A kind of preparation method of lithium ion battery composite negative electrode material

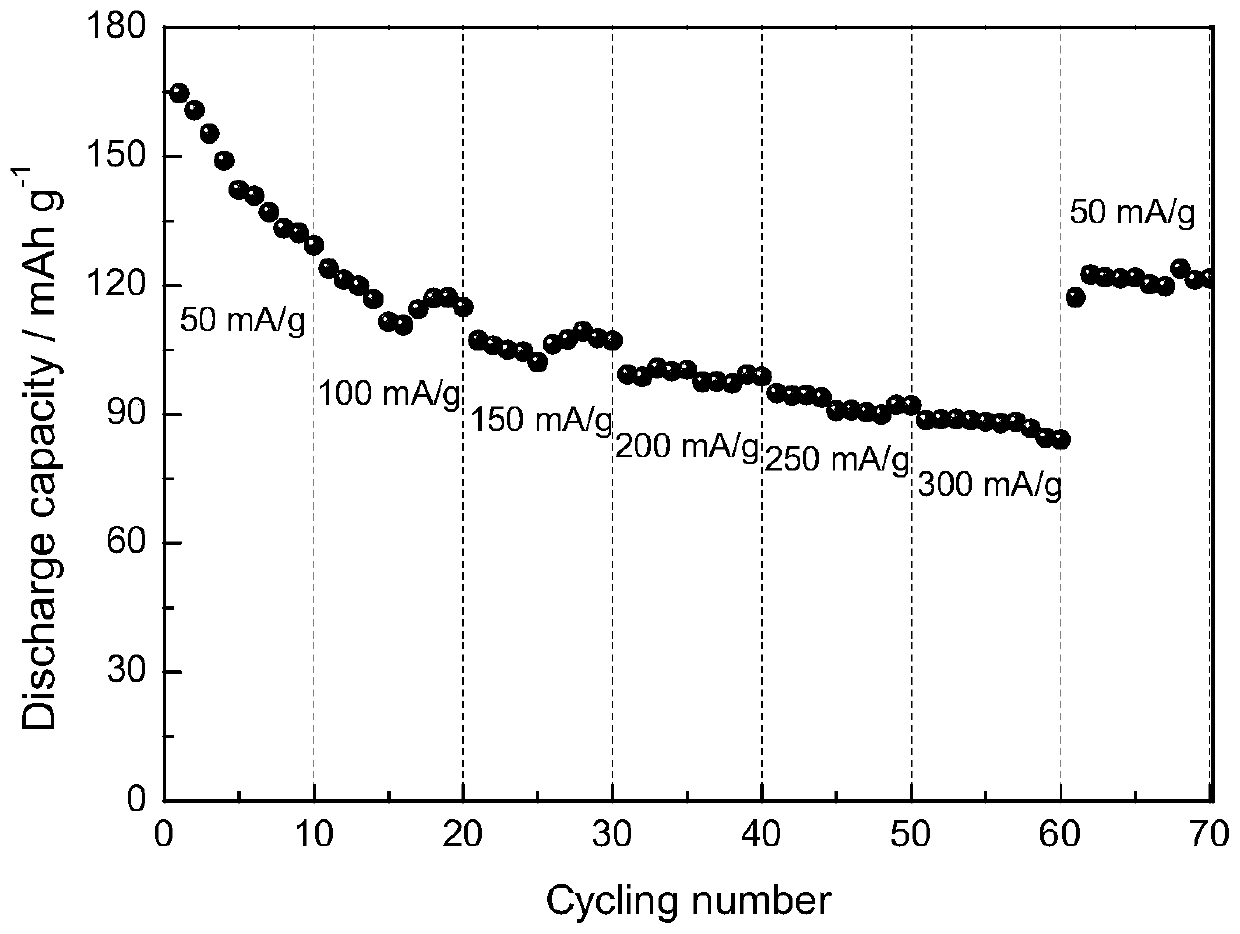

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of fast capacity decay, poor rate performance, low electronic conductance and ion conductance, and achieve high reproducibility and improved Effects of energy density, power density, and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

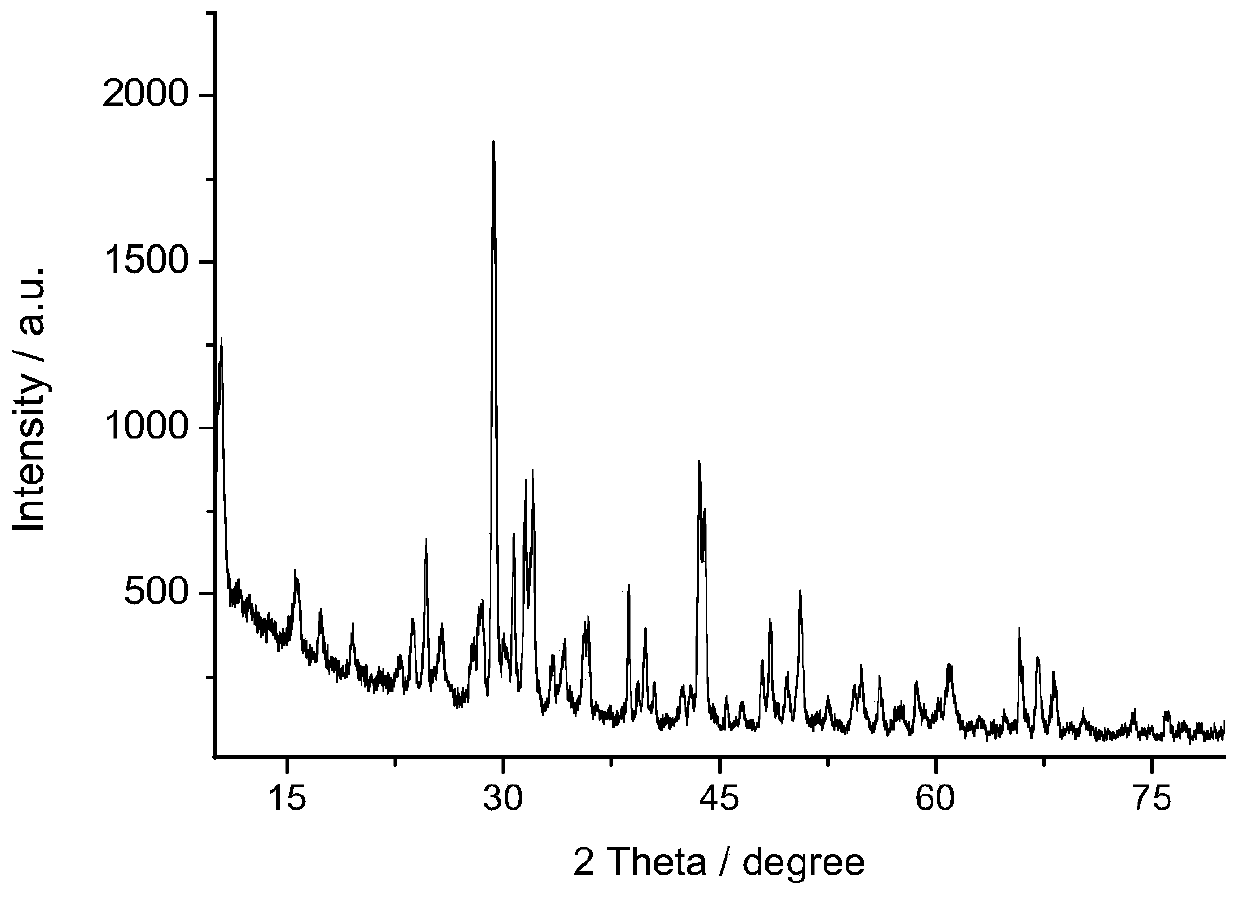

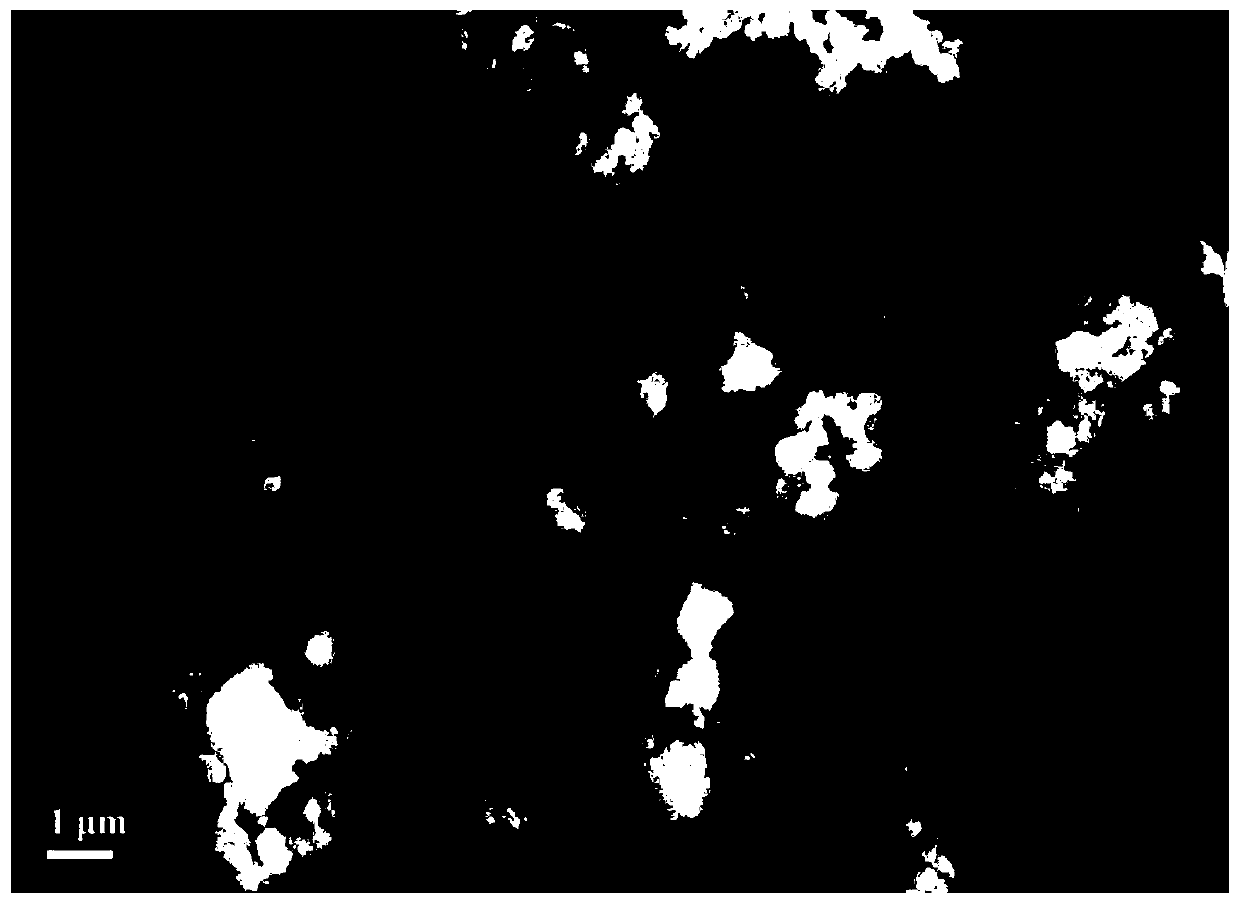

[0029] 0.06mol of anatase titanium dioxide (TiO 2 ), 0.02mol sodium acetate (CH 3 COONa), 0.01mol barium carbonate (BaCO 3 ) into an agate jar and add an appropriate amount of absolute ethanol for ball milling for 10 hours, put the agate jar in an oven to dry at 60°C, cool to room temperature, then put it in a muffle furnace for pre-burning at 400°C for 4 hours, cool to room temperature, and then dry at 1000°C Calcined at ℃ for 10h, cooled to room temperature, ball milled for 24h, and sieved to obtain the negative electrode material BaNa 2 Ti 6 o 14 Precursor. 0.01mol BaNa 2 Ti 6 o 14 , 0.00033mol lithium hydroxide (LiOH), 0.00056mol lanthanum nitrate (La(NO 3 ) 3 ) and 0.001mol tetrabutyl titanate were dissolved in ethylene glycol, stirred for 3.5h, then placed in a closed reaction kettle and kept at 180°C for 12h, cooled, and dried at 100°C for 12h, and the resulting mixture was placed in a In a Furnace, bake at 700°C for 12 hours, and cool to room temperature to o...

Embodiment 2

[0031] 0.06mol of rutile titanium dioxide (TiO 2 ), 0.0201mol sodium hydroxide (NaOH), 0.01mol barium carbonate (BaCO 3 ) into an agate jar and add an appropriate amount of absolute ethanol for ball milling for 10 hours, put the agate jar in an oven to dry at 60°C, cool to room temperature, and then put it in a muffle furnace for pre-burning at 600°C for 4 hours, cool to room temperature, and then dry at 900°C Calcined at ℃ for 10h, cooled to room temperature, ball milled for 24h, and sieved to obtain the negative electrode material BaNa 2 Ti 6 o 14 . 0.01mol BaNa 2 Ti 6 o 14 , 0.000528mol lithium acetate (CH 3 COOLi·2H 2 O), 0.000896mol lanthanum acetate and 0.0016mol tetrabutyl titanate were dissolved in ethanol, stirred for 5h, then placed in a closed reaction kettle and kept at 160°C for 12h, cooled, dried at 80°C for 12h, and the resulting mixture Put it in a muffle furnace, bake at 600°C for 12 hours, and cool to room temperature to obtain BaNa, a negative elect...

Embodiment 3

[0033] 0.06mol of amorphous titanium dioxide (TiO 2 ), 0.02005mol sodium hydroxide (NaOH), and 0.01mol barium nitrate were placed in an agate jar, added an appropriate amount of absolute ethanol and ball-milled for 10 hours, put the agate jar in an oven to dry at 60°C, cooled to room temperature, and then placed in a muffle furnace Pre-calcined at 600°C for 6h, cooled to room temperature, calcined at 1100°C for 15h, cooled to room temperature, ball milled for 24h, and sieved to obtain the negative electrode material BaNa 2 Ti 6 o 14 . 0.01mol BaNa 2 Ti 6 o 14 , 0.000792mol of lithium hydroxide (LiOH), 0.001344mol of lanthanum nitrate and 0.0024mol of isopropyl titanate were dissolved in benzyl alcohol, stirred for 3-5h, then placed in a closed reactor and kept at 200°C for 12h, cooled, Dry at 80°C for 12 hours, put the resulting mixture in a muffle furnace, bake at 800°C for 12 hours, and cool to room temperature to obtain BaNa, a negative electrode material for lithium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com