Flame retardation and antibiosis fabric

A kind of antibacterial fabric and fabric technology, which is applied in the direction of fireproof coating, antifouling/underwater coating, coating, etc., can solve the problems of easy wrinkle and deformation, and achieve the effect of improving product performance and superior flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

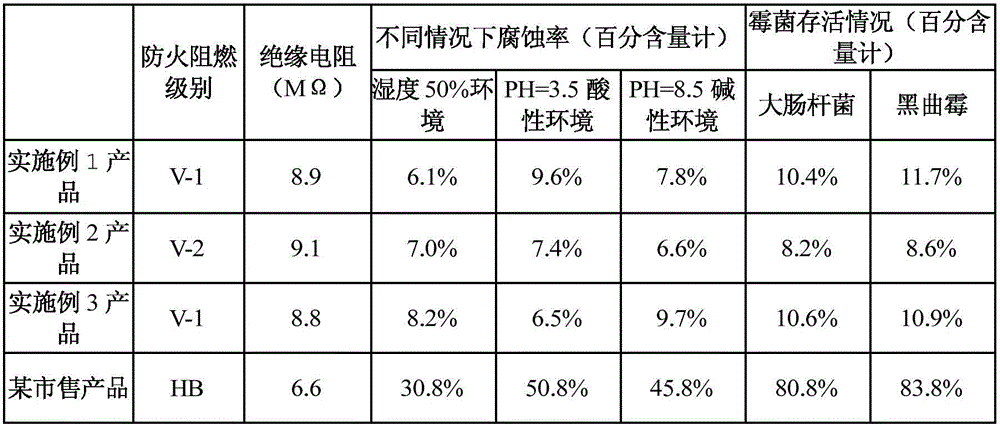

Examples

Embodiment 1

[0016] The flame-retardant and antibacterial fabric in this embodiment is bonded with a protective coating on the linen fabric, and the coating is composed of the following components in parts by mass: 18 parts of a-olefin elastomer, 16 parts of polymethyl methacrylate , 16 parts of isoprene rubber, 14 parts of tall oil fatty acid, 16 parts of butyl acetate, 16 parts of allyl sulfide, 14 parts of diethylene glycol ethyl ether, 16 parts of diethylene glycol butyl ether, 16 parts of propiconazole, 14 parts of sodium monofluorophosphate, 14 parts of dodecyl ethoxy sulfobetaine, 14 parts of dimethyl fumarate, 16 parts of cuprous chloride, 14 parts of metatitanic acid, 12 parts of silicon carbide fiber, benzene 16 parts of triethoxysilane, 14 parts of chromium oxide green, 12 parts of chromium chloride, 14 parts of barium chromate powder, 12 parts of sodium cellulose, 12 parts of trimethyl phosphate, 14 parts of polyacrylonitrile fiber, disalt 14 parts of basic lead stearate, 14 pa...

Embodiment 2

[0022] The flame-retardant and antibacterial fabric in this embodiment is bonded with a protective coating on the linen fabric, and the coating is composed of the following components in parts by mass: 20 parts of α-olefin elastomer, 18 parts of polymethyl methacrylate , 18 parts of isoprene rubber, 16 parts of tall oil fatty acid, 18 parts of butyl acetate, 18 parts of allyl sulfide, 16 parts of diethylene glycol ethyl ether, 18 parts of diethylene glycol butyl ether, 18 parts of propiconazole, 16 parts of sodium monofluorophosphate, 16 parts of dodecyl ethoxy sulfobetaine, 16 parts of dimethyl fumarate, 18 parts of cuprous chloride, 16 parts of metatitanic acid, 14 parts of silicon carbide fiber, benzene 18 parts of triethoxysilane, 16 parts of chromium oxide green, 14 parts of chromium chloride, 16 parts of barium chromate powder, 14 parts of sodium cellulose, 14 parts of trimethyl phosphate, 16 parts of polyacrylonitrile fiber, disalt 16 parts of basic lead stearate, 16 pa...

Embodiment 3

[0028] The flame-retardant and antibacterial fabric in this embodiment is bonded with a protective coating on the linen fabric, and the coating is composed of the following components in parts by mass: 22 parts of α-olefin elastomer, 20 parts of polymethyl methacrylate , 20 parts of isoprene rubber, 18 parts of tall oil fatty acid, 20 parts of butyl acetate, 20 parts of allyl sulfide, 18 parts of diethylene glycol ethyl ether, 20 parts of diethylene glycol butyl ether, 20 parts of propiconazole, 18 parts of sodium monofluorophosphate, 18 parts of dodecyl ethoxy sulfobetaine, 18 parts of dimethyl fumarate, 20 parts of cuprous chloride, 18 parts of metatitanic acid, 16 parts of silicon carbide fiber, benzene 20 parts of triethoxysilane, 18 parts of chromium oxide green, 16 parts of chromium chloride, 18 parts of barium chromate powder, 16 parts of sodium cellulose, 16 parts of trimethyl phosphate, 18 parts of polyacrylonitrile fiber, di-salt 18 parts of basic lead stearate, 18 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com