Bimetallic wear-resisting lining plate and preparation method thereof

A wear-resistant lining plate and bimetal technology, which is applied in the field of metal material casting, can solve the problems of large difference in structure stress of composite layer, large difference in alloy composition content, unstable interface bonding force, etc., to achieve high wear resistance, Low cost, strong metallurgical bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

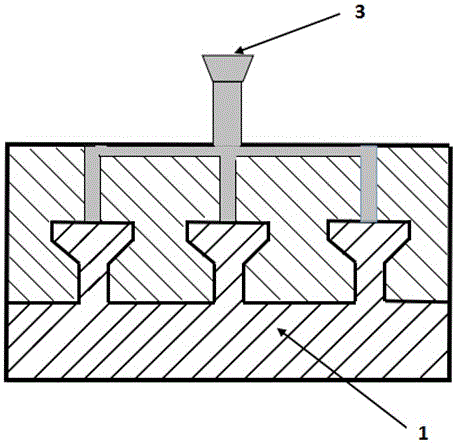

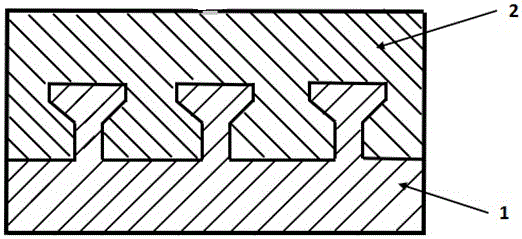

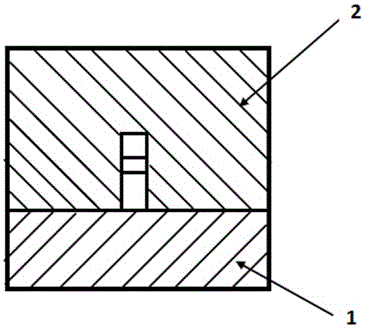

[0022] The bimetal wear-resistant liner described in this embodiment, such as figure 1 , 2 , 3, the length × width × height is 1600 × 650 × 300mm, the height of the wear-resistant layer is 75mm, the height of the base layer is 225mm, the height of the T-shaped protrusion structure is 37.5mm, there are three T-shaped protrusions, and the T-shaped The width of the widest part of the raised structure is 43.5 mm. The composition and weight percentage of the base layer and wear-resistant layer materials are shown in Table 1. The rest of the wear-resistant layer is iron and unavoidable impurities.

[0023] Table 1

[0024]

[0025] The preparation method of the bimetallic wear-resistant liner described in this embodiment specifically includes the following steps:

[0026] (1) Batching and smelting: Batching is carried out according to the components of wear-resistant layer, base layer, and T-shaped protrusions, and smelted separately by medium frequency induction furnace;

[0...

Embodiment 2

[0032] The bimetallic wear-resistant lining plate described in this embodiment has a length × width × height of 1600 × 650 × 300mm, a wear-resistant layer height of 150mm, a base layer height of 150mm, a T-shaped convex structure height of 93.7mm, and a T-shaped convex structure. The width of the widest part of the T-shaped convex structure is 54.2mm. The composition and weight percentage of the base layer and wear-resistant layer materials are shown in Table 2. The rest of the wear-resistant layer is iron and non-woven fabrics. Avoid impurities.

[0033] Table 2

[0034]

[0035] The preparation method of the I-shaped structure bimetal wear-resistant lining plate described in this embodiment specifically includes the following steps:

[0036] (1) Batching and smelting: Batching is carried out according to the components of wear-resistant layer, base layer, and T-shaped protrusions, and smelted separately by medium frequency induction furnace;

[0037] (2) Layer-by-layer ...

Embodiment 3

[0042] The bimetallic wear-resistant lining plate described in this embodiment has a length × width × height of 1600 × 650 × 300mm, a wear-resistant layer height of 125mm, a base layer height of 175mm, a T-shaped convex structure height of 104.2mm, and a T-shaped convex structure. The width of the widest part of the T-shaped convex structure is 81.25mm. The composition and weight percentage of the base layer and wear-resistant layer materials are shown in Table 3. The rest of the wear-resistant layer is iron and unavoidable. Impurities.

[0043] table 3

[0044]

[0045] The preparation method of the I-shaped structure bimetal wear-resistant lining plate described in this embodiment specifically includes the following steps:

[0046] (1) Batching and smelting: Batching is carried out according to the components of wear-resistant layer, base layer, and T-shaped protrusions, and smelted separately by medium frequency induction furnace;

[0047] (2) Layered casting molding: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com