Optimized diesel hydrocracking catalyst and preparation method thereof

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems that the catalyst is difficult to exert the best performance, the product quality of middle distillate oil is average, and the catalytic activity of the catalyst is not high. , to achieve the effects of fast transfer, guaranteed diesel yield and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

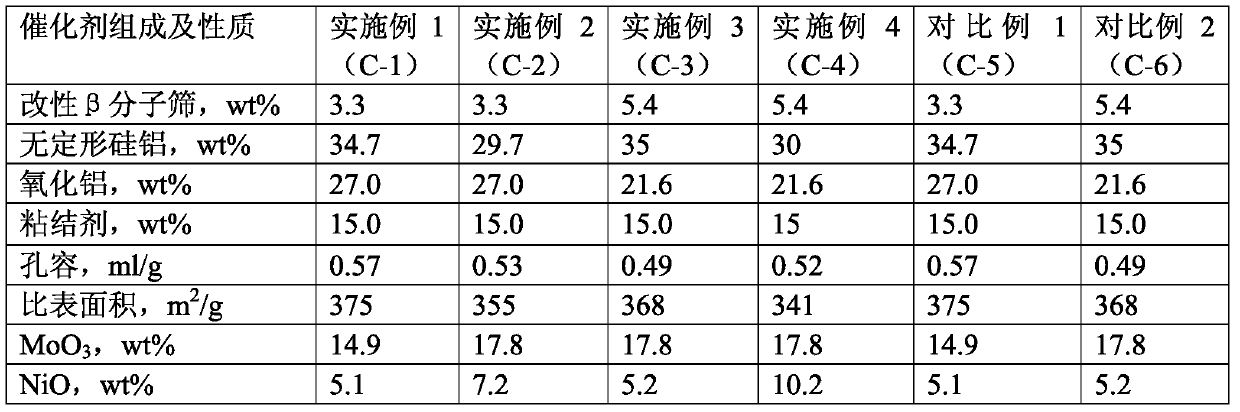

Embodiment 1

[0036] Take by weighing 201.3g tetraethylammonium bromide (technical grade), 27.39g sodium hydroxide, 7.2g pseudo-boehmite (70wt%, technical grade), 870g water mix and stir to clear solution, then under constant stirring Add 180g of white carbon black (industrial grade) to the solution, and continue to stir to obtain a uniform silica-alumina gel; the silica-alumina gel was dynamically crystallized at 145°C for 7 days, and after solid-liquid separation, washing and drying, it was placed in the air Roast at 550°C in stream for 8 hours to obtain β molecular sieve. After the template is removed, ammonium exchange is carried out twice at 80°C with a concentration of 0.5mol / L ammonium chloride solution. The liquid-solid ratio is 10:1. After washing and drying, Carry out hydrothermal treatment again, under water vapor pressure 0.15MPa, treatment temperature is 600 ℃, treatment time is 2.5 hours, carry out aluminum salt treatment afterwards, put the molecular sieve after hydrothermal t...

Embodiment 2

[0039] Modified molecular sieve is the same as the β modified molecular sieve in embodiment 1; Molecular sieve and γ-Al 2 o 3 Composite material is the same as embodiment 1; Composite material 195.5g (dry basis 93%), amorphous silicon aluminum 204.5g (dry basis 88%), MoO 3 108.5g (99.1wt%), Ni(NO 3 ) 2 ·6H 2 O (NiO, 26.6wt%) was mixed with 163.4g and 360g of binder (25% on a dry basis), and rolled in a wheel mill for 40 minutes to form an extrudable paste, extruded into strips, and shaped as Columnar shape with a length of 3-8nm, dried at 120°C for 20 hours, and calcined at 500°C for 5-6 hours to obtain a hydrocracking catalyst, numbered C-2, and its properties are shown in Table 2.

Embodiment 3

[0041] The modified molecular sieve is the same as the β modified molecular sieve in Example 1; 140g ammonium oxalate is weighed and mixed with 3000ml aluminum chloride solution (concentration is 1.5mol / L) in a 5000ml beaker, and 52.6g (dry basis 98%) is modified Molecular sieves were added to the mixture, kept at a constant temperature of 70°C, continuously added 2mol / L ammonia water until the pH value was 4, evaporated at 85°C, dried at 100°C for 3 hours, and roasted at 500°C for 4 hours to obtain molecular sieves γ-Al 2 o 3 Composite material 272.8g (dry basis 93%), conversion rate 72.3%. Molecular sieve and γ-Al 2 o 3 Composite material 173.2g (dry basis 93%), amorphous silicon aluminum 238.6g (dry basis 88%), MoO 3 108.5g (99.1wt%), Ni(NO 3 ) 2 ·6H 2 O (NiO, 26.6wt%) was mixed with 116.7g and 360g of binder (25% on a dry basis), and rolled in a wheel mill for 40 minutes to form an extrudable paste, extruded into strips, and shaped as Columnar shape with a length o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com