Preparation method of catalyst in preparation of dimethyl ether by methyl alcohol

A methanol preparation and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor low temperature activity, low reaction temperature, high energy consumption, and achieve low equipment corrosion and catalytic activity. The effect of high and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

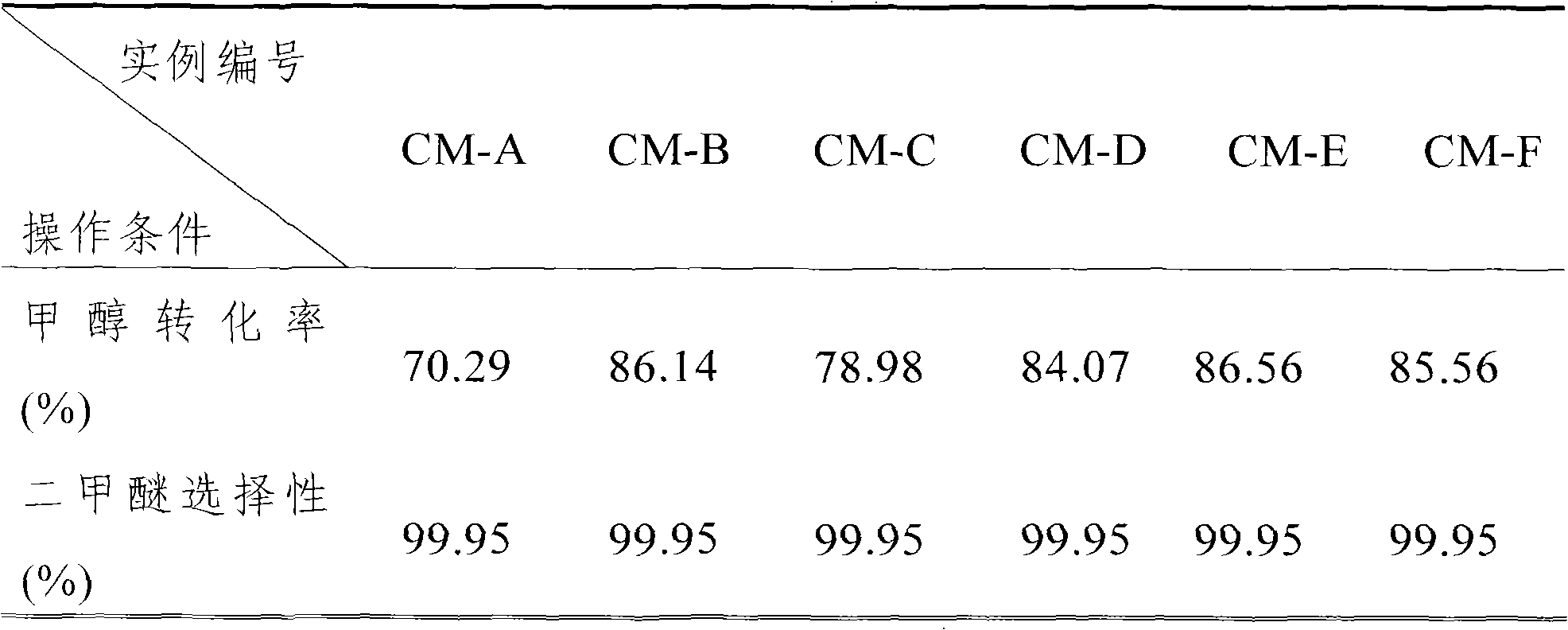

Embodiment 1

[0016] Fully mix 280 grams of pseudo-boehmite powder, 210 grams of pseudo-boehmite powder roasted at 500°C, 23 grams of HZSM-5 molecular sieve, 7.5 grams of squash powder and 7.5 grams of chemical paste, then add 10 grams of citric acid and 50ml of self-made aluminum sol is uniformly mixed and rolled in a kneader to form a lump material, and finally the lump material is extruded into a strip-shaped material in an extruder; the strip-shaped material is first dried at room temperature, and then Dry in an oven for 8-12 hours, and finally bake in a muffle furnace, in an air atmosphere, bake at 150°C for 5 hours, at 300°C for 2 hours, at 400°C for 1 hour, at 500°C for 5 hours, cool to room temperature, and cool to At room temperature, the catalyst for preparing dimethyl ether from methanol is obtained, and the sample number is CM-A.

Embodiment 2

[0018] Fully mix 280 grams of pseudo-boehmite powder, 210 grams of pseudo-boehmite powder roasted at 400°C, 75 grams of HZSM-5 molecular sieve, 7.5 grams of squash powder, and 7.5 grams of chemical paste, then add 10 grams of citric acid and 50ml of self-made aluminum sol is uniformly mixed and rolled in a kneader to form a lump material, and finally the lump material is extruded into a strip-shaped material in an extruder; the strip-shaped material is first dried at room temperature, and then Dry in an oven for 8-12 hours, and finally bake in a muffle furnace, in an air atmosphere, bake at 200°C for 1.5 hours, at 300°C for 1.5 hours, at 400°C for 2 hours, at 500°C for 4 hours, cool to room temperature, and cool to At room temperature, the catalyst for preparing dimethyl ether from methanol is obtained, and the sample number is CM-B.

Embodiment 3

[0020] Fully mix 120 grams of pseudo-boehmite powder, 5 grams of HZSM-5 molecular sieve, 5 grams of titanium sulfate and 3 grams of chemical paste, and uniformly mix and roll in a kneader to form a lump material, and finally the lump material Extrude into a strip-shaped material in the extruder; first dry the strip-shaped material at room temperature, then dry it in an oven for 8-12 hours, and finally roast it in a muffle furnace, and roast it at 200 ° C for 2 hours in an air atmosphere. Calcined at 300°C for 2 hours, 400°C for 1.5 hours, 550°C for 1 hour, cooled to room temperature, and then cooled to room temperature to obtain a catalyst for preparing dimethyl ether from methanol. The sample number is CM-C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com