Water feeding pipe and preparation method thereof

A water supply pipe, linear low-density technology, applied in the field of water supply pipes and their preparation, can solve the problems of insufficient mechanical strength, flame retardancy, toughness and aging resistance, and achieve good insulation, corrosion resistance, anti-corrosion, and anti-aging properties. good corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

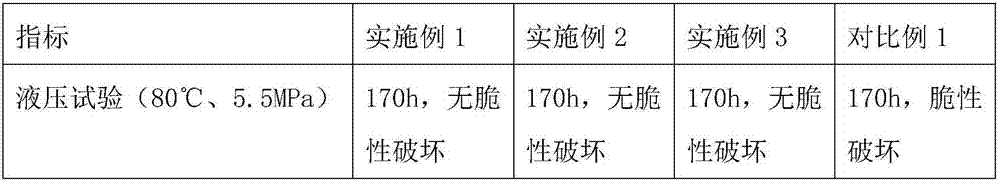

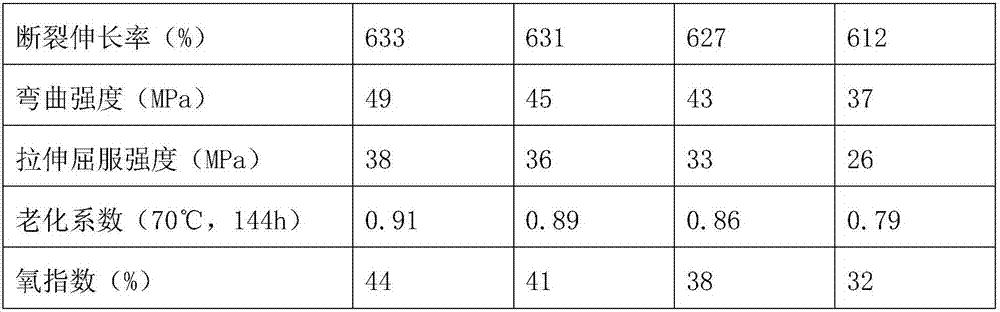

Examples

Embodiment 1

[0040] A water supply pipe, comprising the following raw materials in parts by weight: 95 parts of metallocene linear low density polyethylene, 2.5 parts of chromium carbonate, 4.5 parts of fumed white carbon black, 2.5 parts of nano-active calcium carbonate, metallocene linear low density polyethylene wax 1.5 parts, 1.5 parts of phthalates, 0.3 parts of γ-aminopropyl triethoxysilane, 0.2 parts of rose essential oil, 0.4 parts of dibutyltin dilaurate, 2.5 parts of modification additives, hydroxy distearate 1.5 parts of aluminum, 30 parts of hollow glass microspheres, 9 parts of aluminum hydroxide, 3 parts of nano-zirconium carbide, 2 parts of aluminum silicate, 3 parts of glass fiber, 0.3 parts of heat stabilizer, 0.2 parts of light stabilizer, and 0.4 parts of antioxidant part, 0.6 part of compatibilizer and 0.5 part of plasticizer;

[0041] The modification aid is composed of the following raw materials in parts by weight: 35 parts of metallocene linear low-density polyethylen...

Embodiment 2

[0058] A water supply pipe, comprising the following raw materials in parts by weight: 90 parts of metallocene linear low-density polyethylene, 2 parts of chromium carbonate, 4 parts of fumed white carbon black, 2 parts of nano-active calcium carbonate, metallocene linear low-density polyethylene wax 1 part, 1 part of phthalate, 0.2 part of γ-aminopropyltriethoxysilane, 0.1 part of rose essential oil, 0.3 part of dibutyltin dilaurate, 2 parts of modifying additives, hydroxy distearate 1 part of aluminum, 20 parts of hollow glass microspheres, 6 parts of aluminum hydroxide, 2 parts of nano-zirconium carbide, 1 part of aluminum silicate, 1 part of glass fiber, 0.2 parts of heat stabilizer, 0.1 part of light stabilizer, 0.2 parts of antioxidant part, 0.3 part of compatibilizer and 0.2 part of plasticizer;

[0059] The modification aid is composed of the following raw materials in parts by weight: 30 parts of metallocene linear low density polyethylene, 15 parts of polyphthalamide...

Embodiment 3

[0076] A water supply pipe, comprising the following raw materials in parts by weight: 100 parts of metallocene linear low density polyethylene, 3 parts of chromium carbonate, 5 parts of fumed white carbon black, 3 parts of nano-active calcium carbonate, metallocene linear low density polyethylene wax 2 parts, 2 parts of phthalates, 0.4 parts of γ-aminopropyltriethoxysilane, 0.3 parts of rose essential oil, 0.5 parts of dibutyltin dilaurate, 3 parts of modifying additives, hydroxy distearate 2 parts of aluminum, 40 parts of hollow glass microspheres, 12 parts of aluminum hydroxide, 4 parts of nano-zirconium carbide, 3 parts of aluminum silicate, 5 parts of glass fiber, 0.4 parts of heat stabilizer, 0.3 parts of light stabilizer, and 0.6 parts of antioxidant part, 0.9 part of compatibilizer and 0.8 part of plasticizer;

[0077] The modification aid is composed of the following raw materials in parts by weight: 40 parts of metallocene linear low-density polyethylene, 20 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com