Building material environment-friendly, flame-retardant and acid-alkali-resistant treatment coating

A building material, acid and alkali resistance technology, used in coatings, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of difficult absorption, poor sound absorption performance, etc., to achieve superior flame retardant and improve product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

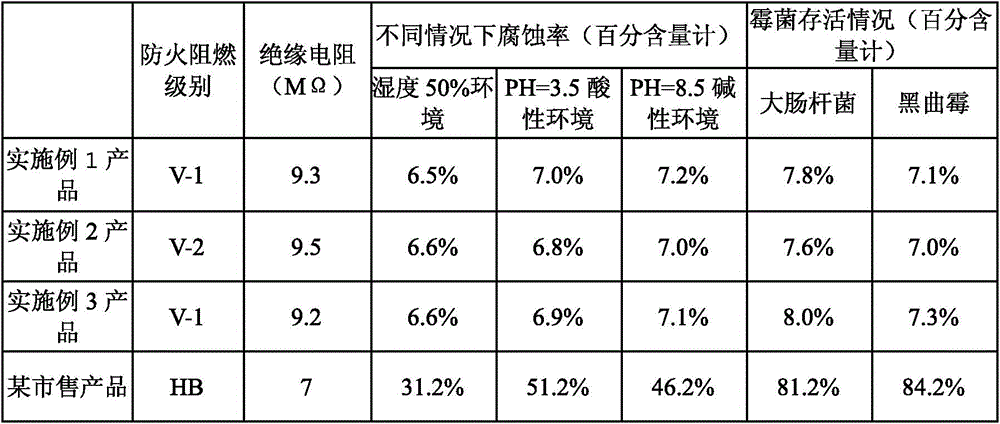

Embodiment 1

[0016] The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 18 parts of phenyltriethoxysilane, 16 parts of lithium phosphate powder, 16 parts of sodium fatty acid, soybean oil 14 parts, 16 parts of chlorothalonil, 16 parts of camellia powder, 14 parts of zinc sulfide powder, 16 parts of jade powder, 16 parts of asbestos powder, 14 parts of hydrogenated nitrile rubber, 14 parts of aluminum distearate, 14 parts of sucrose, benzene 16 parts of ethylene-butadiene-styrene block copolymer, 14 parts of fluororubber, 12 parts of polyacrylonitrile fiber, 16 parts of hexahydrophthalic anhydride, 14 parts of n-butyl titanate, ethyl p-hydroxybenzoate 12 parts of ester, 14 parts of trichloroisocyanuric acid, 12 parts of menthol, 12 parts of 5-aminobenzimidazolone, 14 parts of tourmaline powder, 14 parts of molybdenum disilicide powder, 14 parts of ferric chlo...

Embodiment 2

[0022] The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 20 parts of phenyltriethoxysilane, 18 parts of lithium phosphate powder, 18 parts of sodium fatty acid, soybean oil 16 parts, 18 parts of chlorothalonil, 18 parts of camellia powder, 16 parts of zinc sulfide powder, 18 parts of jade powder, 18 parts of asbestos powder, 16 parts of hydrogenated nitrile rubber, 16 parts of aluminum distearate, 16 parts of sucrose, benzene 18 parts of ethylene-butadiene-styrene block copolymer, 16 parts of fluororubber, 14 parts of polyacrylonitrile fiber, 18 parts of hexahydrophthalic anhydride, 16 parts of n-butyl titanate, ethyl p-hydroxybenzoate 14 parts of ester, 16 parts of trichloroisocyanuric acid, 14 parts of menthol, 14 parts of 5-aminobenzimidazolone, 16 parts of tourmaline powder, 16 parts of molybdenum disilicide powder, 16 parts of ferric chlo...

Embodiment 3

[0028] The environmental-friendly, flame-retardant, acid- and alkali-resistant treatment coating for building materials in this embodiment consists of the following components in parts by mass: 22 parts of phenyltriethoxysilane, 20 parts of lithium phosphate powder, 20 parts of sodium fatty acid, soybean oil 18 parts, chlorothalonil 20 parts, camellia powder 20 parts, zinc sulfide powder 18 parts, jade powder 20 parts, asbestos powder 20 parts, hydrogenated nitrile rubber 18 parts, aluminum distearate 18 parts, sucrose 18 parts, benzene 20 parts of ethylene-butadiene-styrene block copolymer, 18 parts of fluororubber, 16 parts of polyacrylonitrile fiber, 20 parts of hexahydrophthalic anhydride, 18 parts of n-butyl titanate, ethyl p-hydroxybenzoate 16 parts of ester, 18 parts of trichloroisocyanuric acid, 16 parts of menthol, 16 parts of 5-aminobenzimidazolone, 18 parts of tourmaline powder, 18 parts of molybdenum disilicide powder, 18 parts of ferric chloride, 18 parts of oxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com