A kind of environment-friendly foam concrete for architectural decoration engineering

A technology for building decoration engineering and foam concrete, applied in the field of building decoration engineering, can solve the problems of poor stability of foaming agent, poor stability of slurry, easy water absorption and toughness, etc., and achieve significant economic and social benefits, storage resistance, foam rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

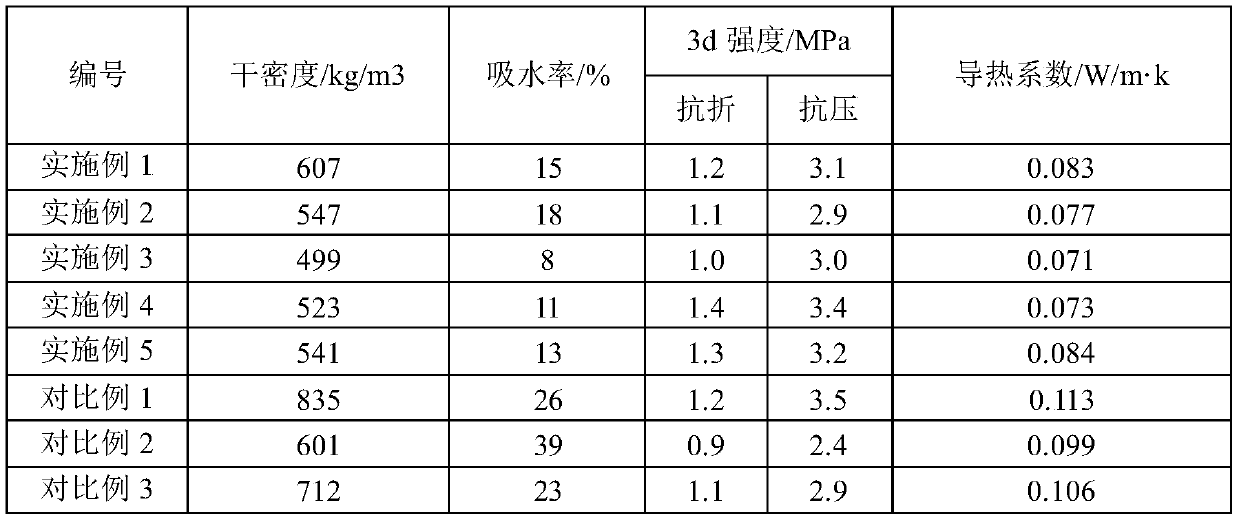

Examples

Embodiment 1

[0032] An environment-friendly foam concrete for building decoration engineering comprises the following components in parts by mass:

[0033] Cement: 35%

[0034] Ceramic tile polishing powder: 3%

[0035] Rosin type foaming agent: 1%

[0036] Foam-increasing and foam-stabilizing components: 0.05%

[0037] Aluminum carbonate: 0.5%

[0039] Enhancer: 0.5%

[0040] Silicone water repellent: 0.5%

[0041] The balance is water.

[0042] Described rosin type whipping agent preparation method is as follows:

[0043] (1) Heat the rosin to 180°C to melt, keep it warm at this temperature for 20 minutes to volatilize impurities such as turpentine, then cool, crush the cooled rosin, and pass it through a 100-mesh sieve for later use.

[0044] (2) Mix sodium hydroxide and water at a mass ratio of 1:2 and heat to boiling, then put rosin powder, sodium alginate, and tall oil into the reaction kettle at a mass ratio of 6:3:1, and stir until completely mel...

Embodiment 2

[0050] An environment-friendly foam concrete for building decoration engineering comprises the following components in parts by mass:

[0051] Cement 55%

[0052] Ceramic tile polishing powder 8%

[0053] Rosin type foaming agent 4%

[0054] Foam-increasing and foam-stabilizing components 0.1%

[0055] Aluminum Carbonate 1%

[0057] Enhancer 2%

[0058] Silicone Water Repellent 2%

[0059] The balance is water.

[0060] Described rosin type whipping agent preparation method is as follows:

[0061] (1) Heat the rosin to 220°C to melt, keep it warm at this temperature for 30 minutes to fully volatilize impurities such as turpentine, then cool, crush the cooled rosin, and pass it through a 100-mesh sieve for later use.

[0062] (2) Mix sodium hydroxide and water at a mass ratio of 1:2 and heat to boiling, then put rosin powder, sodium alginate, and tall oil into the reaction kettle at a mass ratio of 9:1:1, and stir until completely melted , co...

Embodiment 3

[0068] An environment-friendly foam concrete for building decoration engineering comprises the following components in parts by mass:

[0069]Cement: 40%

[0070] Ceramic tile polishing powder: 5%

[0071] Rosin foaming agent: 3%

[0072] Foam-increasing and foam-stabilizing components: 0.08%

[0073] Aluminum carbonate: 0.8%

[0075] Enhancer: 1%

[0076] Silicone water repellent: 1%

[0077] The balance is water.

[0078] The cement refers to rapid hardening Portland cement.

[0079] The ceramic tile polishing powder refers to powder waste with a certain fineness produced during a series of deep processing of ceramic polishing tiles such as scraping and thickness determination, grinding and polishing, and edge grinding and chamfering.

[0080] Described rosin type whipping agent preparation method is as follows:

[0081] (1) Heat the rosin to 200°C to melt, keep it warm at this temperature for 25 minutes to volatilize impurities such as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com