Preparation method of high-performance sodium ion battery cathode material (VO)2P2O7 composite

A technology of sodium ion battery and composite material, which is applied in the field of high-performance sodium ion battery negative electrode material 2P2O7/C composite material, can solve the problems of poor cycle performance of negative electrode material, cumbersome synthesis process, complicated operation, etc., and achieves good electrochemical performance, Simple and easy-to-obtain raw materials, environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, (VO) 2 P 2 o 7 / C composite preparation

[0035] 10mmol V 2 o 5 ,20mmol NH 4 h 2 PO 4 ,Add 20mmol of methacrylic acid into a 25mL beaker, add 20mL of deionized water and stir evenly, place in a water bath at 80°C to stir and heat, add 1mL of 5% ammonium persulfate aqueous solution as an initiator under constant stirring, and continue to stir and heat for 2 hours until a viscous solid is formed. Transfer to a 100°C oven for drying for 5 hours, and grind to obtain a precursor powder. The final product can be obtained by heating the precursor powder to 600°C and calcining for 5 hours in an Ar atmosphere.

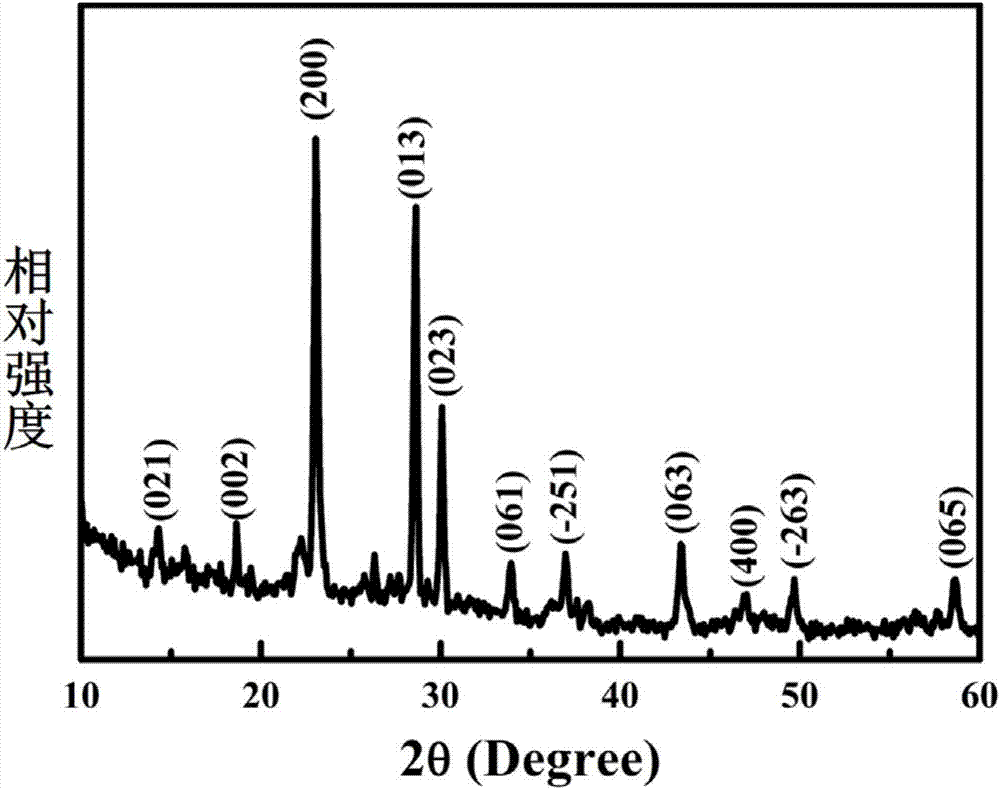

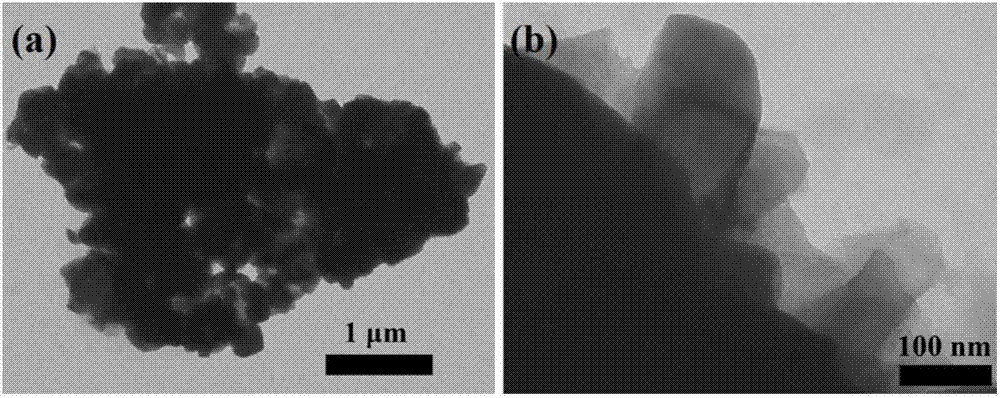

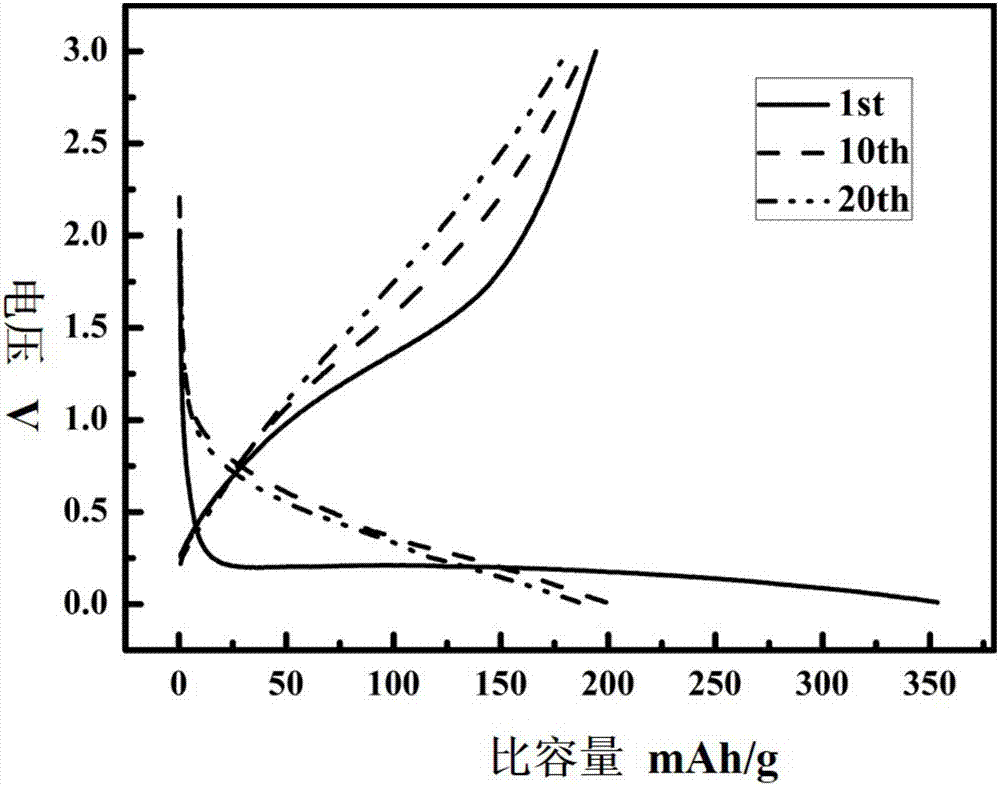

[0036] The product adopts Bruker D8 ADVANCE X-ray powder diffractometer to carry out phase analysis with Cu Kα ray (wavelength scanning step speed is 0.08 ° / second), the result is as follows figure 1 shown by figure 1 It can be seen that the final product is pure phase (VO) 2 P 2 o 7 / C complex, which can be used as an anode active material fo...

Embodiment 2

[0037] Embodiment 2, (VO) 2 P 2 o 7 / C composite preparation

[0038] 20mmol ammonium metavanadate, 20mmol NaH 2 PO 4 , add 25mmol methacrylic acid into a 25mL beaker, add 20mL deionized water and stir evenly, place in a water bath at 80°C for stirring and heating, add 1mL of 5% sodium persulfate aqueous solution as an initiator, continue stirring and heating for 1 hour until sticky A thick solid formed. Transfer to a 110°C oven for drying for 4 hours, and grind to obtain a precursor powder. Precursor powder in N 2 The final product can be obtained by calcining at 600°C for 6 hours in the atmosphere.

[0039] The product was subjected to phase analysis with Cu Kα rays (wavelength scan step speed of 0.08° / sec) using a Bruker D8 ADVANCE X-ray powder diffractometer, and the results showed that it was phase-pure (VO) 2 P 2 o 7 / C complex, can be used as the negative electrode active material of sodium ion battery.

Embodiment 3

[0040] Embodiment 3, (VO) 2 P 2 o 7 / C composite preparation

[0041] With 20mmol sodium metavanadate, 20mmol Na 2 HPO 4 , add 20mmol acrylic acid to a 25mL beaker, add 20mL deionized water and stir evenly, place in a 70°C water bath and stir and heat, add 1mL 5% mass concentration of sodium persulfate aqueous solution as an initiator, continue stirring and heating for 1 hour until viscous Solids are formed. Transfer to a 100°C oven for drying for 6 hours, and grind to obtain a precursor powder. Precursor powder in N 2 The final product can be obtained by calcining at 450°C for 8 hours in the atmosphere.

[0042] The product was subjected to phase analysis with Cu Kα rays (wavelength scan step speed of 0.08° / sec) using a Bruker D8 ADVANCE X-ray powder diffractometer, and the results showed that it was phase-pure (VO) 2 P 2 o 7 / C complex, can be used as the negative electrode active material of sodium ion battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com