Preparation method for L-oxiracetam oral membrane

An oral film and plasticizer technology, which is used in aerosol delivery, nervous system diseases, liquid delivery, etc., can solve the complex development and production process, complex liposome preparation process, and solid particle agglomeration. problems, to achieve the effect of improving bioavailability, avoiding elimination effects, and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

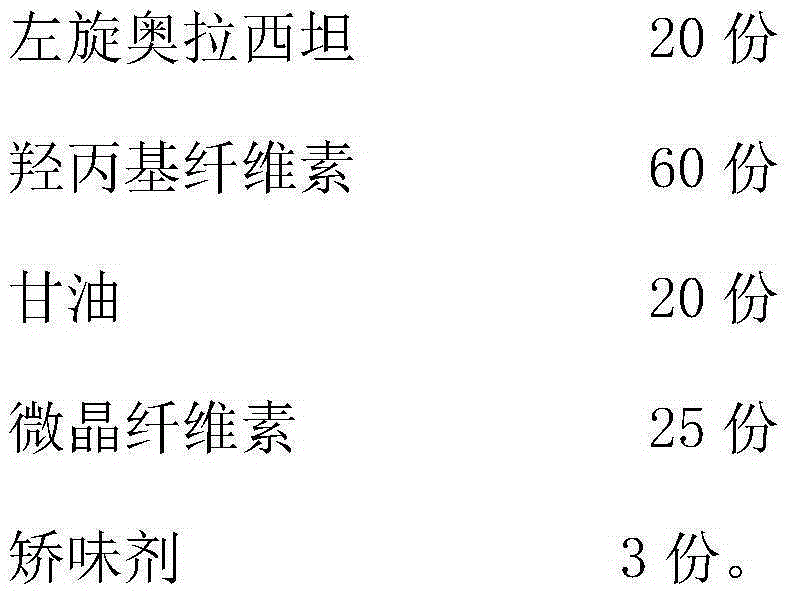

[0046] A preparation method of levoxiracetam oral film, adopts following steps:

[0047] 1) Dissolve 40-65 parts of hydroxypropyl cellulose in absolute ethanol to form a homogeneous viscous liquid, then add 10-25 parts of glycerin and mix well to form material I;

[0048] 2) Mix 1-20 parts of levoxiracetam, 5-30 parts of filler and 1-3 parts of flavoring agent, and disperse with absolute ethanol to form material II;

[0049] 3) Mix material II with material I, and stir at a stirring rate of 500r / min to 800r / min for 60min to 120min to form levoxiracetam suspension without bubbles;

[0050] 4) Cast the levo-oxiracetam bubble-free suspension viscous liquid prepared in step 3) on a mold, dry at 55-90°C, cool at room temperature, form a film, and cut to obtain the levo-oxiracetam oral film agent.

Embodiment 2

[0052] A preparation method of levoxiracetam oral film, adopts following steps:

[0053] 1) Dissolve 35-60 parts of pullulan in absolute ethanol to form a homogeneous viscous liquid, then add 15-30 parts of propylene glycol and mix to form material I;

[0054] 2) Mix 1-20 parts of levoxiracetam, 5-30 parts of filler and 2-4 parts of flavoring agent, and disperse with absolute ethanol to form material II;

[0055] 3) Mix material II with material I, and stir for 70-130 min at a stirring rate of 500r / min to 700r / min to form levoxiracetam suspension viscous liquid without bubbles;

[0056] 4) Cast the levo-oxiracetam bubble-free suspension viscous liquid prepared in step 3) on a mold, dry at 45-85°C, cool at room temperature, form a film, and cut to obtain the levo-oxiracetam oral film agent.

Embodiment 3

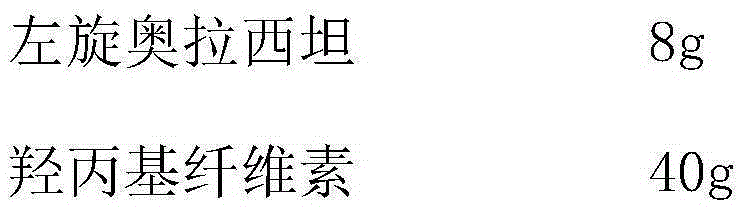

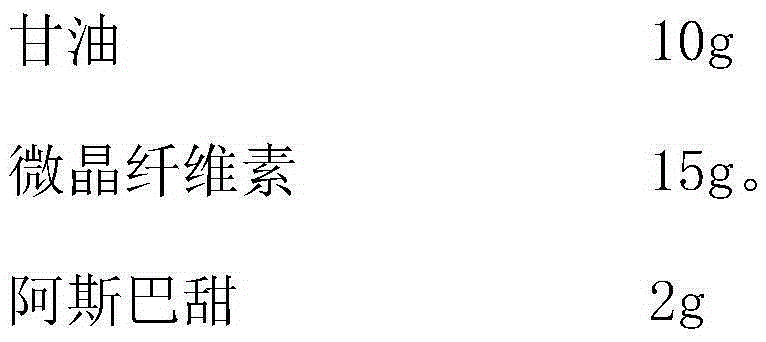

[0058]

[0059] 1) Dissolving hydroxypropyl cellulose in absolute ethanol to form a homogeneous viscous liquid, then adding glycerin and mixing to form material I;

[0060] 2) Mix levoxiracetam, microcrystalline cellulose and flavoring agent evenly, and disperse with absolute ethanol to form material II;

[0061] 3) Mix the material II with the material I, stir, the stirring rate is 500r / min~600r / min, and the stirring time is 80min~90min, forming levoxiracetam suspension viscous liquid without bubbles;

[0062] 4) Cast the levo-oxiracetam non-bubble suspension viscous liquid prepared in step 3) on a mold, dry at 72-75°C, cool at room temperature, form a film, and cut to obtain the levo-oxiracetam oral film agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| optical rotation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com