of method of producing gamma-aminobutyric acid with immobilized cell and D101 resin double-column type of the present invention mainly comprises the following steps:

[0058] ① Referring to the cell immobilization method of Shen Yu et al. in the abstract (Fine Chemical Industry, 2008, 25(5): 459-462), the immobilized Enterococcus faecium GDMCC 60203 cells were prepared by embedding with carrageenan and gelatin, and then the pH 4.2 0.2 mol / L acetic acid-sodium acetate buffer solution to prepare the immobilized Enterococcus faecium GDMCC 60203 cells into the column according to the conventional method to prepare the immobilized cell reaction column;

[0059] ② Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then prepare the auxiliary reaction column with 0.2 mol / L acetic acid-sodium acetate buffer solution of pH 4.2 according to the conventional method;

[0060] ③ Combine the immobi...

Embodiment 3

[0069] A kind of method of producing gamma-aminobutyric acid with immobilized cell and D101 resin double-column type of the present invention mainly comprises the following steps:

[0070] ① Referring to Zhao Weirui et al.’s abstract (Journal of Chemical Engineering of Universities, 2015, 29(1): 138-144), firstly, an organic solvent with low dielectric constant (0.68) was used to treat Enterococcus faecium GDMCC 60203 cells were permeabilized, and then referring to the cell immobilization method of Jiao Yang et al. Enterococcus GDMCC 60203 cells, and then use 0.2 mol / L acetic acid-sodium acetate buffer solution with pH 4.2 to pack the immobilized Enterococcus faecium GDMCC 60203 cells into a column according to a conventional method to prepare an immobilized cell reaction column;

[0071] ② Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then prepare the auxiliary reaction column with 0.2 mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com