Antistatic sheet and preparation method thereof

An antistatic and antistatic liquid technology, applied in conductive coatings, coatings, etc., can solve problems such as the influence of environmental humidity, the risk of carbon powder dropping, and low surface resistivity, and achieve long-lasting and effective antistatic effects and good antistatic effects , the effect of high heat deformation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

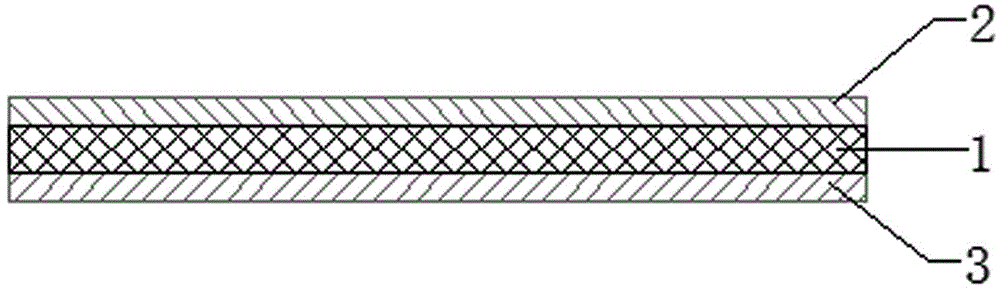

[0045] An antistatic sheet, comprising a polyolefin sheet, and a permanent polymer antistatic layer coated on one side of the polyolefin sheet; the total thickness of the antistatic sheet is 0.15mm, and the permanent The thickness of the polymer antistatic layer is 0.5um. The following are all by mass, the polyolefin sheet contains polypropylene, and also contains 5% calcium carbonate filler masterbatch and 0.2% toner; the permanent polymer antistatic layer is a permanent antistatic polymer layer containing The antistatic liquid of the antistatic agent is formed after drying and curing; the permanent polymer antistatic agent is polyaniline, and the content of polyaniline in the antistatic liquid is 5%, and the antistatic liquid contains polyaniline and thermosetting A water-based coating solution of resin; the antistatic solution contains an adhesion promoter, and the adhesion promoter contains an amino-modified silane compound.

Embodiment 2

[0047] An antistatic sheet, comprising a polyolefin sheet, and a permanent polymer antistatic layer coated on one side of the polyolefin sheet; the total thickness of the antistatic sheet is 1.5mm, and the permanent The thickness of the polymer antistatic layer is 5um. The following are all based on mass, the polyolefin sheet contains polyethylene, and also contains 10% talcum powder filler masterbatch, 2% pigment, and a total of 1% of known lubricants, antioxidants, toughening The processing aid of the agent; the permanent macromolecular antistatic layer is formed after the antistatic liquid containing the macromolecule permanent antistatic agent is dried and solidified; the macromolecule permanent antistatic agent is polypyrrole, and polypyrrole is in The content in the antistatic liquid is 10%, and the antistatic liquid is a solvent-based coating liquid containing polypyrrole and a thermosetting resin; the antistatic liquid does not contain an adhesion promoter, and the pol...

Embodiment 3

[0049] A kind of antistatic sheet material, comprises polyolefin sheet material, and the permanent macromolecule antistatic layer that is coated on described polyolefin sheet material both sides; The total thickness of described antistatic sheet material is 2.5mm, and described permanent The thickness of the polymer antistatic layer is 8um. The following are all based on mass, the polyolefin sheet contains a mixture of polypropylene and polyethylene, and also contains 15% calcium carbonate and talcum powder filler masterbatch, 1% color masterbatch, and a total of 2.5% known A processing aid comprising a lubricant, an antioxidant, and a toughening agent; the permanent polymer antistatic layer is formed after drying and curing of an antistatic liquid containing a permanent polymer antistatic agent; the permanent polymer antistatic layer The antistatic agent is polythiophene, and the content of polythiophene in the antistatic liquid is 15%, and the antistatic liquid is a solvent-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com