Soft high-specific-gravity rubber-plastic foam material for insulating sound and reducing noise

A rubber-plastic foam material, sound insulation and noise reduction technology, applied in the field of polymer foam materials, can solve the problems of inability to overcome the resonance frequency and the sound insulation trough of the matching effect, the sound insulation effect is not ideal, and it is difficult to process and use. Good sound insulation and mechanical properties, good sound insulation and damping properties, the effect of increasing areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix each component in the following proportions on an open mill evenly, and mold it into a 7 mm soft foam material, and its weighted sound insulation is about 32dB.

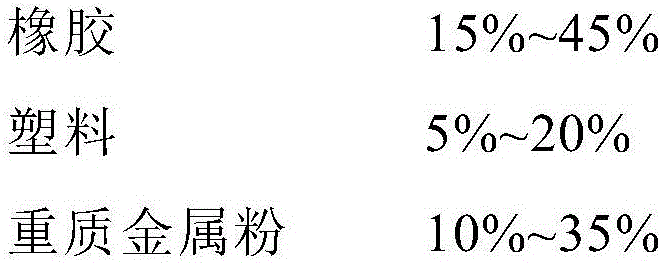

[0025] High molecular polymer: 50% (polystyrene: 15%, nitrile rubber: 35%), iron powder (0.1 micron): 20%, monoalkoxy tris (dioctylphosphoryloxy) titanate : 5%, dibutyl phthalate: 5%, sulfur: 5%; azodicarbonamide: 9%; N-cyclohexyl-2-benzothiazole sulfenamide: 2%; stearic acid Barium: 2%, lead sulfate tribasic: 2%.

Embodiment 2

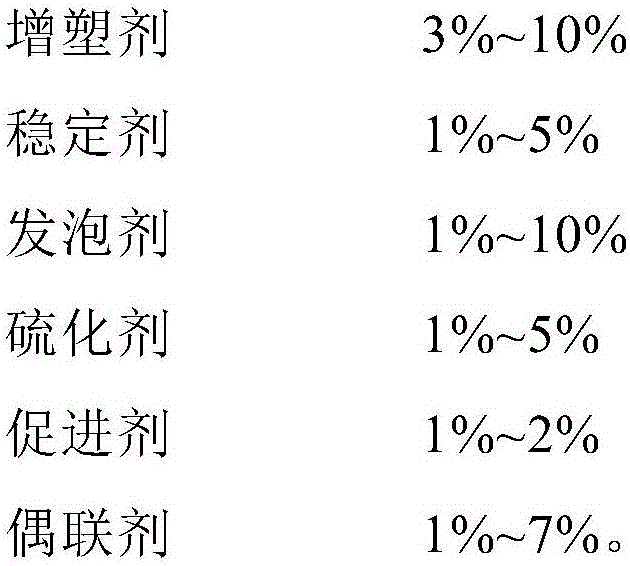

[0027] The following ingredients are mixed evenly on the open mill, molded into a 6mm soft foam material, which forms a sandwich structure with the gypsum board, and its sound insulation is between 34 and 36 decibels (specifically, each center The sound insulation at the frequency is shown in the table below).

[0028] Nitrile rubber: 35%, polyvinyl chloride: 20%, tungsten powder (10 microns): 30%, isopropyl tricarboxy titanate: 1%, dibutyl phthalate: 3%, stearic acid Barium: 0.5%, lead sulfate tribasic: 0.5%; sulfur: 4%; azodicarbonamide: 5%; N-cyclohexyl-2-benzothiazole sulfenamide: 1%.

[0029] Center frequency [Hz]

Embodiment 3

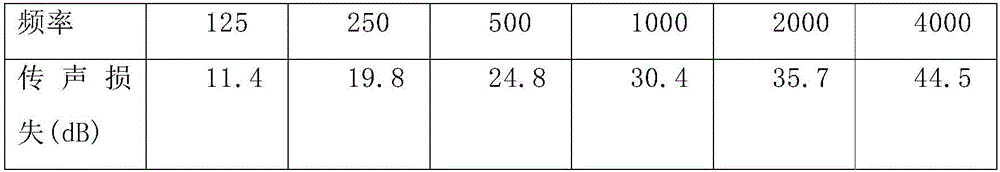

[0031] The following ingredients are mixed evenly on the open mill, and molded into a 6 mm soft foam material, which has good anti-aging ability, and its average sound insulation is about 30 decibels, and its sound insulation is shown in the following table Show.

[0032] High molecular polymer: 45% (neoprene rubber: 35%; polyvinyl chloride: 10%), copper powder (10 microns): 25%, monoalkoxy tris (dioctylphosphoryloxy) titanate : 5%, dibutyl phthalate: 8%, barium stearate: 1%; sulfur: 5%; azodicarbonamide: 5%; N-cyclohexyl-2-benzothiazole sulfen Amide: 2%; Zinc Stearate: 2%, Lead Sulfate Tribasic: 2%.

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com