A kind of preparation method of nano silver polyhedron quasi-sphere

A polyhedral, nano-silver technology, applied in the field of precious metal silver nanomaterials, can solve the problems of inability to control the shape and size of nano-silver particles, the mixed shape of the final product of nano-silver particles, and hindering commercial applications, and achieve localized surface plasmon. The resonance absorption spectrum has strong controllability, good monodispersity, and the effect of a wide range of particle size control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

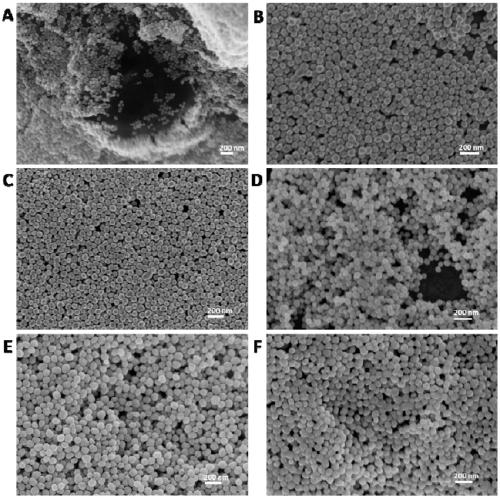

[0026] Embodiment 1: prepare 48.7nm nano-silver polyhedron quasi-sphere

[0027] Before using the ethylene glycol reagent, dry it continuously at 105-110°C for more than 1 hour to remove water, and add 0.03M AgNO 3 , 5mM Ni(NO 3 ) 2 ·6H 2 O and 0.14M, Mw=30000 polyvinylpyrrolidone were added to 100mL of ethylene glycol solvent in order to remove water, sealed with plastic wrap and stirred vigorously for 0.5-1h, then slowly stirred for 5-10min to fully dissolve. Remove the plastic wrap, open the container, and irradiate the above solution with a microwave oven with a frequency of 2450MHz at a power of 300-1000W at 140-165°C for 3 minutes, stop for 2-3 minutes and then irradiate with microwaves for 1 minute. After the reaction is completed, place it at room temperature and cool it to room temperature , add deionized water to dilute 2-5 times, stir for 10-20min, centrifuge at 3000-8000rpm after ultrasonication for 5-10min, remove the supernatant, and wash the bottom colloid th...

Embodiment 2

[0028] Embodiment 2: prepare 65.8nm nano-silver polyhedron quasi-sphere

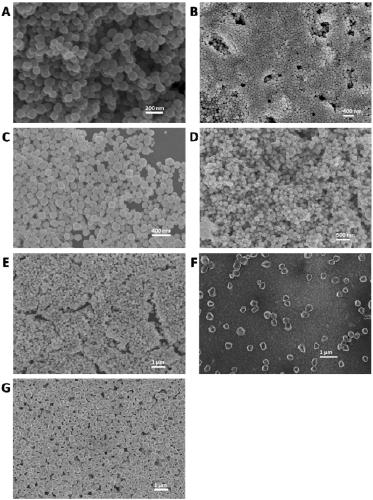

[0029] Referring to Example 1, the difference is that: polyvinylpyrrolidone is reduced to 0.09M, and the microwave irradiation time is 4min, and product B can be produced, and the quasi-sphere diameter of the nano-silver polyhedron is 65.8 ± 3.7nm, and its scanning electron microscope (SEM) figure, see figure 1 In B, the product has regular shape and uniform size, and the shape and size can be adjusted. X-ray diffraction (XRD) pattern see Figure 4 , UV-visible-near-infrared light absorption spectrum see Figure 5 In B, the transmission electron microscope-energy spectrum (TEM-EDS) of product of the present invention sees Image 6 .

Embodiment 3

[0032] Embodiment 3: prepare 75.8nm nano-silver polyhedron quasi-sphere

[0033] With reference to Example 1, the difference is that: the microwave irradiation time is 4-5min, product C can be obtained, and the quasi-sphere diameter of the nano-silver polyhedron is 75.8 ± 4.2nm, and its scanning electron microscope (SEM) figure is shown in figure 1 Middle C, X-ray diffraction (XRD) pattern see Figure 4 , UV-visible-near-infrared light absorption spectrum see Figure 5 In C, the transmission electron microscope-energy spectrum (TEM-EDS) of product of the present invention sees Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com