Method for improving comprehensive performance of lead alloy rolling anode

A comprehensive performance, lead alloy technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of lack of corrosion center on the surface of anode material, deterioration of mechanical properties of Pb-based alloy, and unsatisfactory metallographic phase of anode plate alloy, etc. Corrosion resistance and electrochemical catalytic performance, improving electrocatalytic activity, and the effect of good electrochemical catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

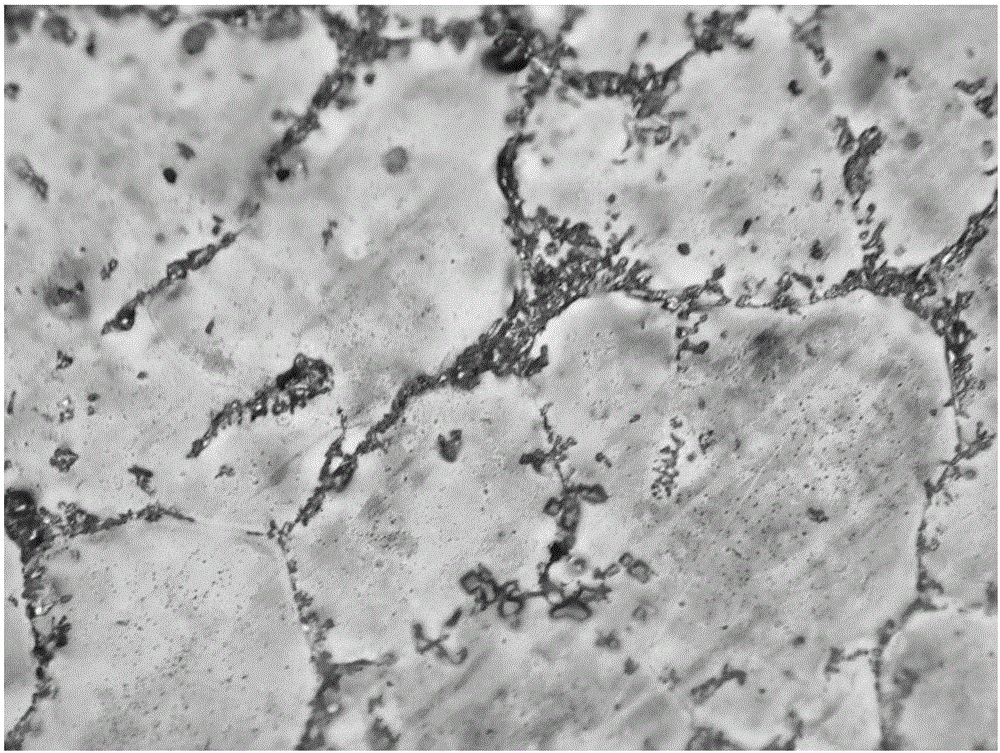

Image

Examples

Embodiment 1

[0035] In this embodiment, the as-cast lead-based alloy is a Pb-Ag-RE alloy, in terms of mass percentage: Ag=0.3%, Nd=0.08%, and the balance is Pb;

[0036] (1) Cast lead alloy in a resistance furnace according to conventional methods, and the original size of the alloy is 8cm×10cm×12cm;

[0037] (2) Calendering: the Pb alloy obtained in step (1) is rolled by a rolling mill, the rolling temperature is room temperature, and the reduction is 90%, and lubricating liquid is added during the rolling process to lubricate and avoid overheating. After rolling, carry out 42h static aging treatment.

[0038] (3) Surface heat treatment: Heating in a protective atmosphere furnace, the anode plate obtained in step (2) is placed in the furnace, and under an inert protective atmosphere, the temperature is raised to 270°C at a heating rate of 20°C / s, kept for 60s, and then water-cooled to room temperature;

[0039] (4) In the zinc electrodeposition system (Zn 2+ 50g / L, H 2 SO 4 160g / L, ...

Embodiment 2

[0042] In this embodiment, the as-cast lead-based alloy is a Pb-Ag alloy, in terms of mass percentage; Ag=0.5%, and the balance is Pb;

[0043] (1) Cast lead alloy in a resistance furnace according to conventional methods, and the original size of the alloy is 8cm×10cm×12cm;

[0044] (2) Calendering: the Pb alloy obtained in step (1) is rolled by a rolling mill, the rolling temperature is room temperature, and the reduction is 75%, and lubricating liquid is added during the rolling process to lubricate and avoid overheating. After rolling, carry out 24h static aging treatment;

[0045] (3) Surface heat treatment: the anode plate obtained in step (2) is placed in a salt bath with a temperature of 200° C., kept for 135 s, and then cooled to room temperature by water cooling;

[0046] (4) In the zinc electrodeposition system (Zn 2+ 50g / L, H 2 SO 4 160g / L, temperature 40℃), the tensile strength is 20.7MPa, the cell voltage is 1.634V, and the corrosion rate is 3.6g / m 2 h; Com...

Embodiment 3

[0048] In this embodiment, the as-cast lead-based alloy is a Pb-Ag alloy, in terms of mass percentage; Ag=0.8%, and the balance is Pb;

[0049] (1) Cast lead alloy in a resistance furnace according to conventional methods, and the original size of the alloy is 8cm×10cm×12cm;

[0050] (2) Calendering: the Pb alloy obtained in step (1) is rolled by a rolling mill, the rolling temperature is room temperature, and the reduction is 80%, and lubricating liquid is added during the rolling process to lubricate and avoid overheating. Carry out 30h static aging treatment after calendering;

[0051] (3) Surface heat treatment: place the anode plate obtained in step (2) in an intermediate frequency heating coil and heat it until the surface temperature of the anode reaches 220°C, hold the temperature for 6 seconds, and then cool it to room temperature by water cooling;

[0052] (4) In the zinc electrodeposition system (Zn 2+ 50g / L, H 2 SO 4 160g / L, temperature 40℃), the tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com