Foamed aluminum sound reflecting cover

A technology of foamed aluminum and foamed aluminum boards, applied in building components, thermal insulation, sound insulation, etc., can solve the problems of easy falling off of flame-retardant boards and aluminum honeycomb core sandwich boards, small composite area of flame-retardant boards, and insufficient elastic recovery force, etc., to achieve Good anti-moth effect, good fireproof effect, light and thin structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

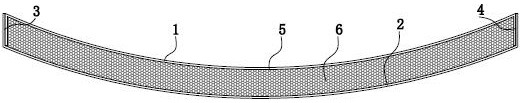

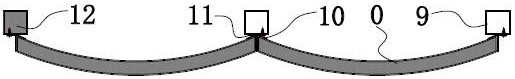

[0024] Such as Figure 1 to Figure 3 As shown, a foamed aluminum acoustic enclosure preferably implemented in the present invention includes an acoustic enclosure and a lightweight filling core, and is characterized in that the acoustic enclosure includes a front cover made of metal materials, The rear cover, the left cover, the right cover, and the filling cavity surrounded by the front cover, the rear cover, the left cover and the right cover, the width of the filling cavity is 5mm~20mm; the lightweight The filling core is disposed in the filling cavity.

[0025] Preferably, the lightweight filling core is a foamed aluminum plate made by adding additives to pure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com