A kind of nano-ceramic thermal insulation material

A technology of heat insulation and nano-ceramics, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of cumbersome use process, poor coating performance, and low toughness of materials, and achieve large performance improvement and compatibility Good performance and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

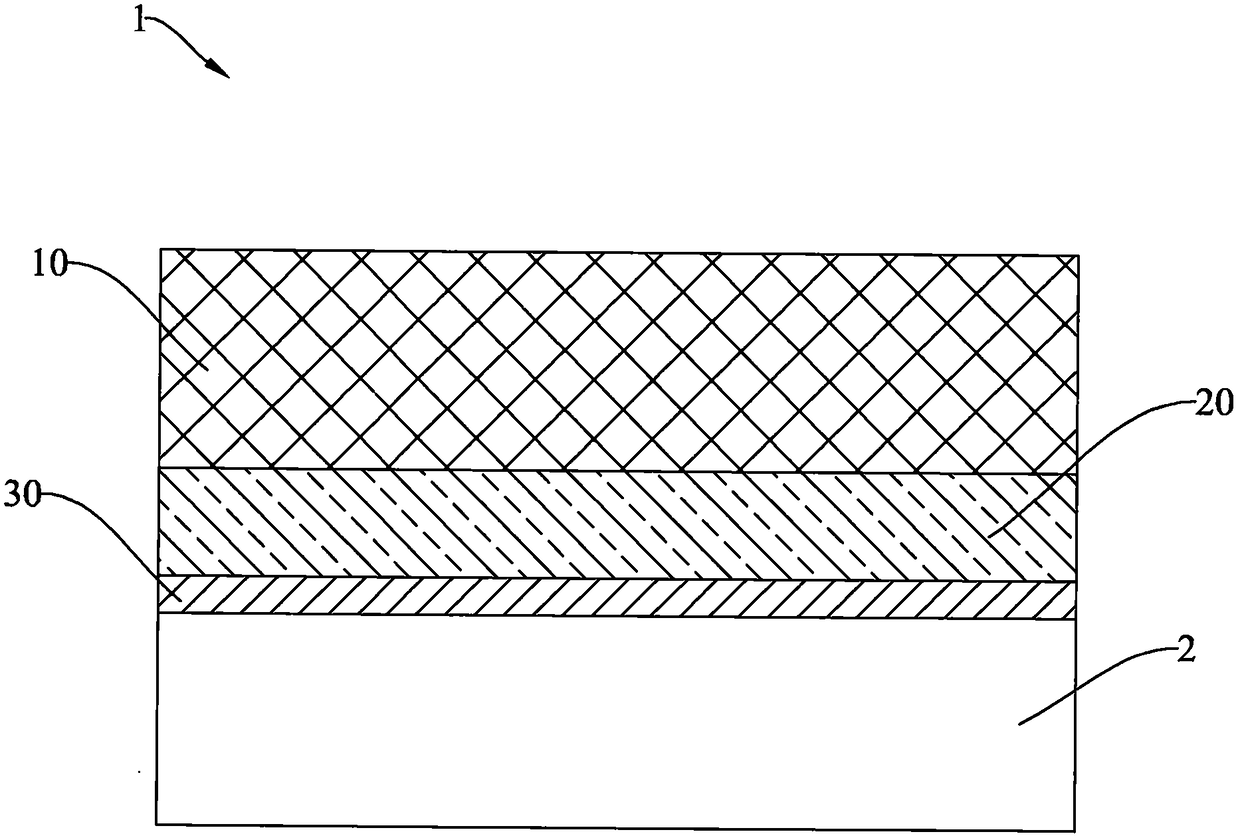

Image

Examples

preparation example Construction

[0038] The preparation method of the modified expanded vermiculite is as follows: 10g methylcellulose, 15g sodium dodecylbenzenesulfonate are dissolved in 60mL deionized water, fully stirred with a glass rod to obtain a dispersant solution, and then 100g vermiculite Pour the stone into the ball mill jar, add the previously prepared solution, stir evenly with a glass rod, put it into the planetary mill for ball milling for 2 hours, and the speed of the planetary mill is 200r / min. After the ball milling, pour the product into a glass dish, and It is placed in a vacuum drying oven for drying at a temperature of 70° C. until it is dried, and finally the dried product is pulverized with a pulverizer to obtain modified expanded vermiculite.

[0039]The modified expanded vermiculite is surface-modified expanded vermiculite. Vermiculite is a layered silicate mineral with strong thermal insulation properties. The dispersion of its mineral powder in the organic matrix determines the per...

Embodiment 1

[0052] Each component of the 10 nanometer ceramic composite material of the heat insulation layer adopts the following proportioning by weight:

[0053] 70 parts of nanoscale rare earth hollow ceramic microbeads modified epoxy resin

[0054] Modified expanded vermiculite 40 parts

[0056] The components of the auxiliary layer 20 foamed silicone / silicon dioxide hybrid coating adopt the following proportions by weight:

[0057] Silicone / silica hybrid sol matrix 70 parts

[0058] Foaming agent 8 parts

[0059] Sodium dodecyl sulfonate 1 part

[0060] Lauroyl diethanolamine 0.5 parts

[0061] Each component of the anticorrosion layer 30 modified epoxy resin primer adopts the following proportioning by weight:

[0062] 100 parts epoxy resin

[0063] Hollow glass microspheres 8 parts

[0064] The coating application steps are as follows:

[0065] 1. Clean the surface of the tank body 2 to ensure that there is no visible grease and dirt, and r...

Embodiment 2

[0070] The construction method of Example 2 is the same as that of Example 1, except that the composition of the nano-ceramic thermal insulation material 1 is different.

[0071] Each component of the 10 nanometer ceramic composite material of the heat insulation layer adopts the following proportioning by weight:

[0072] 70 parts of nanoscale rare earth hollow ceramic microbeads modified epoxy resin

[0073] Modified expanded vermiculite 30 parts

[0075] The components of the auxiliary layer 20 foamed silicone / silicon dioxide hybrid coating adopt the following proportions by weight:

[0076] Silicone / silica hybrid sol matrix 70 parts

[0077] Foaming agent 8 parts

[0078] Sodium dodecyl sulfonate 1 part

[0079] Lauroyl diethanolamine 0.5 part

[0080] Each component of the anticorrosion layer 30 modified epoxy resin primer adopts the following proportioning by weight:

[0081] 100 parts epoxy resin

[0082] Hollow glass microspheres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com