Waterborne polyurethane gloves slurry, preparation method thereof, and waterborne polyurethane gloves prepared from the same

A water-based polyurethane and polyurethane prepolymer technology, applied in gloves, clothing, protective clothing, etc., can solve the problems of unable to fully meet production needs, increase the production process of gloves, slow molding and drying speed, etc., to simplify the assembly line process. Process, high tear strength, fast drying and forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

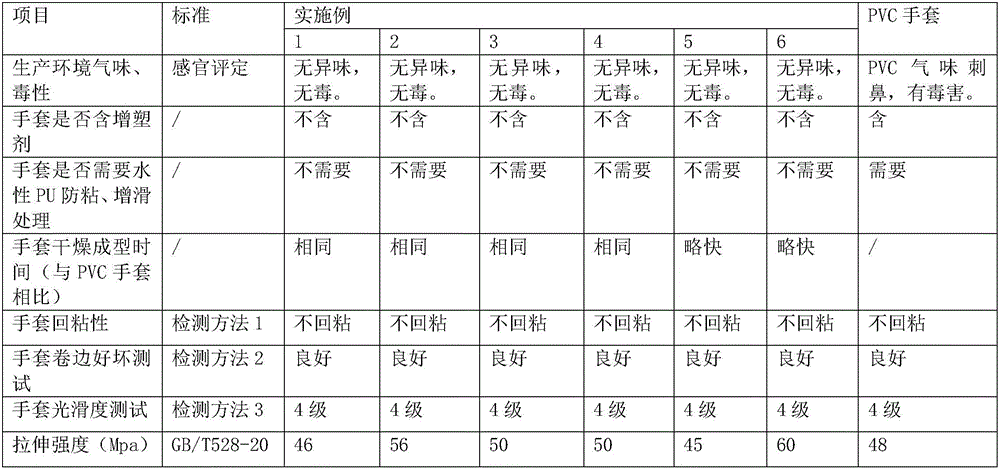

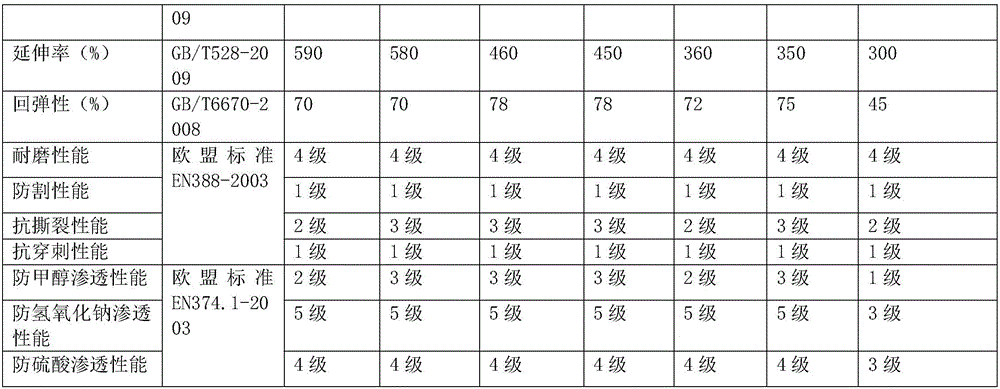

Examples

Embodiment 1

[0055] Taking the production of about 640㎏ water-based polyurethane glove slurry as an example, the lower limit value of isocyanate is used for the ratio of raw materials, and polyether glycol 4000, TDI, dimethylolpropionic acid / sulfamate chain extender A- 95, 1.6-hexanediol, stannous octoate, acetone, triethylamine, hexamethylenediamine, KH-450, organic matting powder, wetting agent W-19, leveling agent W-461, defoamer 3062, dispersion Agent W-511, Silicone Slip Agent DC-51, Wax Emulsion E-389, Hydroxyethyl Cellulose Lower Varieties.

[0056] Raw material components and formula: epoxy soybean oil B-22: 4.9kg, polyether glycol 4000: 239.7kg, TDI: 40kg, dimethylolpropionic acid / sulfamate chain extender A-95: 9.0 / 2.4kg, 1.6-hexanediol: 4kg, stannous octoate: 0.028kg, antioxidant 1010: 0.6kg, acetone: 60kg, water: 300kg, triethylamine: 6.8kg, hexamethylenediamine: 1.5kg, KH-450: 3.6kg, organic matting powder: 13kg, wetting agent W-19: 1.2kg, leveling agent W-461: 1.2kg, defoamer...

Embodiment 2

[0070] Taking the production of about 640 kg of water-based polyurethane glove slurry as an example, the raw material formula ratio adopts the lower limit of isocyanate, using polyether diol 3000 / polytetrahydrofuran diol 3000, IPDI, dimethylol butyric acid / sulfamic acid Acid acid chain extender A-95, 1.6-hexanediol, stannous octoate, N, N-diethylacetamide, triethylamine, ethylenediamine, KH-450, fumed silica, wetting agent W -518, leveling agent W-461, defoamer 3062, dispersant W-511, silicone slip agent 3667, wax emulsion E-612, associative water-based polyurethane thickener lower-level varieties.

[0071] Raw material components and formula: epoxy soybean oil B-22: 7kg, polyether diol 3000 / polytetrahydrofuran diol 3000: 113.8 / 113.9kg, IPDI: 51kg, dimethylolbutyric acid / sulfamic acid Acid acid chain extender A-95: 9.9 / 2.4kg, 1.6-hexanediol: 2.0kg, stannous octoate: 0.056kg, antioxidant 1010: 0.6kg, N, N-diethylacetamide: 36kg , Water: 264㎏, Triethylamine: 6.8㎏, Ethylenediami...

Embodiment 3

[0083] Taking the production of about 645 kg of water-based polyurethane glove slurry as an example, the raw material formula ratio adopts the intermediate value of isocyanate, using polyether diol 3000 / polycarbonate diol 3000, IPDI / HDI, dimethylol butyric acid / Small molecule sulfonate diol dispersion BY-3306B, 1.5-pentanediol, dibutyltin dilaurate, propylene glycol carbonate, dimethylaminoethanol, isophorone diamine, KH-566, nano calcium carbonate / organic Matting powder, wetting agent 245, leveling agent 410, defoamer 3062, dispersant W-9700, silicone slip agent 8427, wax emulsion E-623, alkali-swellable acrylic thickener lower-level varieties.

[0084] Raw material components and formula: epoxy soybean oil B-22: 6.6kg, polyether diol 3000 / polytetrahydrofuran diol 3000: 107.6 / 107.7kg, IPDI / HDI: 51 / 4.5kg, dimethylolbutyl Acid / small molecule sulfonate diol dispersion BY-3306B: 10.6 / 10kg, 1.5-pentanediol: 2.0kg, dibutyltin dilaurate: 0.04kg, antioxidant 1010: 0.8kg, propylene g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com