Ternary system osmium-tungsten diboride hard material as well as preparation method and application thereof

A hard material, boron compound technology, applied in the field of ternary osmium tungsten diboride hard material and its preparation, can solve the problems of increasing the final cost of the product, unfavorable application, etc., and achieve high hardness and chemical stability, process Simple, high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation: In a glove box filled with argon gas, osmium powder (Os), tungsten powder (W) and boron powder (B) with a purity of 99.99% are mixed, wherein the molar ratio of osmium powder to tungsten powder is 10: 0. Os, W and boron powder (B) are mixed in a molar ratio of 1:3. A total of six tungsten carbide grinding balls were used, with a size of 11.20mm, and the mass ratio of the balls to the mixed powder was 4:1. Fix the tungsten carbide ball mill jar with powder and balls on the high energy ball mill. The total time of ball milling is 40h. In order to prevent the engine from overheating, every 1h of ball milling is stopped for 20min to obtain osmium boride powder.

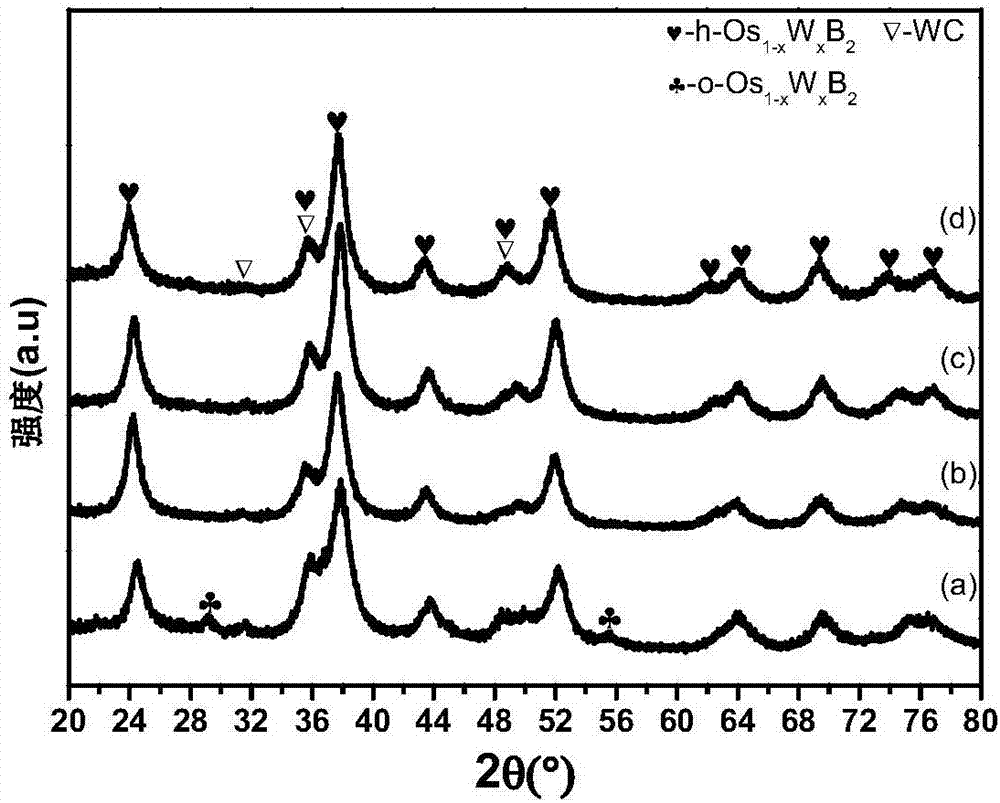

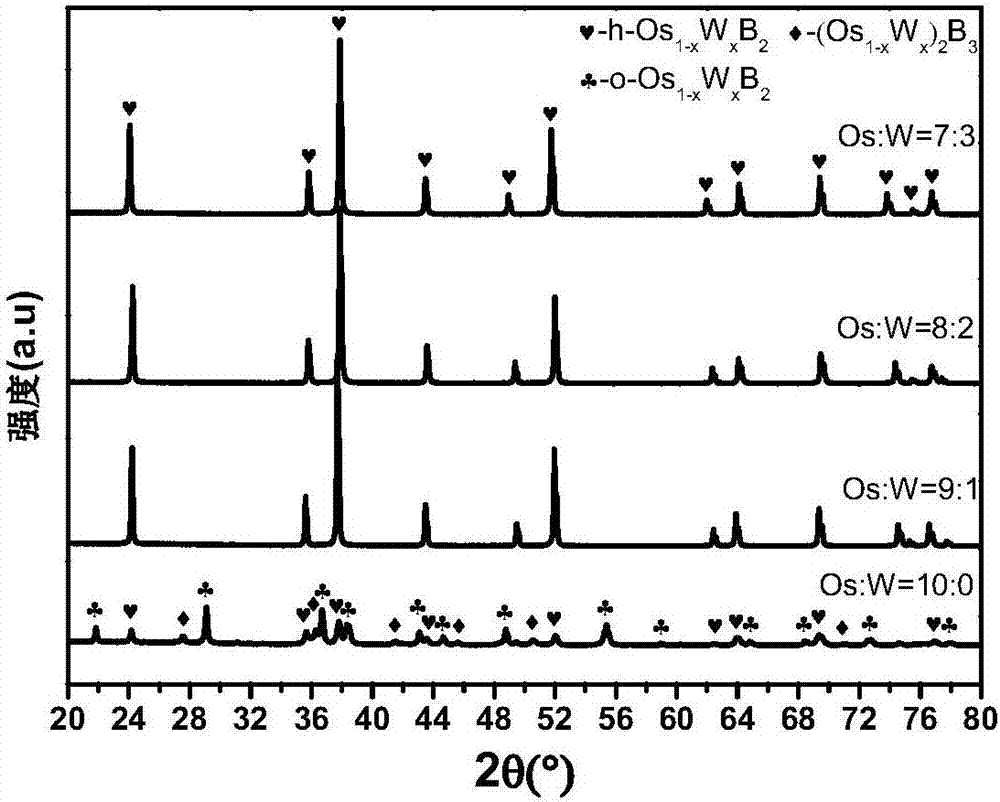

[0034] 2. Test: The above powder is sampled, and its phase analysis is carried out by XRD. figure 1 As shown in (a), the main phase of the mixed powder after ball milling for 40 hours is ReB with hexagonal structure 2 TypeOsB 2Powder, no phases such as (osmium) Os tungsten) W and (boron) B were...

Embodiment 2

[0036] 1. Preparation: In a glove box full of argon, osmium powder (Os), tungsten powder (W) and boron powder (B) with a purity of 99.99% are used, wherein the mol ratio of osmium powder to tungsten powder is 9: 1. Os, W and B are mixed with a molar ratio of 1:3. A total of six tungsten carbide grinding balls were used, with a size of 11.20mm, and the mass ratio of the balls to the mixed powder was 4:1. Fix the tungsten carbide ball mill jar with powder and balls on the high energy ball mill. The total time of ball milling is 40h. In order to prevent the engine from overheating, every 1h of ball milling is stopped for 20min to obtain osmium tungsten diboride powder.

[0037] 2. Test: Take a sample of the above-mentioned powder, and use XRD to carry out phase analysis on it. figure 1 As shown in (b), the main phase of the mixed powder after ball milling for 40 hours is ReB with hexagonal structure. 2 Type Os 0.9 W 0.1 B 2 Powder, the synthesis process is a solid-phase di...

Embodiment 3

[0039] 1. Preparation: In a glove box full of argon, osmium powder (Os), tungsten powder (W) and boron powder (B) with a purity of 99.99% are used, wherein the mol ratio of osmium powder to tungsten powder is 8: 2. Os, W and B are mixed with a molar ratio of 1:3. A total of six tungsten carbide grinding balls were used, with a size of 11.20mm, and the mass ratio of the balls to the mixed powder was 4:1. Fix the tungsten carbide ball mill jar with powder and balls on the high energy ball mill. The total time of ball milling is 40h. In order to prevent the engine from overheating, every 1h of ball milling is stopped for 20min to obtain osmium tungsten diboride powder.

[0040] 2. Test: Take a sample of the above-mentioned powder, and use XRD to carry out phase analysis on it. figure 1 As shown in (c), the mixed powders were milled for 40 hours to obtain the main phase ReB with hexagonal structure. 2 Type Os 0.8 W 0.2 B 2 Powder, the synthesis process is a solid-phase diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com