Aluminum alloy anodic oxidation electrolyte solution and technology based on corrosion inhibitors

A technology of anodic oxidation and corrosion inhibitor, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of low slow release rate, high price, large dosage, etc., achieve simple process and improve corrosion resistance , easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

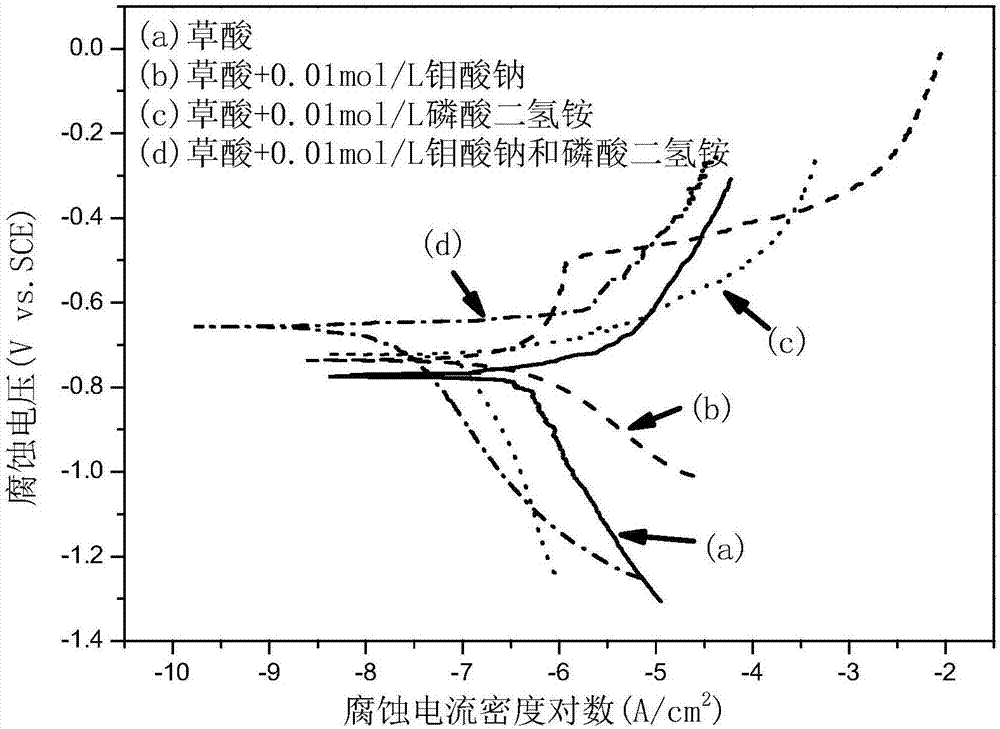

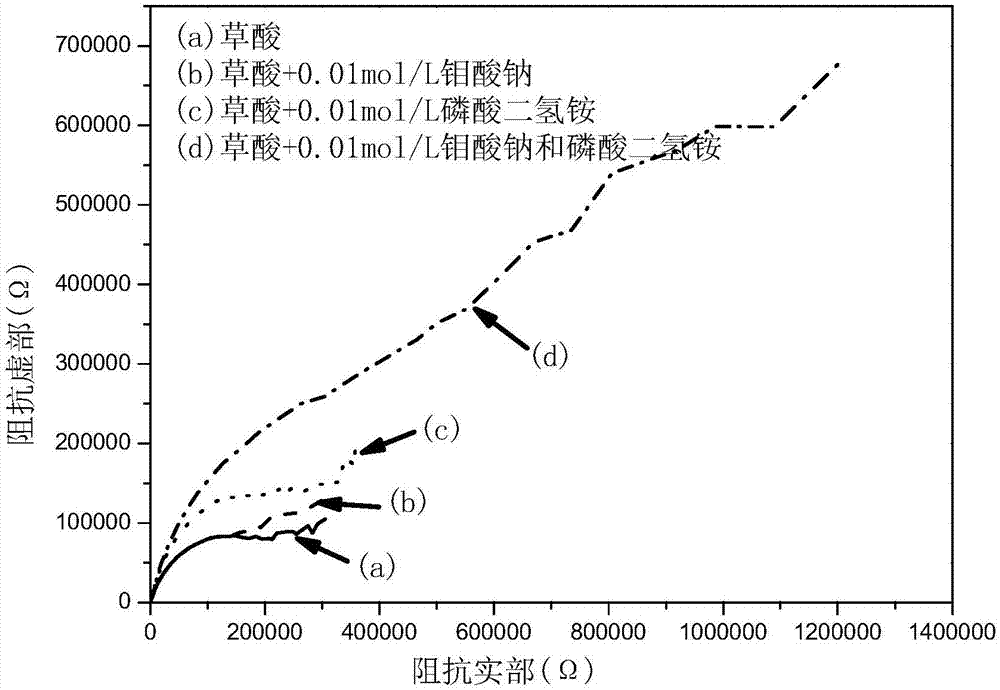

[0019] An aluminum alloy anodic oxidation electrolyte and oxidation process based on a corrosion inhibitor.

[0020] 1. The specific steps of the method

[0021] (1) Grinding treatment: Grind the aluminum alloy with 400#, 600#, 800#, 1000#, 1200# sandpaper in sequence, then put it into an ethanol solution for ultrasonic cleaning for 2 minutes, take it out, rinse it with distilled water, and dry it with cold air.

[0022] (2) Chemical degreasing: The concentration of NaOH solution is 40g / L, the temperature is about 50°C, stir with a magnetic stirrer at the same time, the speed is 1000r / min, the reaction time is 1min, then take it out and rinse it with distilled water, and dry it with cold wind.

[0023] (3) Pickling light: HNO 3 The concentration of the solution is 20g / L, stirred with a magnetic stirrer at room temperature, the rotation speed is 1000r / min, and the reaction time is 1min, then take it out, rinse it with distilled water, and dry it with cold wind.

[0024] (4) A...

Embodiment 2

[0029] An aluminum alloy anodic oxidation electrolyte and oxidation process based on a corrosion inhibitor.

[0030] The preparation method of the present embodiment is different from step (4) in (1) except that step (4) is different from embodiment 1, and all the other repeat the steps in embodiment 1, and concrete process is as follows:

[0031] (1), the specific steps of the method

[0032] (1) grinding treatment: repeat step (1) in (one) of embodiment 1;

[0033] (2) chemical degreasing: repeat step (2) in (one) of embodiment 1;

[0034] (3) Pickling to produce light: repeat step (3) in (1) of Example 1;

[0035] (4) Anodizing process: preparation of anodic oxidation electrolyte: the concentration of oxalic acid in the anodic oxidation electrolyte is 40g / L, then add 0.05mol / L sodium molybdate and 0.05mol / L ammonium dihydrogen phosphate to oxalic acid; anodic oxidation conditions : The anodizing temperature is 20°C, the anodizing voltage is 45V, and the reaction time is ...

Embodiment 3

[0040] An aluminum alloy anodic oxidation electrolyte and oxidation process based on a corrosion inhibitor.

[0041] The preparation method of the present embodiment is different from step (4) in (1) except that step (4) is different from embodiment 1, all the other repeat the steps in embodiment 1, and concrete process is as follows:

[0042] (1), the specific steps of the method

[0043] (1) grinding treatment: repeat step (1) in (one) of embodiment 1;

[0044] (2) chemical degreasing: repeat step (2) in (one) of embodiment 1;

[0045] (3) Pickling to produce light: repeat step (3) in (1) of Example 1;

[0046] (4) Anodizing process: prepare anodic oxidation electrolyte: the concentration of oxalic acid in the anodic oxidation electrolyte is 40g / L, then add 0.02mol / L sodium molybdate and 0.02mol / L ammonium dihydrogen phosphate to oxalic acid; anodic oxidation conditions : The anodizing temperature is 18°C, the anodizing voltage is 50V, and the reaction time is 90min. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com