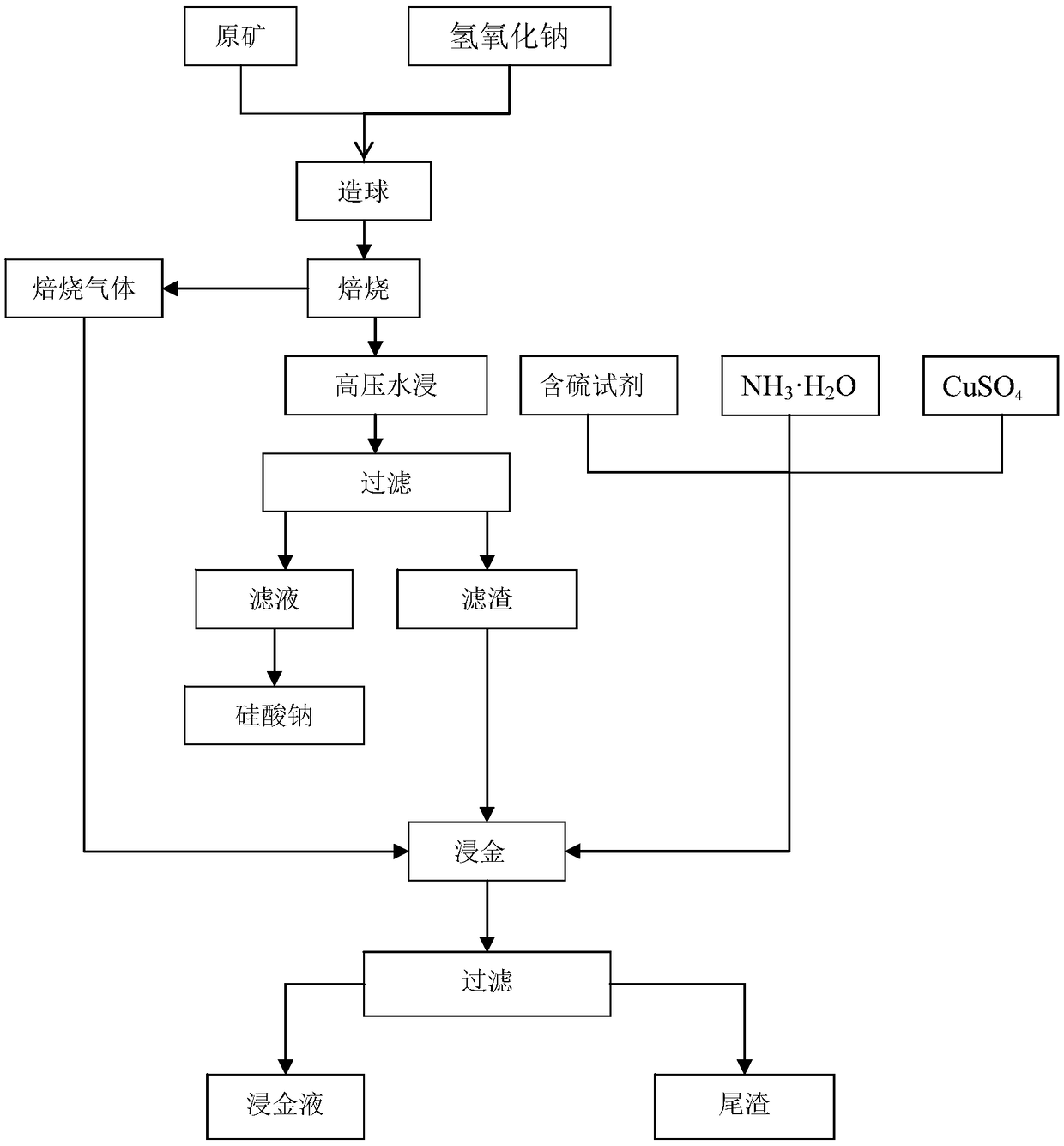

A method for comprehensive clean recovery of gold, carbon, sulfur and silicon in carbonaceous gold ore

A technology of silicon element and gold ore, which is applied in the treatment field of carbon-containing gold ore, can solve problems such as ineffective treatment, and achieve the effects of improving gold leaching efficiency, broad application prospects and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A carbon-bearing gold mine in Sichuan, the chemical multi-element analysis results of the carbon-gold mine are as follows (%):

[0029] TC

Au*

SiO 2

S

As

Mg

Al

P

K

Fe

Cu

Zn

18.2

30.32

57.57

6.02

0.07

0.03

5.6

0.98

1.1

3.85

0.08

0.53

[0030] *Unit: g / t

[0031] Grind the carbon-gold ore for 10 minutes, the carbon-gold ore-400 mesh accounts for 8wt%, mix the ground carbon-gold ore and sodium hydroxide in a mass ratio of 4:3 and add 8% of the total mass of deionized water Stir evenly; press the mixed sample into balls, and the weight of a single ball is about 50g.

[0032] The pressed balls are first dried in an oven, then transferred to a muffle furnace and roasted at a temperature of 750°C for 2 hours; after the roasted carbon gold ore is cooled, it is fully pulverized in a high-speed universal pulverizer; after pulverization, it is transferred to a high-pressure Deionized w...

Embodiment 2

[0034] A carbon-bearing gold mine in Guizhou, the chemical multi-element elemental analysis results of the carbon-gold mine are as follows (wt%):

[0035] TC

Au*

SiO 2

S

As

Fe

mn

Ca

Mg

Al

K

16.45

28.67

58.66

1.53

0.26

2.64

0.12

2.99

0.97

3.89

1.17

[0036] *Unit: g / t

[0037] Grind carbon-gold ore for 10 minutes, carbon-gold ore-400 mesh accounts for 10wt%, mix the ground carbon-gold ore and sodium hydroxide in a mass ratio of 3:2 and add 10% of the total mass of deionized water Stir evenly; press the mixed sample into balls, and the weight of a single ball is about 50g.

[0038] Dry the pressed balls in an oven first, then transfer them to a muffle furnace and roast them at 700°C for 2.5 hours; after the roasted carbon gold is cooled, it is fully pulverized in a high-speed universal pulverizer; after pulverization, it is transferred to an autoclave Deionized water was added to the mixtu...

Embodiment 3

[0040] A gold concentrate of a carbon-bearing gold mine in Yunnan, the chemical multi-element analysis results of the carbon-gold mine are as follows (wt%):

[0041] TC

Au*

SiO 2

S

Fe

Cu

As

Ca

Mg

19.56

31.89

39.19

18.81

11.12

0.103

2.01

2.39

3.26

[0042] *Unit: g / t

[0043] Grind the carbon-gold ore for 10 minutes, carbon-gold ore-400 mesh accounts for 20wt%, mix the ground carbon-gold ore and sodium hydroxide in a mass ratio of 5:3 and add 8% of the total mass of deionized water Stir evenly; press the mixed sample into balls, and the weight of a single ball is about 50g.

[0044]Dry the pressed balls in an oven first, then transfer them to a muffle furnace and roast them at a temperature of 650°C for 2 hours; after the roasted carbon gold is cooled, it is fully pulverized in a high-speed universal pulverizer; after pulverization, it is transferred to an autoclave Deionized water was added to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com