Mud-proof polycarboxylic acid type high-efficiency water reducing agent and preparation method thereof

A high-efficiency water-reducing agent and polycarboxylic acid-based technology, which is applied in the field of polycarboxylic acid-based water-reducing agent for cement concrete, can solve the problems of small electrostatic repulsion effect and small reduction range, and achieves increased steric hindrance, reduced difficulty, Excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention proposes a preparation method of the above-mentioned mud-resistant polycarboxylate superplasticizer, the specific steps of which are as follows:

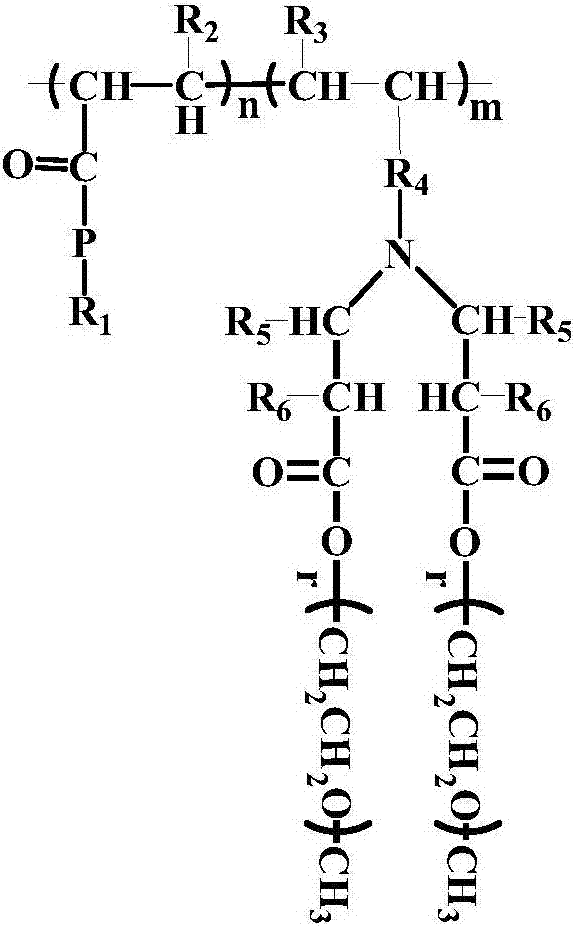

[0027] 1) Preparation of amine-terminated copolymerization products: Oxidation-reduction free radical polymerization of carbonyl-containing unsaturated small monomers and amine-terminated unsaturated small monomers at 25-45°C under the action of initiators, reducing agents and chain transfer agents React for 30-90 minutes to obtain a copolymerization product containing terminal amino groups, and the molecular structural formula of the copolymerization product containing terminal amino groups is Among them, the molecular weight is 3000-5000, and the degree of polymerization n and m are 10-100 respectively; among them, P is N, NH or O atom; R 1 It is H, alkali metal ion, alkyl group containing 1-6 carbon atoms, hydroxyalkyl group containing 1-6 carbon atoms, alkoxy group containing 1-6 carbon atoms, pheny...

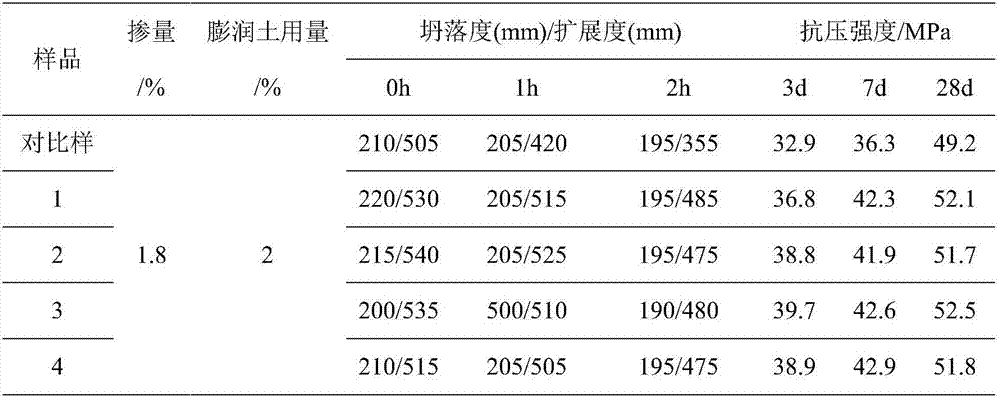

Embodiment 1

[0031] 1) Preparation of amine-terminated copolymers: 10mol acrylic acid and 10mol 2-methacrylamine were oxidized at 25°C under the action of 0.01mol hydrogen peroxide, 0.01mol molasses, and 0.01mol sodium methallylsulfonate- Reductive radical polymerization was carried out for 30 minutes to obtain a copolymer product with a molecular weight of 3000, wherein the degree of polymerization n was 40, and m was 10;

[0032] 2) Preparation of mud-resistant superplasticizer: 10 mol of amine-terminated copolymer and 2.5 mol of polyethylene glycol monomethyl ether acrylate (polymerization degree r = 9) were subjected to Michael addition reaction at 10°C for 3 hours to obtain a Anti-mud type polycarboxylate superplasticizer.

Embodiment 2

[0034] 1) Preparation of amino-terminated copolymers: 10mol methacrylic acid and 9mol acrylamine were subjected to oxidation-reduction free radical polymerization under the action of 0.02mol ammonium persulfate, 0.01mol sodium sulfite, and 0.02mol thioglycolic acid at 30°C for 35 minutes to obtain a molecular weight of 3500 The copolymerization product, wherein the degree of polymerization n is 15, m is 30;

[0035] 2) Preparation of mud-resistant superplasticizer: add 10 mol of amine-terminated copolymer to 3 mol of polyethylene glycol monomethyl ether acrylate (polymerization degree r is 18) and perform Michael addition reaction at 50°C for 0.5 h to obtain a A mud-resistant polycarboxylate superplasticizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com