Processing method of forged bowl head hanging plate

A bowl head hanging board and processing method technology, applied in metal processing equipment and other directions, can solve the problems of smoke and dust, low strength resistance, affecting the atmospheric environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

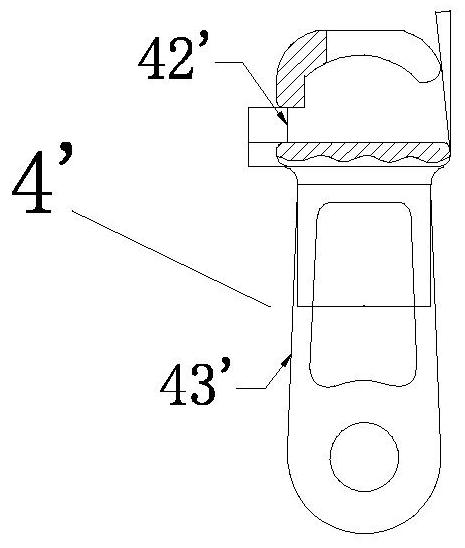

[0030] from figure 1 , figure 2 , image 3 , Figure 4 Analysis: The ball and socket part of the head is 41', which is square, and the hanging plate part is 43', which is flat. The materials used in the two parts are quite different, and the shape of the ball socket is more complicated, and the accuracy requires the inspection of the go-no-go gauge. To achieve integral forging, we have adopted the following technical solutions.

[0031] The production process route of the forged bowl head hanging plate of the present invention

[0032] Purchasing raw materials - blanking - upsetting billet - whole forging product appearance - cutting burr - punching ball socket - grinding burr - hot dip galvanizing - factory inspection - packaging for delivery

[0033] The above-mentioned purchase of raw materials, trimming, grinding, hot-dip galvanizing, factory inspection, and packaging are all prior technologies.

[0034] The unique technology of the present invention is:

[0035] A:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com