Method for preparing conductive composite nanofiber nervous tissue engineering scaffold based on graphene

A technology of composite nanofibers and nerve tissue, applied in the direction of fiber type, fiber processing, animal fiber, etc., to achieve the effect of good biocompatibility, improved biological activity, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method based on graphene conductive composite nanofiber neural tissue engineering scaffold, the specific steps are:

[0045] 1. Place the tussah silk at 95~100℃ 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

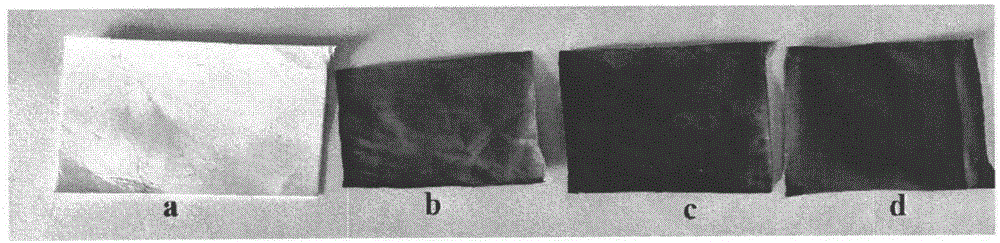

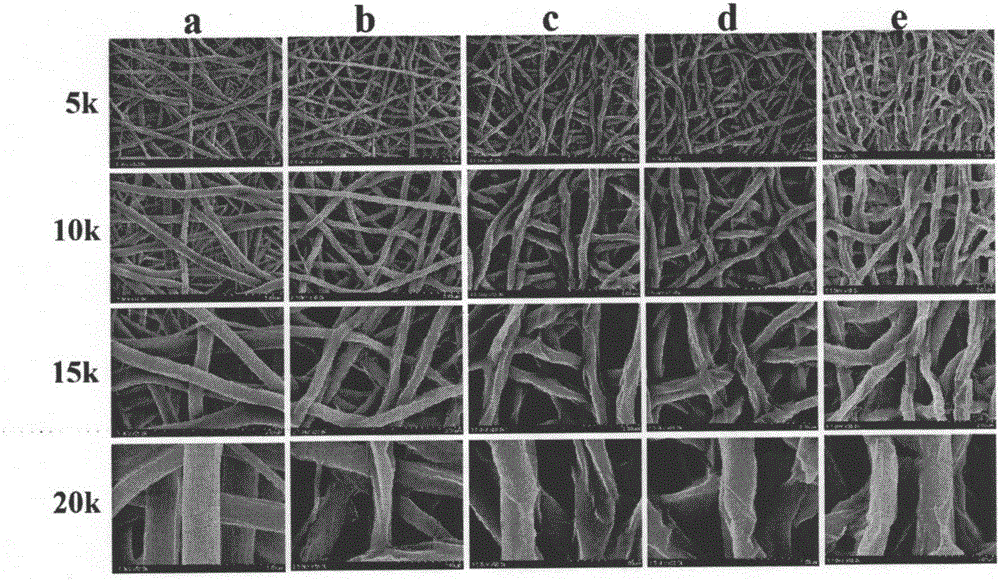

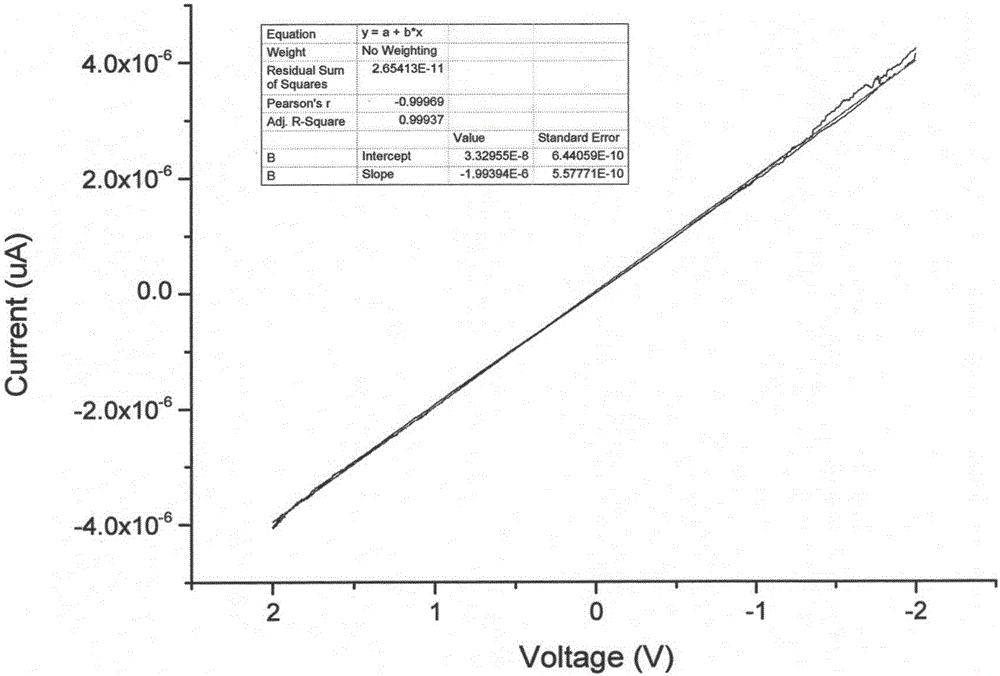

[0046] 2. Weigh 0.25g of tussah silk fibroin protein, 0.75g of polylactic acid-polycaprolactone, dissolve in 10ml of hexafluoroisopropanol, and magnetically stir at a certain speed until completely dissolved, and the obtained concentration is 10% (w / v ) spinning solution. Condu...

Embodiment 2

[0049] A preparation method based on graphene conductive composite nanofiber neural tissue engineering scaffold, the specific steps are:

[0050] 1. Place the tussah silk at 95~100℃ 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

[0051] 2. Weigh 0.25g of tussah silk fibroin protein, 0.75g of polylactic acid-polycaprolactone, dissolve in 10ml of hexafluoroisopropanol, and magnetically stir at a certain speed until completely dissolved, and the obtained concentration is 10% (w / v ) spinning solution. Condu...

Embodiment 3

[0054] A preparation method based on graphene conductive composite nanofiber neural tissue engineering scaffold, the specific steps are:

[0055] 1. Put the tussah silk in the environment of 95~100℃, 2 CO 3 The degumming solution was degummed 3 times, each time for 30 minutes, and the bath ratio was 1:50. After degumming, the tussah silk fibers are obtained and dried at 60°C. Put the tussah silk fibroin fiber in a saturated LiSCN solution at a bath ratio of 1:10, dissolve it for 70 minutes at 50°C±2°C, put the obtained tussah silk fibroin protein solution into a dialysis bag with a molecular weight cut-off of 8-10KDa, and use Dialyzed with deionized water for 3 days, and freeze-dried to obtain tussah silk fibroin.

[0056] 2. Weigh 0.25g of tussah silk fibroin protein, 0.75g of polylactic acid-polycaprolactone, dissolve in 10ml of hexafluoroisopropanol, and magnetically stir at a certain speed until completely dissolved, and the obtained concentration is 10% (w / v ) spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com