DC capacitor for super high power three-level inverter

A three-level frequency converter and ultra-high power technology, applied in capacitors, fixed capacitors, multiple fixed capacitors, etc., can solve problems such as the size limitation of DC capacitors, and achieve the effect of good internal heat dissipation, strong endurance, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

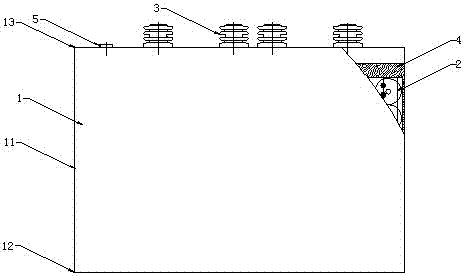

[0024] exist figure 1 It can be seen that the capacitor is mainly composed of the shell (1), the core (2), the terminal (3), the filled resin (4) and the pressure relief valve (5). The shell (1) is composed of a shell (11), a shell bottom (12) and a shell cover (13).

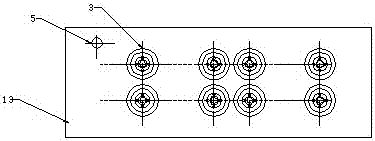

[0025] exist figure 2 It can be seen in the figure that the terminal block (3) is installed on the shell cover (13) of the shell (1). There are 4 connection terminals (3) in the upper and lower rows of the shell cover (13), and there are 8 connection terminals (3) in total. Terminal (3a) and terminal (3b) are the electrodes of a group of capacitors, terminal (3c) and terminal (3d) are electrodes of a group of capacitors, terminal (3e) and terminal (3f) are one group The electrodes of the capacitor, the terminal (3g) and the terminal (3h) are the electrodes of a group of capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com