Indoor expansive type fireproof steel structure coating and preparation method thereof

An intumescent technology for steel structure coatings, applied in the direction of fire-proof coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., to achieve the effects of enhanced corrosion resistance, slow degradation speed, and improved degradation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

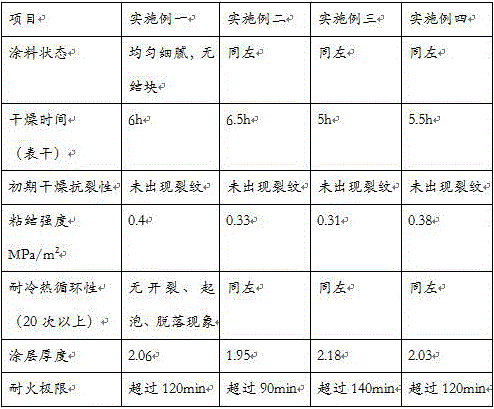

Examples

Embodiment 1

[0026] An indoor intumescent fireproof steel structure coating, the fireproof coating is composed of the following raw materials: polyvinyl acetate emulsion 50g / kg, titanium dioxide 1.3g / kg, polyaziridine crosslinking agent 1.6 g / kg, polyacrylic acid 0.8g / kg, aluminum silicate fiber 4g / kg, aluminum hydroxide 3g / kg, boron nitride powder 2g / kg, neodymium oxide composite zirconia ceramic powder 8g / kg, glycerol bisphosphate melamine salt 16g / kg , foaming agent 4g / kg, modified silicone hydrophobic agent 0.3 g / kg, paint film antifungal agent 0.7g / kg, dehydration catalyst 9g / kg, carbonizing agent 3.7g / kg, the balance is distilled water or deionized water .

[0027] In the above formula, the softening point of polyvinyl acetate emulsion is very low, between 110°C and 120°C, the coating is already in a softened and molten state before the flame retardant starts to decompose, so it will not affect the foaming of the flame retardant The expansion produces retardation, and the polyvinyl ...

Embodiment 2

[0040] Embodiment two is the same as embodiment one, and its difference is that, the preparation method of indoor expansion type fireproof steel structure coating comprises the following steps:

[0041] Step 1. Prepare materials according to the ratio of each component. Polyvinyl acetate emulsion SD-40 is 40g / kg, 200 mesh titanium dioxide is 1g / kg, polyethylenimine crosslinking agent TS280 is 1g / kg, polyacrylic acid TH-1100: 0.5 g / kg, aluminum silicate fiber 3g / kg, 200 mesh aluminum hydroxide powder 6g / kg, 200 mesh boron nitride powder 3g / kg, 150 mesh Nd 2 Zr 2 0 7 Ceramic powder 6g / kg, glycerol diphosphate melamine salt 10g / kg, melamine YT07-2006 3g / kg, modified silicone hydrophobic agent 0.2g / kg, iodopropynyl carbamate paint film anti Mold agent 0.5g / kg, ammonium polyphosphate 6g / kg, pentaerythritol YT09-2002 3g / kg, the balance is deionized water;

[0042] Step 2. Put the proportioned polyvinyl acetate emulsion SD-40 in a container, add polyethylenimine crosslinking agent...

Embodiment 3

[0047] Embodiment three is the same as embodiment two and embodiment one, and its difference is that, the preparation method of indoor expansion type fireproof steel structure coating comprises the following steps:

[0048] Step 1. Prepare materials according to the ratio of each component, polyvinyl acetate emulsion SD-40 is 60g / kg, 200 mesh titanium dioxide is 1g / kg, polyethylenimine crosslinking agent TS280 is 2g / kg, polyacrylic acid TH-1100: 1.0g / kg, aluminum silicate fiber 6g / kg, 200 mesh aluminum hydroxide powder 4g / kg, 200 mesh boron nitride powder 3g / kg, 150 mesh Nd 2 Zr 2 0 7 Ceramic powder 6g / kg, glycerol diphosphate melamine salt 20g / kg, melamine YT07-2006 5g / kg, modified silicone hydrophobic agent 0.5g / kg, iodopropynyl carbamate paint film anti Mold agent 1g / kg, ammonium polyphosphate 12g / kg, pentaerythritol YT09-2002 4g / kg, the balance is deionized water;

[0049] Step 2. Put the proportioned polyvinyl acetate emulsion SD-40 in a container, add polyethylenimine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com